Tank cleaning machine

A cleaning machine and cleaning brush technology, applied in the direction of electrostatic cleaning, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of large dust pollution, small processing capacity, tank damage, etc., and achieve the effect of low dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

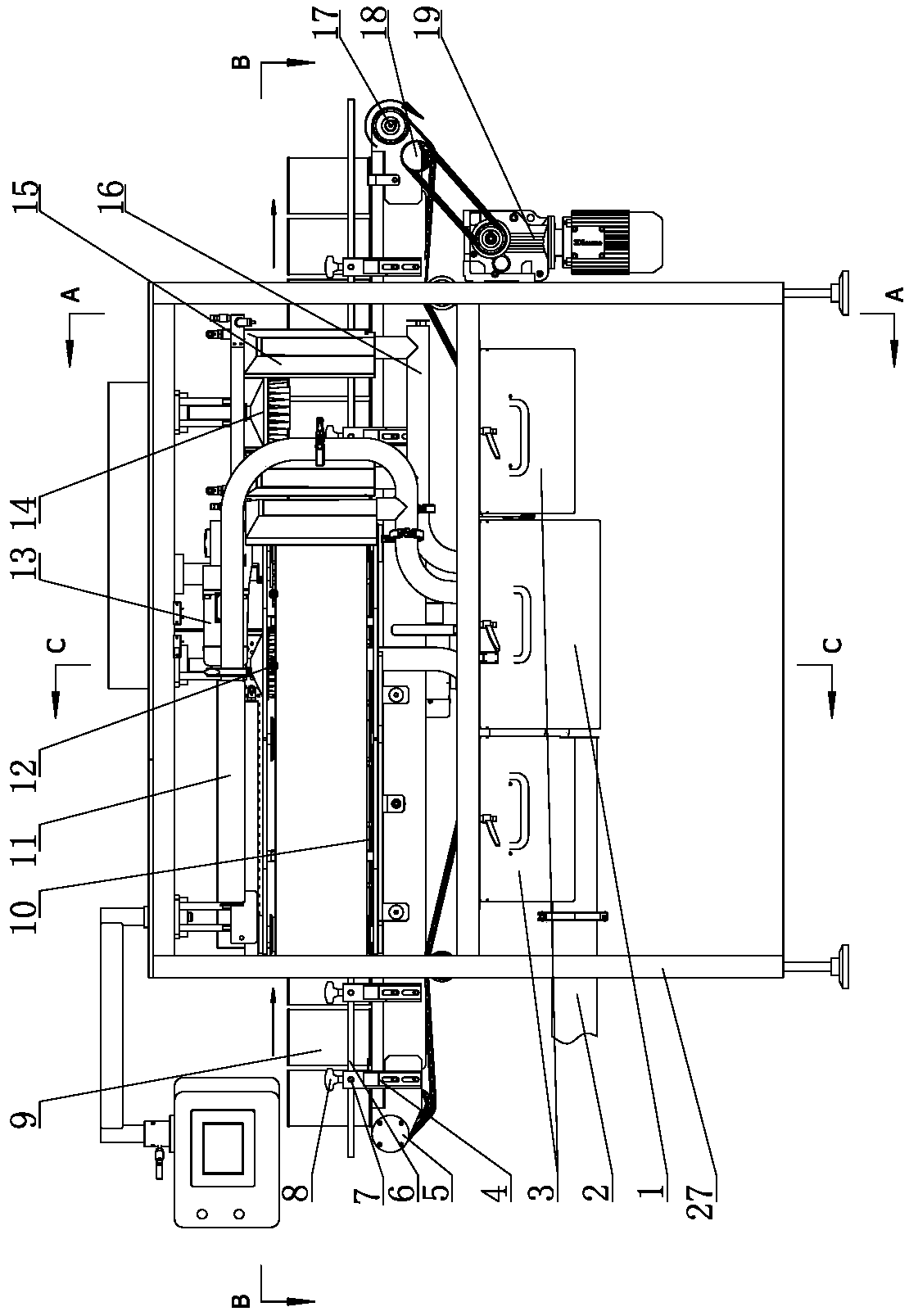

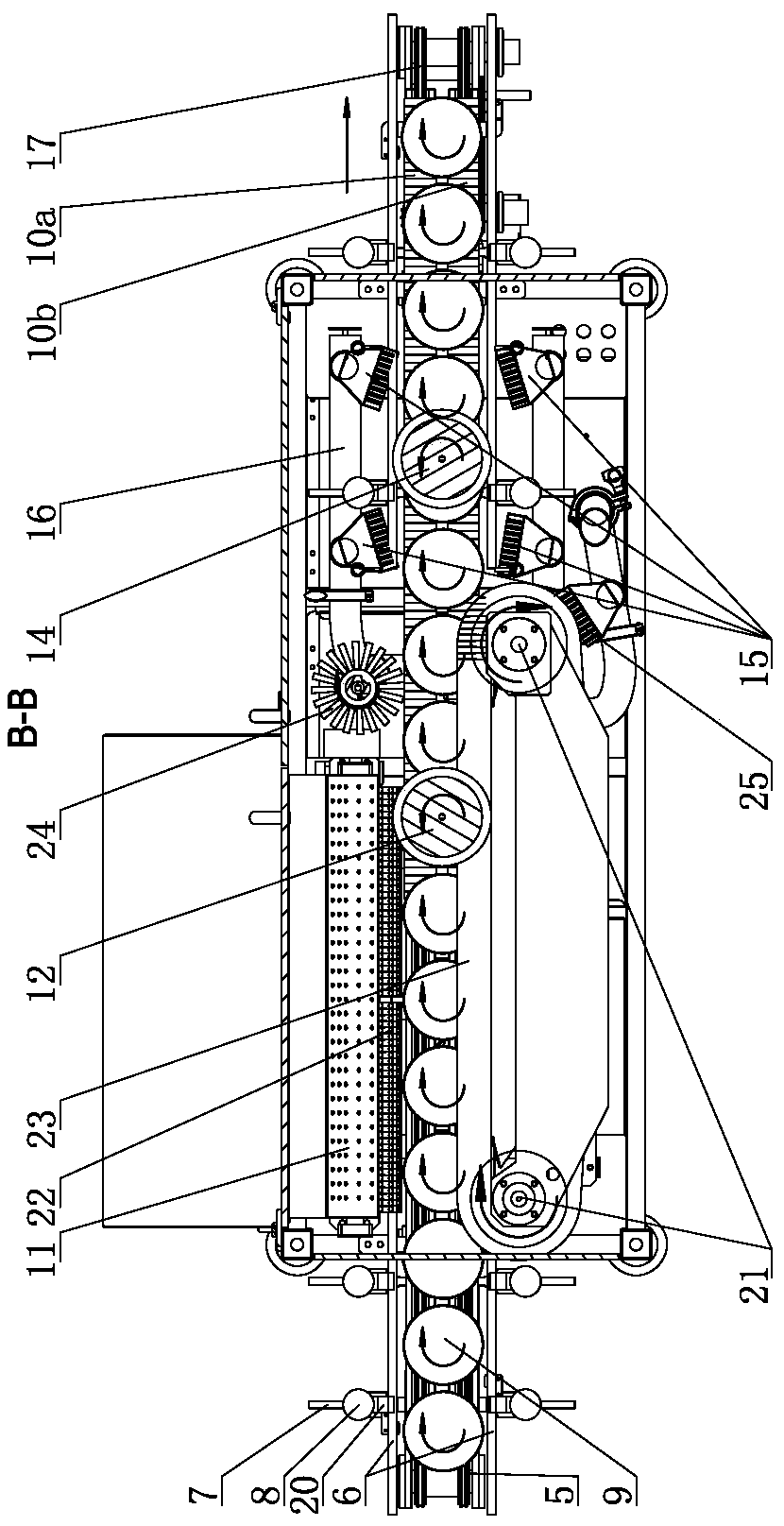

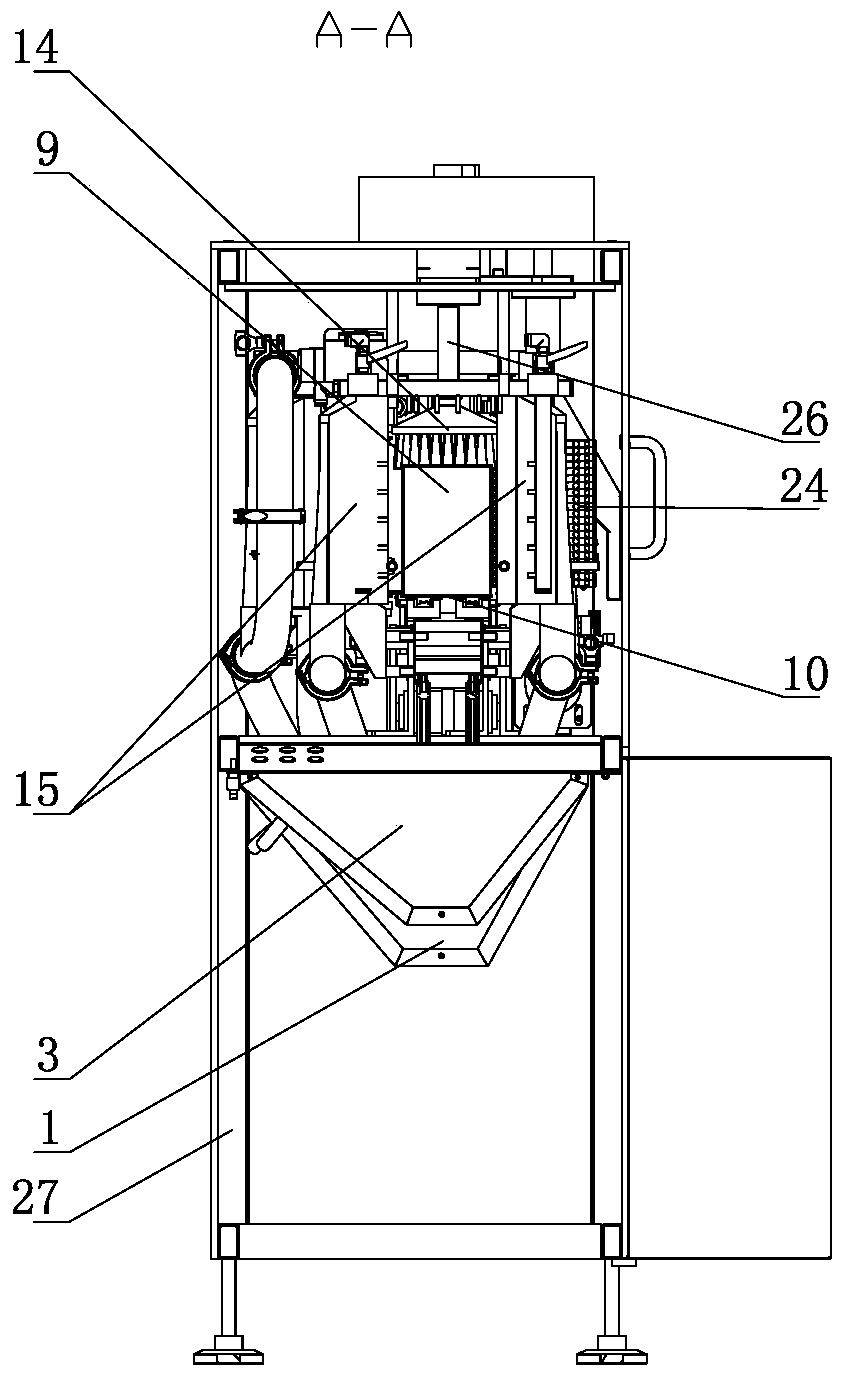

[0028] Such as Figure 1-11 As shown, it is a tank cleaning machine with a conveyor system, a purge cleaning system and a dust collection system installed on the frame 27; the conveyor system includes a conveyor belt 10 for conveying the tank body 9, and the conveyor belt 10 includes a parallel arrangement And there is a speed difference between the slow belt 10b and the fast belt 10a. The slow belt 10b and the fast belt 10a are respectively wound end to end on a number of pulleys and connected to the corresponding main drive mechanism 19. The slow belt 10b and the fast belt The upper surface of the whole 10a is at the same level, so that the tank body 9 can be placed upright on the conveyor belt 10 for transportation; the upper two sides of the conveyor belt 10 are respectively provided with stop rods 6, and a number of stop rods 6 are provided in the length direction. A chuck 20 for clamping the stop rod 6, an adjusting screw 7 is rotatably provided on the chuck 20, a stop ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com