System and method of operation for extracting glass fiber and pyrolysis oil from fan blades

A glass fiber, fan blade technology, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve the problems of difficult degradation of thermosetting composite materials, waste of resources, etc. Resource processing, solving the harm to the environment, the effect of independent and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

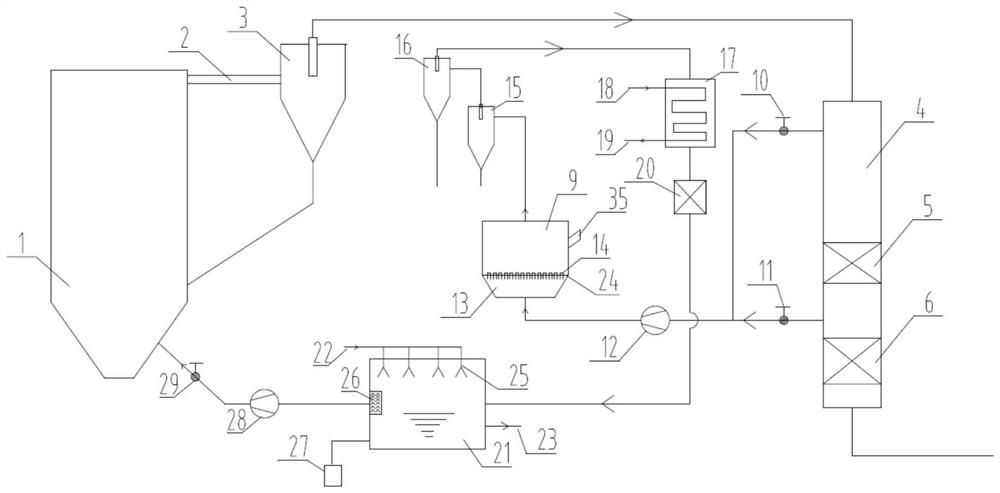

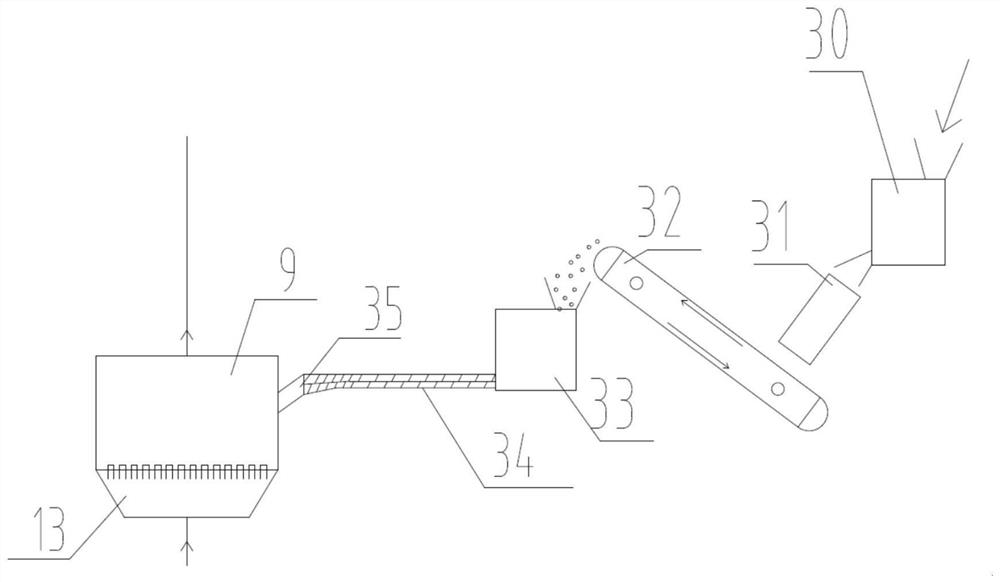

[0037] Such as figure 1 , the system for extracting glass fiber and pyrolysis oil from fan blades of the present invention mainly consists of 4 parts:

[0038] The first part is a conventional CFB boiler, including the furnace 1, the horizontal flue 2, the first cyclone separator 3, the tail flue 4, the economizer 5, the air preheater 6 and the figure 1 Other equipment and installations of CFB boilers not shown in , such as primary air / secondary air system, heating surface, dust collector and chimney, etc. These devices constitute a complete CFB boiler system, which can generate high-temperature and high-pressure steam for steam turbine power generation. As a conventional coal-fired power generation device, the operation of the blade pyrolysis recovery system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com