Prefabricated stair and construction method thereof

A technology of prefabricated assembly and construction method, applied in the direction of stairs, buildings, building structures, etc., to achieve the effect of easy quality, complete and beautiful appearance, and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

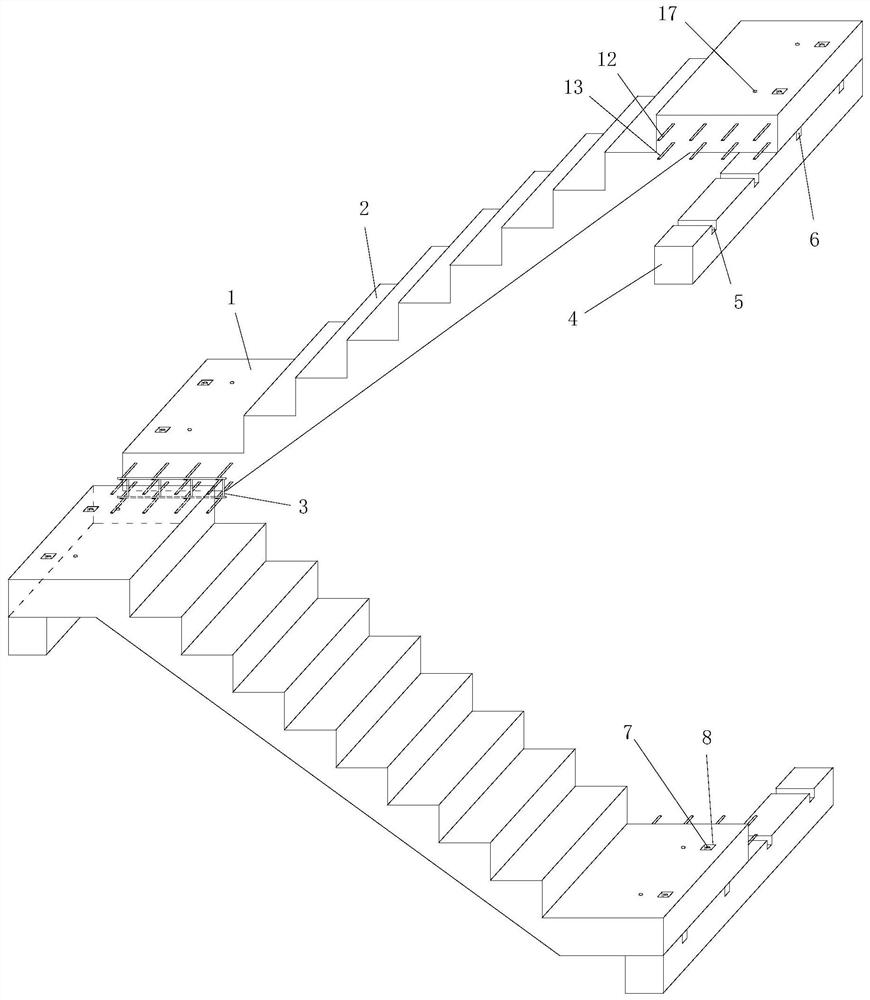

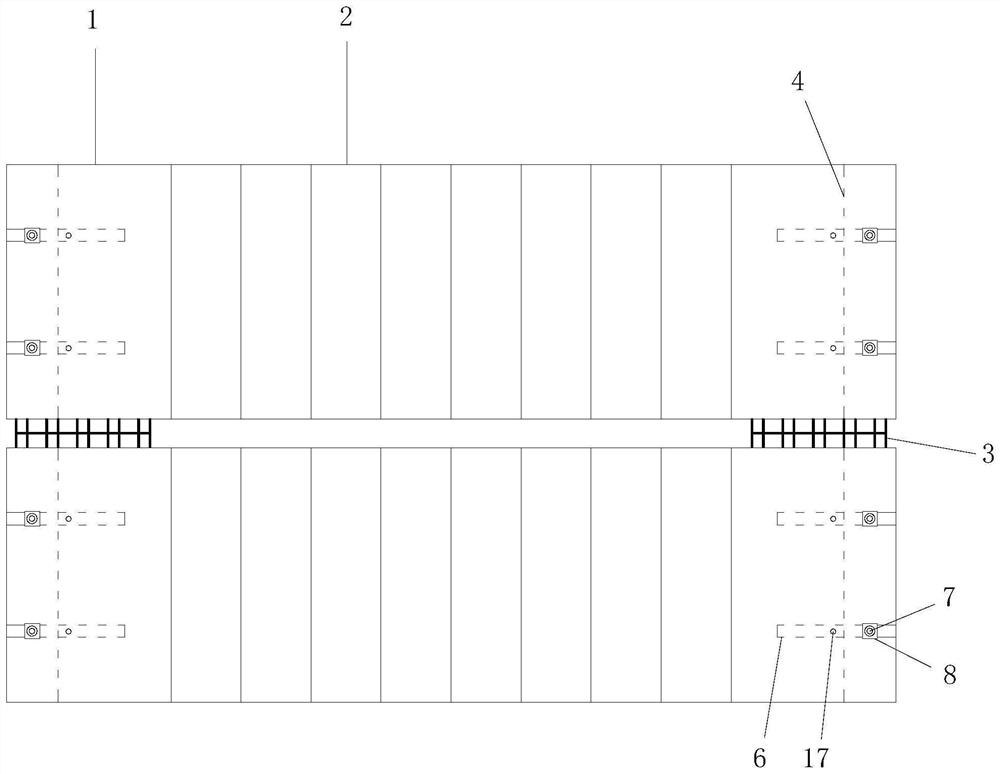

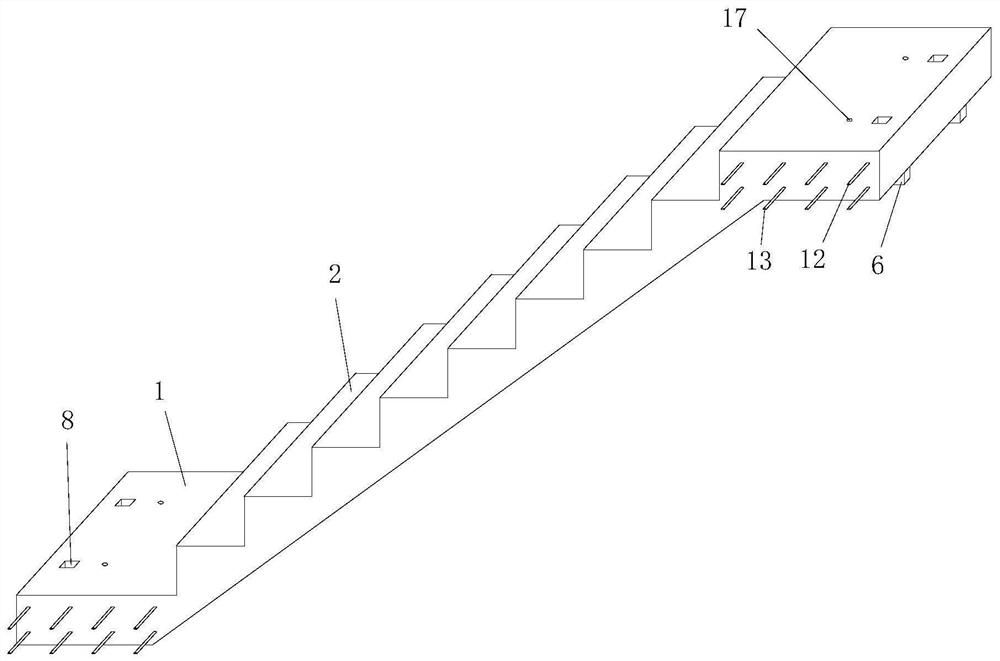

[0037] Such as Figure 8 Shown, this prefabricated assembly type staircase construction method comprises the following steps ( Figure 8 The brief steps are shown in , and the specific steps are subject to the content disclosed in the manual):

[0038] S100. According to the design requirements, the stair section 2 and the upper and lower rest platforms 1 are manufactured in the same batch in the manufacturing project, and one stair section 2 and two rest platforms 2 are used as a prefabricated unit to form a prefabricated assembly staircase hoisting unit, and at the construction site. The stair beam 4 is constructed; the construction period can be greatly reduced like this.

[0039] Among them, such as image 3 As shown, the lower part of the rest platform 1 is provided with two rib beams 6, and the upper stress rib 12 and the lower stress rib 13 are extended from the side of the rest platform 1, and the end of each rib beam 6 is provided with a reserved Bolt hole 8. Each...

Embodiment 2

[0049] The prefabricated assembled staircase is manufactured by using the construction method of the prefabricated assembled staircase in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com