Solenoid valve, vehicle brake hyraulic pressure control apparatus and solenoid valve fabriation method

A solenoid valve and electromagnetic force technology, applied in the field of solenoid valves, can solve problems such as the decrease in productivity of solenoid valves, the instability of the upper end of spring components, and the difficulty in assembling the second valve seat component, so as to improve productivity, increase the degree of freedom, The effect of improving assemblability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

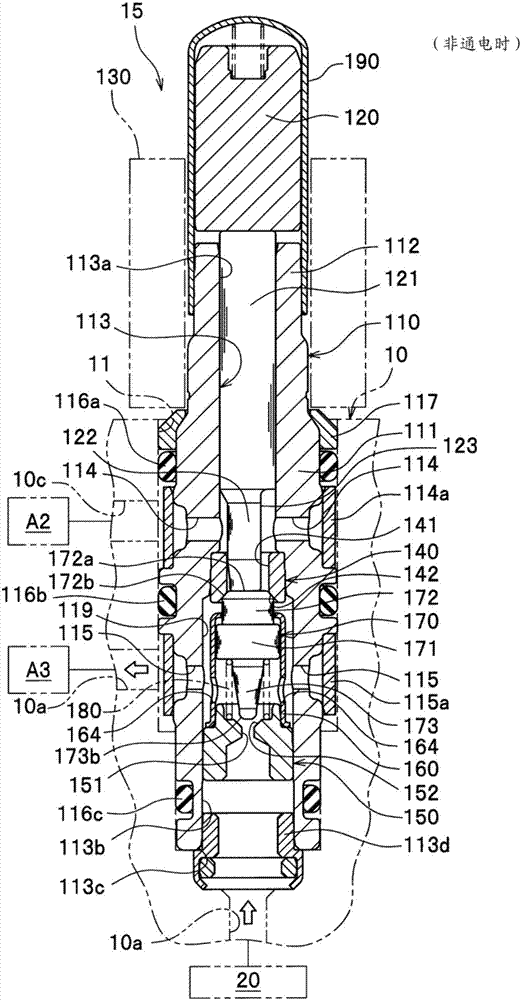

[0057] Embodiments of the present invention will be described in detail with reference to the drawings as appropriate.

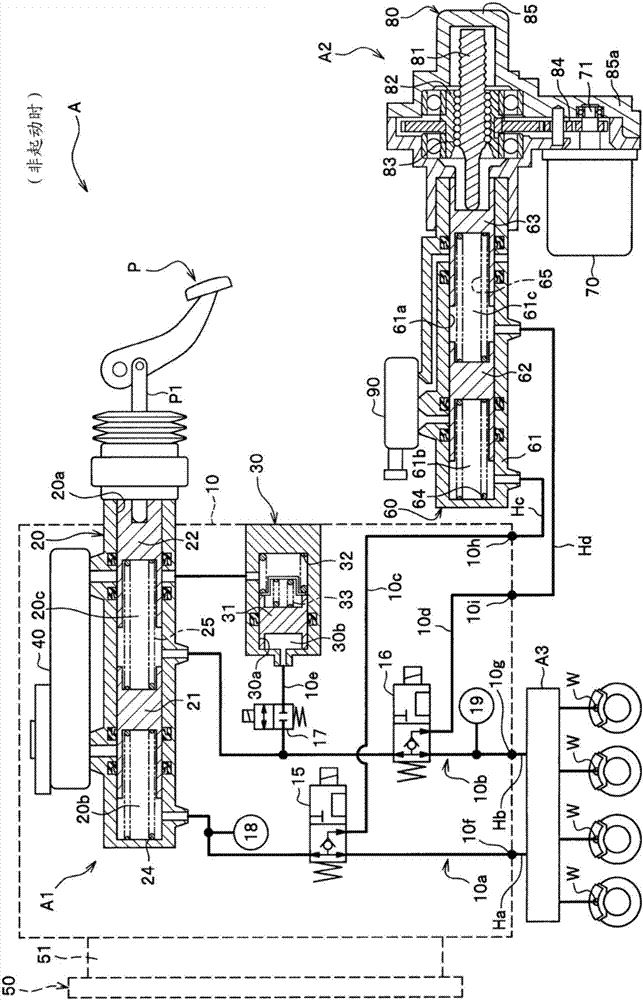

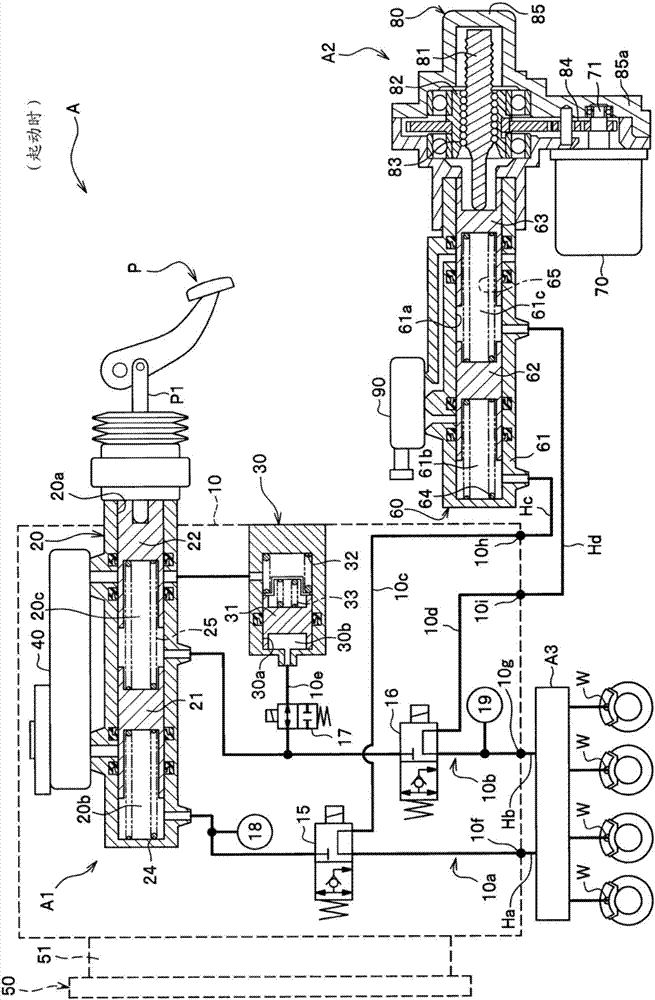

[0058] like figure 1 As shown, the vehicle brake fluid pressure control device A of this embodiment is provided with a By-Wire brake system that operates when the prime mover (engine or electric motor, etc.) A device that works on both hydraulic brake systems.

[0059] The vehicle brake fluid pressure control device A includes a brake fluid pressure generating device A1 that generates brake fluid pressure through the pedaling force of the brake pedal P (brake operating member), a motor cylinder device A2 that generates brake fluid pressure using the motor 70, and a vehicle behavior assisting device. Stabilized hydraulic controls A3.

[0060] The hydraulic pressure generating device A1, the motor cylinder device A2, and the hydraulic pressure control device A3 are constituted as other units and communicated through external piping.

[0061] The vehicle bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com