Endless rope continuous tractor double-rope horizontal hydraulic tensioning device

A technology of tensioning device and tractor, which is applied in the direction of fluid pressure actuation device, hoisting device, accumulator device, etc., can solve the problem of low volume and weight tensioning effect, large space occupied by hydraulic cylinder, installation and use Limits and other issues, to achieve the effect of simple structure, reducing the probability of broken wires and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

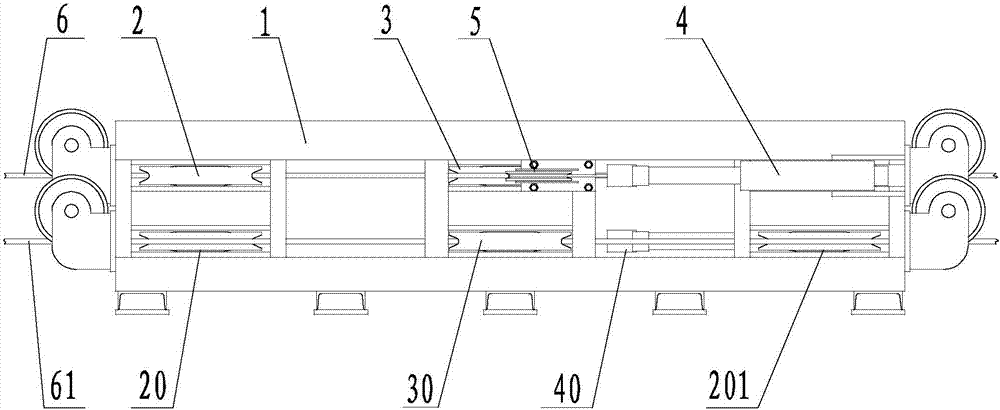

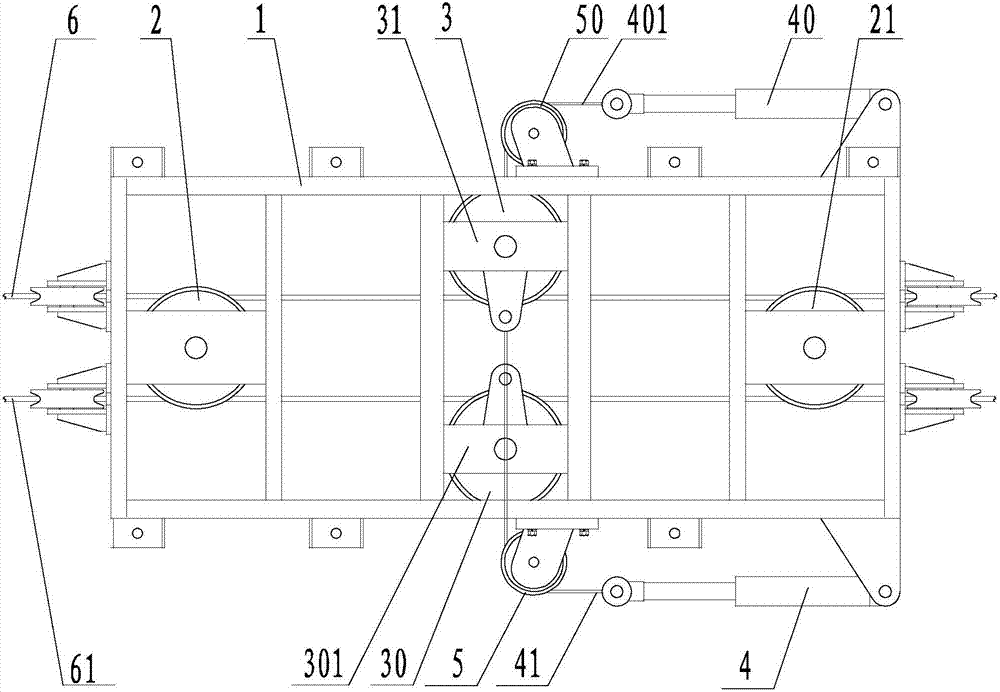

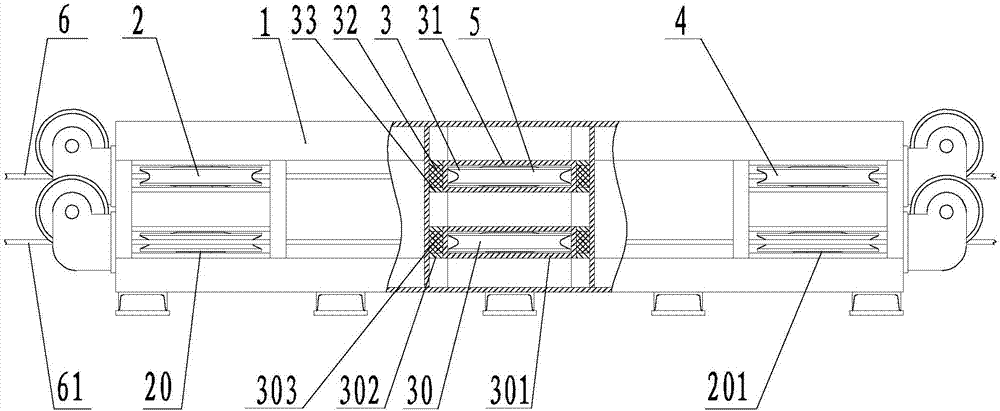

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a double-rope horizontal horizontal hydraulic tensioning device of a continuous rope tractor is installed at the rope outlet of the driving device 7 of the continuous rope tractor. The rope entry rope passes through the rope groove of the rope pulley 21 and the main rope tensioning wheel 3, and the traction shuttle car 8 runs after passing through, the main rope exit rope wraps around the rope pulley 2, and the main rope entry rope winding pulley 21 is located The main rope tensioning wheel 3 is located on the other side of the main rope 6; the auxiliary rope 61 goes out from the auxiliary rope and winds around the rope wheel 20, and the auxiliary rope enters the rope and winds the rope groove of the rope wheel 201 and the auxiliary rope tensioning wheel 30 Middle pass, auxiliary output rope winding wheel 2, auxiliary input rope winding wheel 21 is located at the same side of auxi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap