Cooling system of server cabinet

A server cabinet and cooling system technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve problems such as reducing equipment service life, server equipment failure, circuit board short circuit, etc., to speed up heat dissipation Speed, improve cooling effect, ensure stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

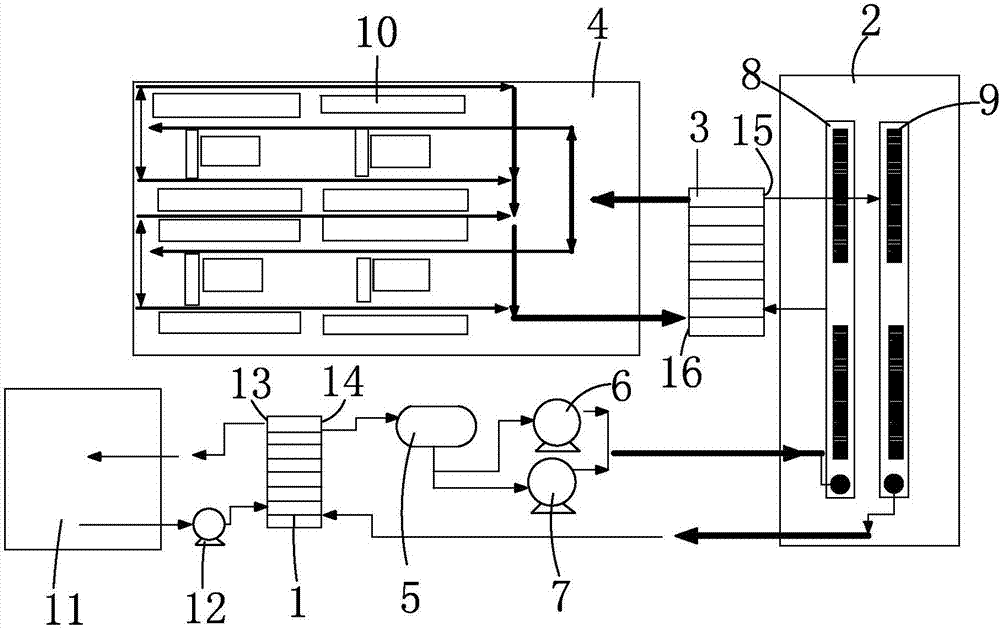

[0019] The specific implementation manner of the technical solution will be explained in detail below in conjunction with the accompanying drawings.

[0020] A cooling system for a server cabinet, comprising a cold water distribution control unit, a water manifold 2, a second cooler 3, and a server cooling circuit 4, the cold water distribution control unit includes a first cooler 1, a water pump 6, and the diversity The water device 2 includes a water separator 8, a water collector 9, the cooling medium pipeline side 14 of the first cooler, a water pump 6, a water separator 8, a water collector 9, and the cooling medium pipeline of the second cooler The side 15 is connected by a pipeline to form a first circulation pipeline, and the cooled medium pipeline side 16 of the second cooler and the server cooling circuit 4 are connected by a pipeline to form a second circulation pipeline, and in the second circulation pipeline The cooling medium is electronic fluorinated liquid, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com