Modular sewage treatment device

A sewage treatment, modular technology, applied in biological treatment devices, biological water/sewage treatment, water/sludge/sewage treatment, etc. The effect of economical operation, guaranteed processing demand, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

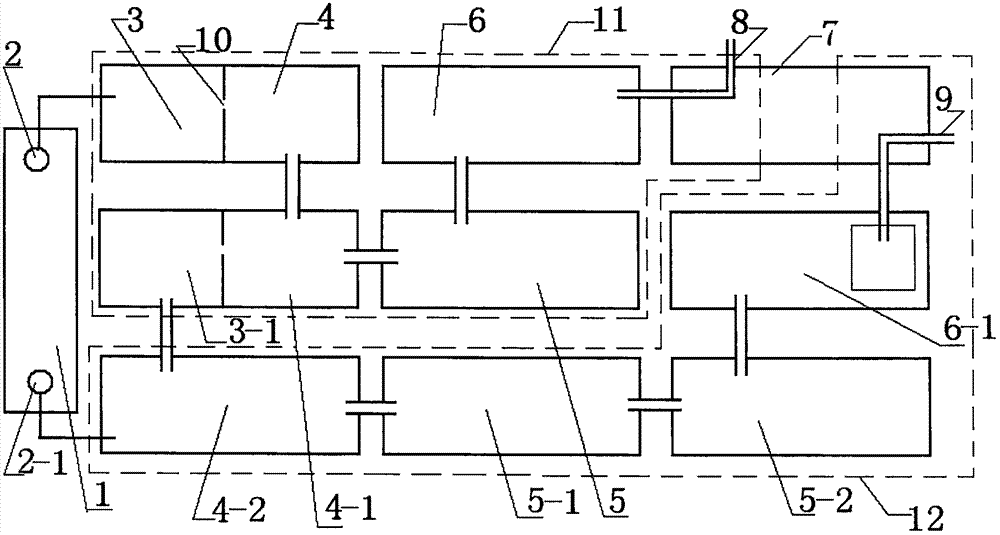

Image

Examples

Embodiment

[0023] Taking 1000 tons of equipment as an example, according to the actual usage, the daily processing capacity is 500 to 600 tons most of the time. Therefore, the 1000 tons of equipment is divided into a parallel combination of 600 tons and 400 tons, and the combination layout is based on the size of the equipment And the site environment, to meet the performance and save the floor area.

[0024] When the treated water volume is less than or equal to 400 tons (lower than the high level of the liquid level controller A), the first module 11 operates: the lift pump 2 starts, and the sewage enters the anaerobic pool 3 of each treatment unit of the first module 11 through the water inlet pipe through the lift pump 2 , anoxic pool 4, aerobic pool 5, and MBR membrane pool 6 (the processing unit anaerobic pool 3, anoxic pool 4, aerobic pool 5, and MBR membrane pool 6 are set according to the process design according to the effluent water quality requirements), and finally by The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com