A permanent ferrite magnetic tile cemented carbide mold and its assembly method

A permanent magnet ferrite and cemented carbide technology, which is applied in the manufacture of mold separation devices, molds, inductors/transformers/magnets, etc., can solve the problems of poor thermal expansion and contraction stability of stainless steel, easy loosening and falling off of alloys, and large actual errors. , to avoid excessive shrinkage changes, improve accuracy and quality, and avoid the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

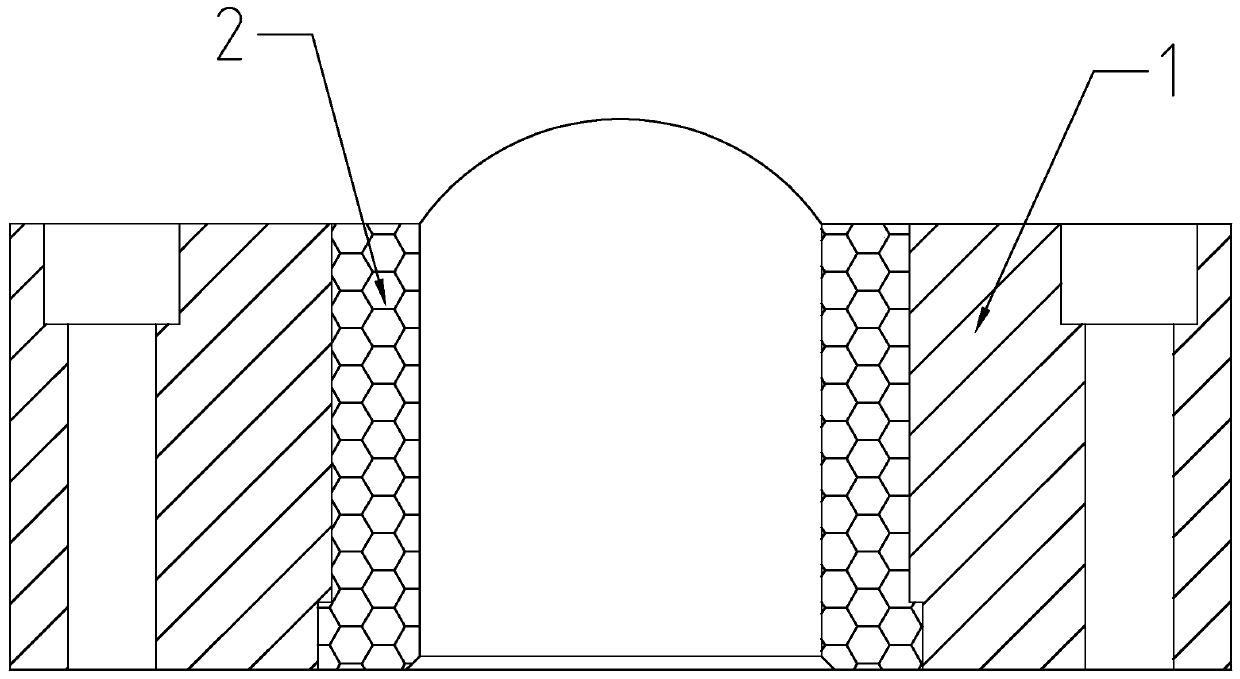

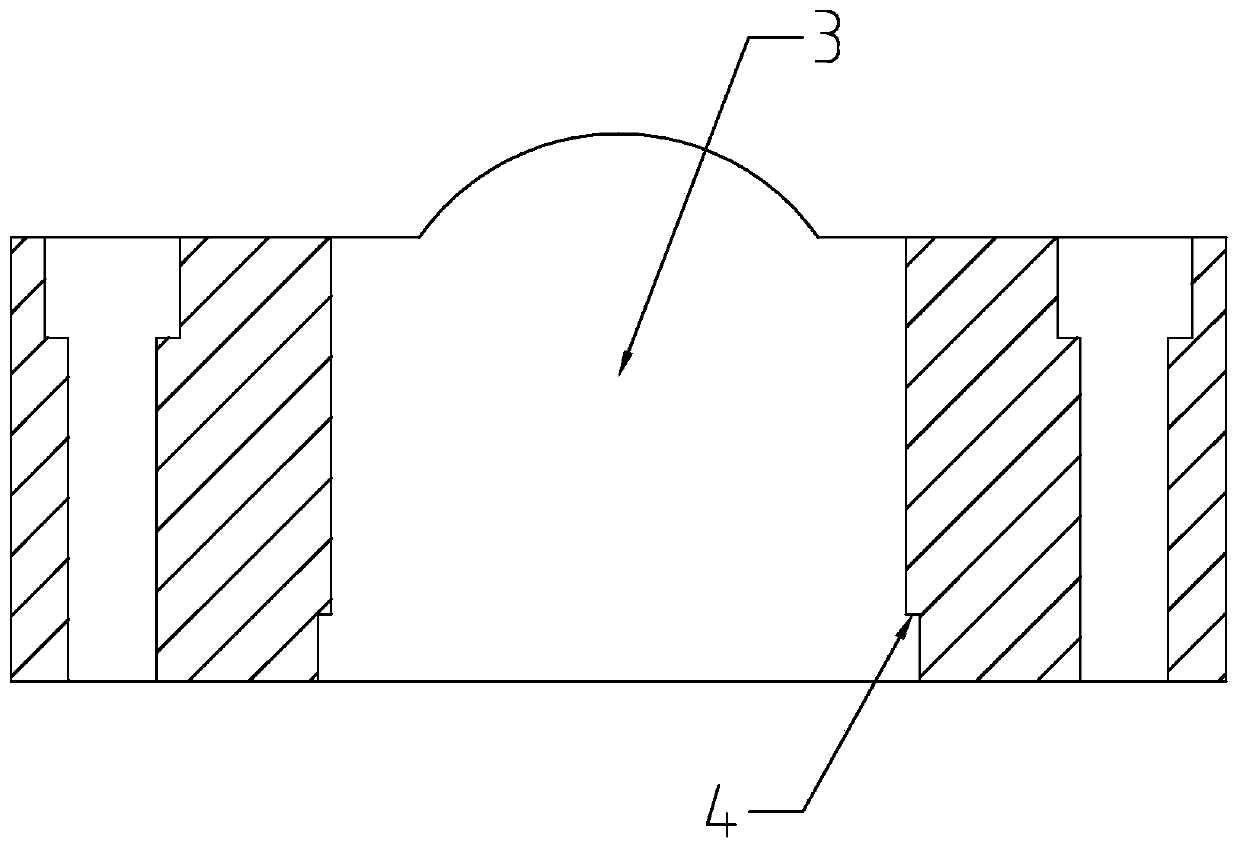

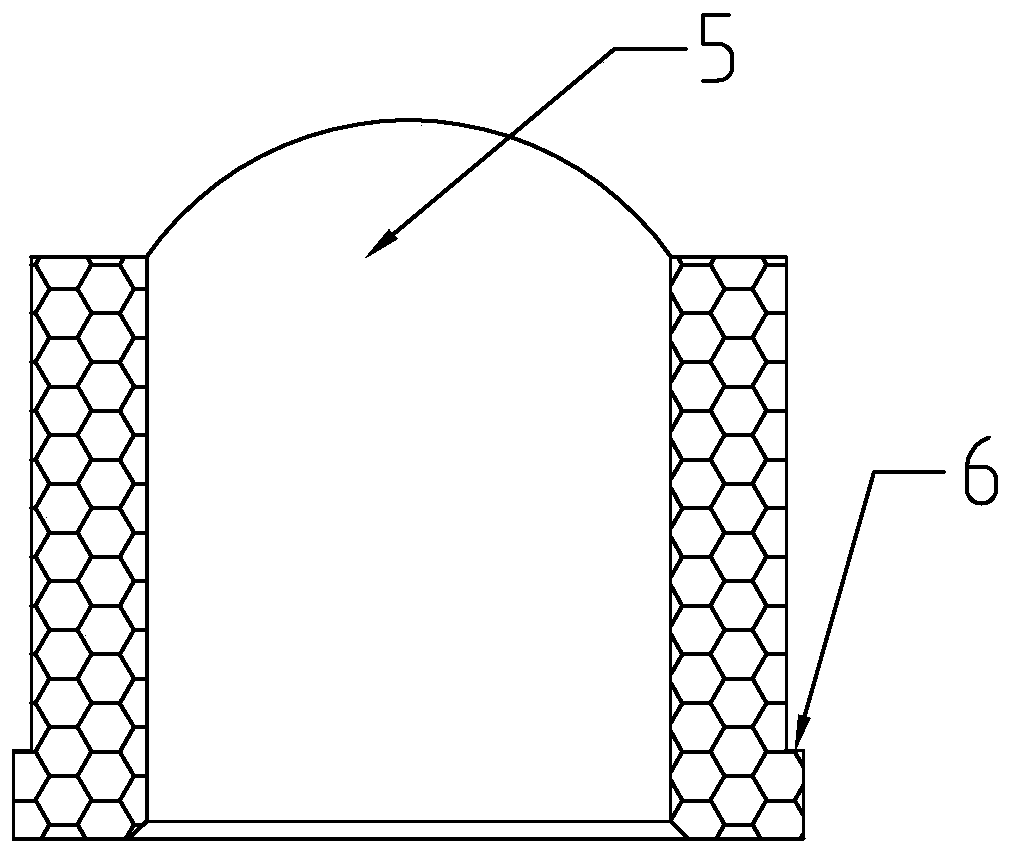

[0037] Such as Figure 1~4 Said, a permanent ferrite magnetic tile cemented carbide mold, which includes a die base 1 and an alloy cavity 2, a through hole 3 is opened in the middle of the die base, the through hole is a step hole, and the depth of the step 4 is 7mm , the large hole is 4mm larger than the small hole; the shape of the alloy cavity matches the through hole in the matrix of the die, a cavity 5 is provided in the middle of the alloy cavity, and a protrusion matching the step hole is provided outside the upper end of the alloy cavity 6. The size of the cavity is 0.02mm larger than the size of the step hole; the matrix of the die is made of non-magnetic stainless steel, and the alloy cavity is made of non-magnetic hard alloy.

[0038] A method for assembling a permanent ferrite magnetic tile cemented carbide mold, comprising the following steps:

[0039] a) Add water to the electric heating box and heat to 100°C;

[0040] b) Put the matrix of the die into the heat...

Embodiment 2

[0043] Such as Figure 1~4 Described, a kind of hard alloy mold of permanent magnet ferrite magnetic tile, it comprises die substrate 1 and alloy cavity 2, has a through hole 3 in the middle of die substrate, and through hole is step hole, and the depth of step 4 is 5mm , the large hole is 3mm larger than the small hole; the shape of the alloy cavity matches the through hole in the matrix of the die, a cavity 5 is provided in the middle of the alloy cavity, and a protrusion matching the step hole is provided outside the upper end of the alloy cavity 6. The size of the cavity is 0.01mm larger than the size of the step hole; the die base is made of non-magnetic stainless steel, and the alloy cavity is made of non-magnetic hard alloy.

[0044] A method for assembling a permanent ferrite magnetic tile cemented carbide mold, comprising the following steps:

[0045] a) Add assembly oil to the electric heating box and heat to 80°C;

[0046] b) Put the die matrix into the heated ass...

Embodiment 3

[0051] Such as Figure 1~4 Described, a kind of hard alloy mold of permanent magnet ferrite magnetic tile, it comprises die substrate 1 and alloy cavity 2, has a through hole 3 in the middle of die substrate, and through hole is a step hole, and the depth of step 4 is 6mm , the large hole is 4mm larger than the small hole; the shape of the alloy cavity matches the through hole in the matrix of the die, a cavity 5 is provided in the middle of the alloy cavity, and a protrusion matching the step hole is provided outside the upper end of the alloy cavity 6. The size of the cavity is 0.015mm larger than the size of the step hole; the die base is made of non-magnetic stainless steel, and the alloy cavity is made of non-magnetic hard alloy.

[0052] A method for assembling a permanent ferrite magnetic tile cemented carbide mold, comprising the following steps:

[0053] a) Add assembly oil to the electric heating box and heat to 110°C;

[0054] b) Put the die matrix into the heated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com