A kind of hot-melt elastomer modified asphalt waterproof membrane and its preparation method

A kind of asphalt waterproof membrane and modified asphalt technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of modified asphalt waterproof membranes such as poor thermal meltability, poor low-temperature flexibility, and water resistance that need to be improved. Improve the anti-destructive ability, improve the fusibility, and improve the effect of anti-destructive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

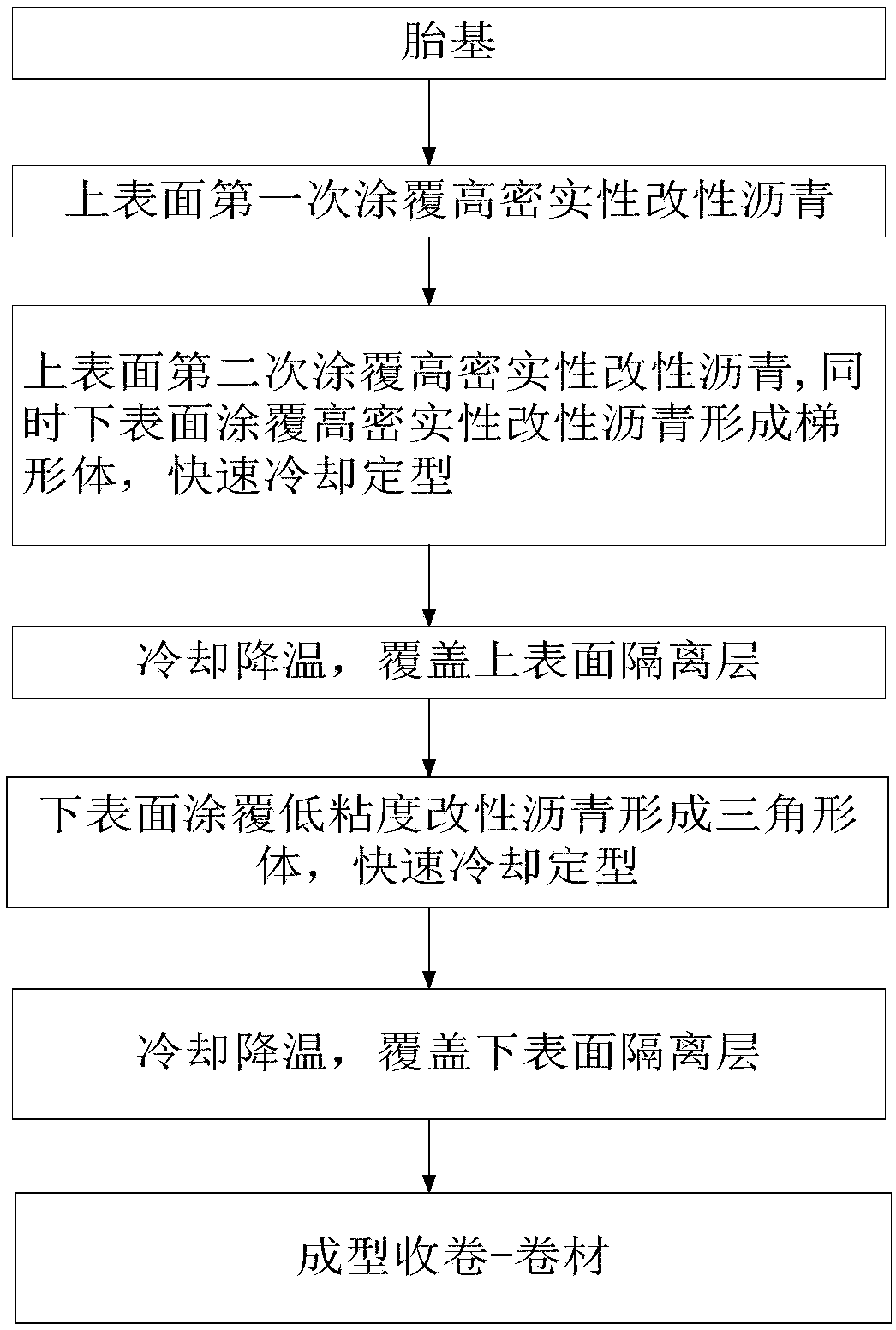

Method used

Image

Examples

Embodiment 1

[0042] Prepare the components of high-density modified asphalt according to the raw material formula: 90 parts of 90# asphalt, 40 parts of 200# asphalt, 22 parts of SBS (Yanhua 4402), 16 parts of organic bentonite, 3 parts of SBR, 3 parts of APAO, carbon black 3.4 parts, 38 parts of talcum powder, mix the above-mentioned asphalt, softener, SBS, modifier, thickener, defoamer and filler, heat to 180°C for shear blending, control stirring and blending for 5 hours to form a high-density Sexually modified asphalt;

[0043] Prepare low-viscosity modified asphalt components according to the raw material formula: 98 parts of 90# asphalt, 24 parts of second-line oil, 10 parts of SBS (Yanhua 1401), 12 parts of SBR, 10 parts of hydrogenated petroleum resin, Heilan viscosity reducer 5 parts of FHC, 34 parts of talcum powder, mix the above-mentioned asphalt, softener, SBS, modifier, viscosity reducer and filler and heat to 180°C, stir and blend for 5 hours to form low-viscosity modified as...

Embodiment 2

[0048] Prepare the components of high-density modified asphalt according to the raw material formula: 77 parts of 90# asphalt, 50 parts of 200# asphalt, 3 parts of third-line engine oil, 23 parts of SBS (Yanhua 4402), 13 parts of organic bentonite, 3 parts of SBR, 3 parts of APAO, 1.3 parts of carbon black, 40 parts of talcum powder, mix the above-mentioned asphalt, softener, SBS, modifier, thickener, defoamer and filler and heat to 180°C for shear blending, controlled stirring and blending After mixing for 5.5 hours, high-density modified asphalt is formed;

[0049] Prepare the components of low-viscosity modified asphalt according to the raw material formula: 70 parts of 90# asphalt, 40 parts of 200# asphalt, 12 parts of second line oil, 10 parts of SBS (Yanhua 1401), 12 parts of SBR, 10 parts of hydrogenated petroleum resin , Heilan viscosity reducer FHC 5 parts, talc powder 34 parts, mix the above-mentioned asphalt, softener, SBS, modifier, viscosity reducer and filler and...

Embodiment 3

[0055] Prepare the components of high-density modified asphalt according to the raw material formula: 114 parts of 90# asphalt, 20 parts of 200# asphalt, 6 parts of third line oil, 22 parts of SBS (Yanhua 4402), 16 parts of organic bentonite, 2.5 parts of SBR, 4 parts of APAO, 3.4 parts of carbon black, 40 parts of talcum powder, mix the above-mentioned asphalt, softener, SBS, modifier, thickener, defoamer and filler and heat to 180 ° C for shear blending, controlled stirring and blending After mixing for 5.5 hours, high-density modified asphalt is formed;

[0056] Prepare the components of low-viscosity modified asphalt according to the raw material formula: 84 parts of 90# asphalt, 20 parts of 200# asphalt, 18 parts of second-line oil, 10 parts of SBS (Yanhua 1401), 10 parts of SBR, 13 parts of hydrogenated petroleum resin , Heilan Viscosity Reducer FHC 5 parts, talc powder 38 parts, the above-mentioned asphalt, softener, SBS, modifier, viscosity reducer and filler are mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com