Automatic welding method used for heat exchanger and device for automatic welding method

An automatic welding and heat exchanger technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve problems such as unfavorable enterprise development, large number of defective products, easy positioning deviation, etc., and achieve fast and accurate positioning. Determining the effect of convenient, quick and efficient welding results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

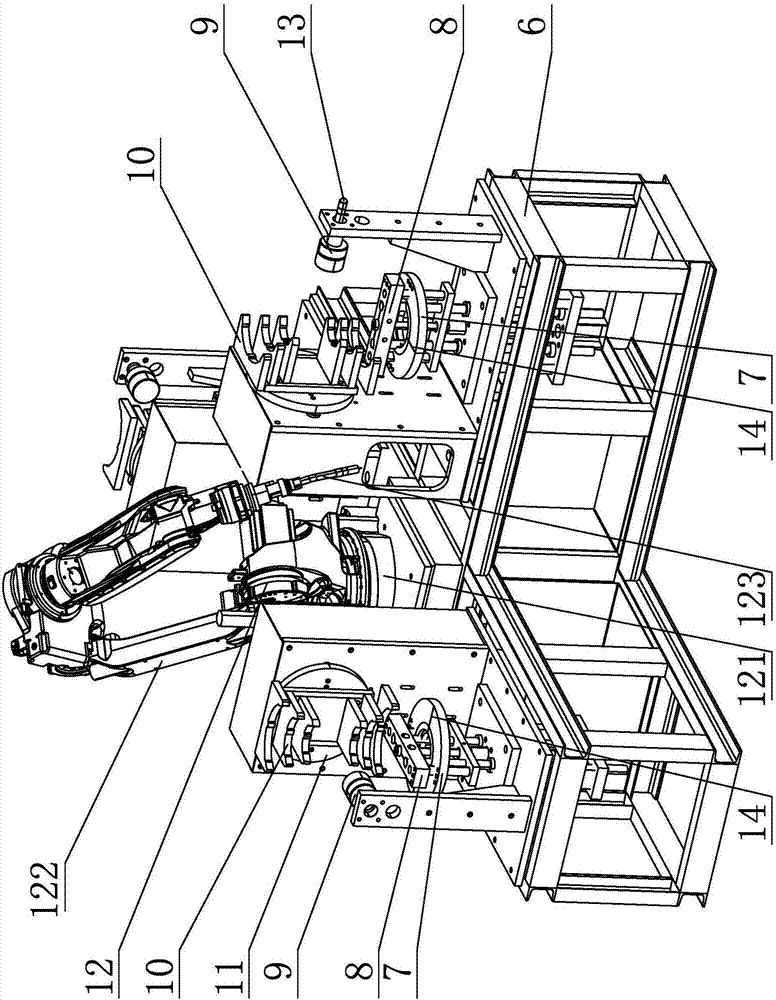

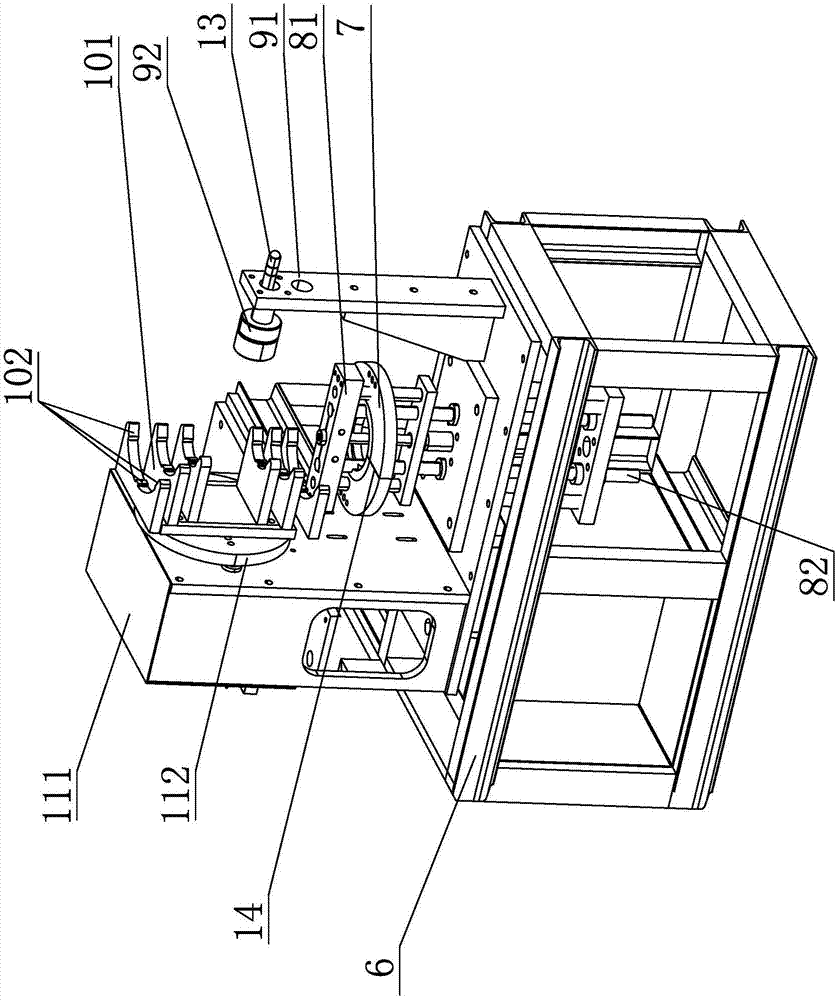

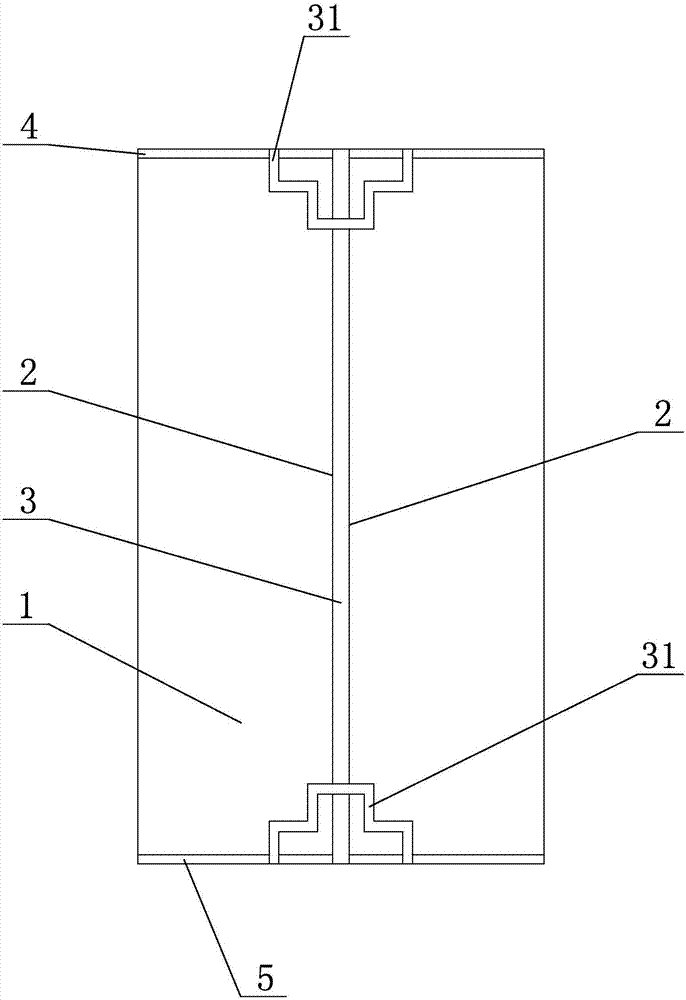

[0031] The present invention will be further described below in conjunction with the accompanying drawings, according to Figure 1 to Figure 5 As shown, in the automatic welding method for heat exchangers of the present invention, the heat exchanger includes a heat exchange preform 1, and the heat exchange preform 1 has a cylindrical straight seam 3, a cylindrical head circumferential seam 4, and a cylindrical bottom cover. Circumferential seam 5, the automatic welding method includes the following steps:

[0032] 1) Prepare limit line 2; prepare limit line 2 on both sides of the cylinder straight seam 3 of the heat exchange preform 1, on both sides of the cylinder head circumferential seam 4, and on both sides of the cylinder bottom cover circumferential seam 5 respectively .

[0033] 2) The heat exchange preform 1 is positioned on the tooling; the heat exchange preform 1 is installed on the tooling equipment, and the straight seam 3 of the cylinder body is docked with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com