Improved type paint brushing equipment

An improved and equipment-based technology, which is applied in the field of painting, can solve the problems of high labor intensity of workers, poor precision of painting work, automatic isolation of materials, etc., and achieve the effect of improving the precision of painting work, precise painting work and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

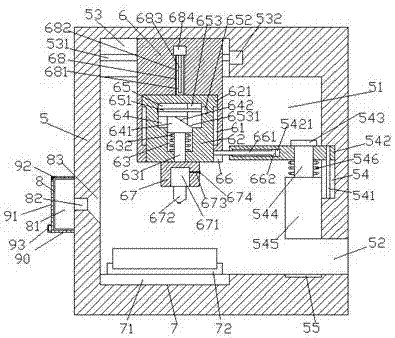

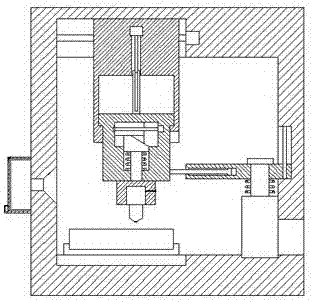

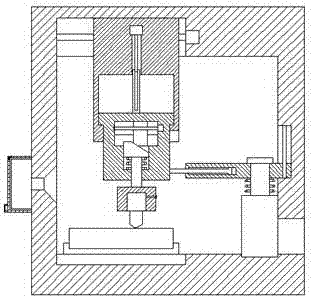

[0025] Such as Figure 1-Figure 5 As shown, a kind of improved painting equipment of the present invention comprises frame 5, and described frame 5 is provided with painting chamber 51, and the left side of the top inside described painting chamber 51 is provided with first movable groove 53, so The right side of the painting chamber 51 is provided with a second movable groove 54, and the right side of the frame 5 below the second movable groove 54 is provided with an entrance and exit 52 connected to the left end of the paint chamber 51. The left and right sides of the inner bottom of the brushing chamber 51 are respectively provided with a socket device 7 and a counterbore 55, and the first movable groove 53 is provided with a first stud 531 elongated left and right, and the first stud 531 The upper thread is fitted with a movable block 6 whose bottom pushes into the paint brushing chamber 51. The movable block 6 is provided with a first movable chamber 61, and the first mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com