Honeycomb paperboard gluing method and device

A technology of honeycomb cardboard and cardboard, applied in the direction of cardboard items, etc., can solve the problems of production line speed drop, unevenness, affecting the quality of production, etc., and achieve the effect of improving speed and speed is stable and consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

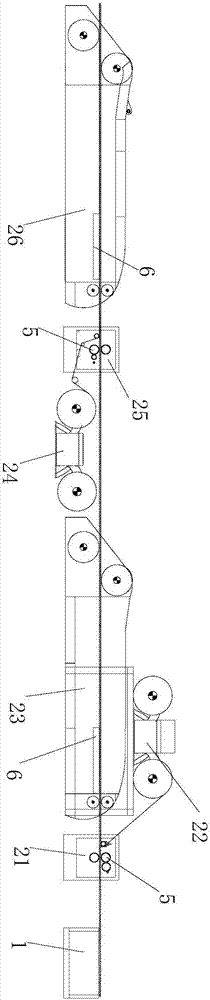

[0025] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

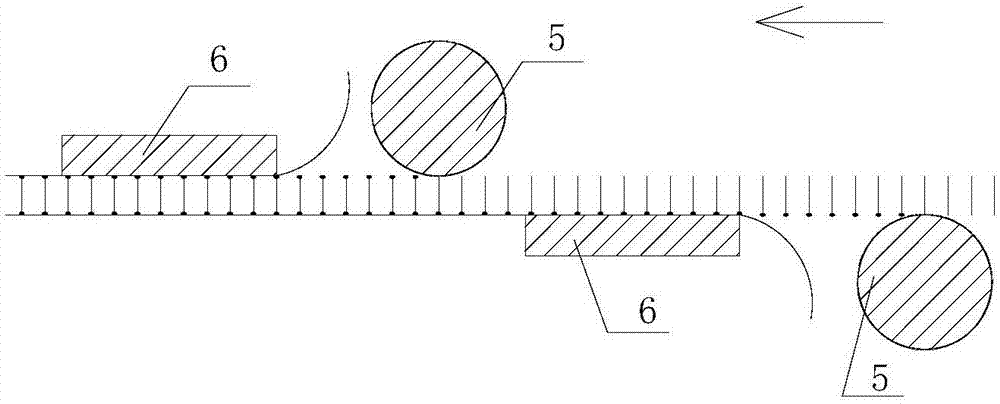

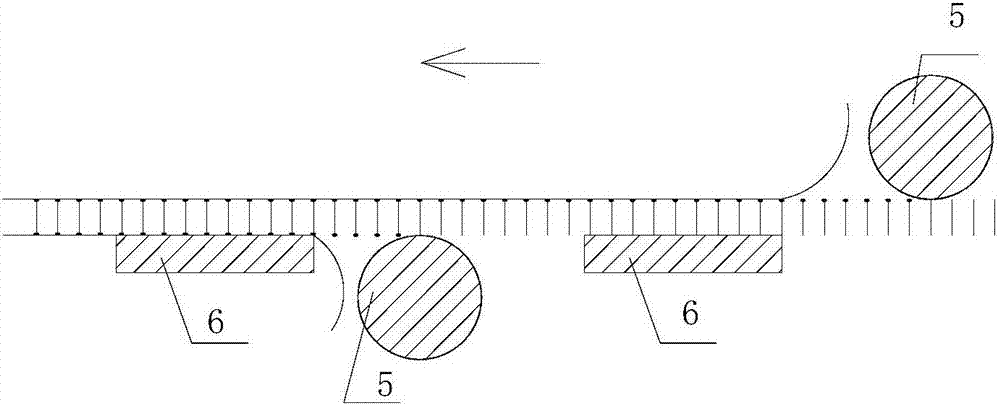

[0026] Such as figure 1 As shown, the present invention also provides a method for gluing the honeycomb paperboard, firstly gluing the upper layer of the core paper, and then gluing the lower layer.

[0027] The steps of the method are as follows:

[0028] Step 1, the honeycomb core paper is formed, and the honeycomb core paper is stretched by the core stretching machine 1;

[0029] Step 2, upper layer gluing, the core paper in step 1 is sent to the upper layer gluing machine for gluing, and a layer of base paper from the first base paper holder is fed above the core paper, and both are fed into the first double-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap