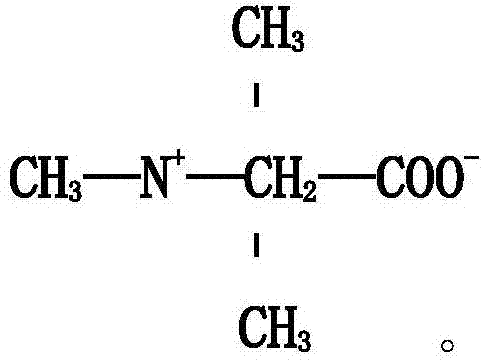

Application of betaine in preparation of alcoholic beverage and preparation method of alcoholic beverage

A technology of alcoholic beverages and betaine, which is applied in the preparation of alcoholic beverages, wine preparations, beer fermentation methods, etc., to achieve the effects of safe use, accelerated bacterial sedimentation, and no toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

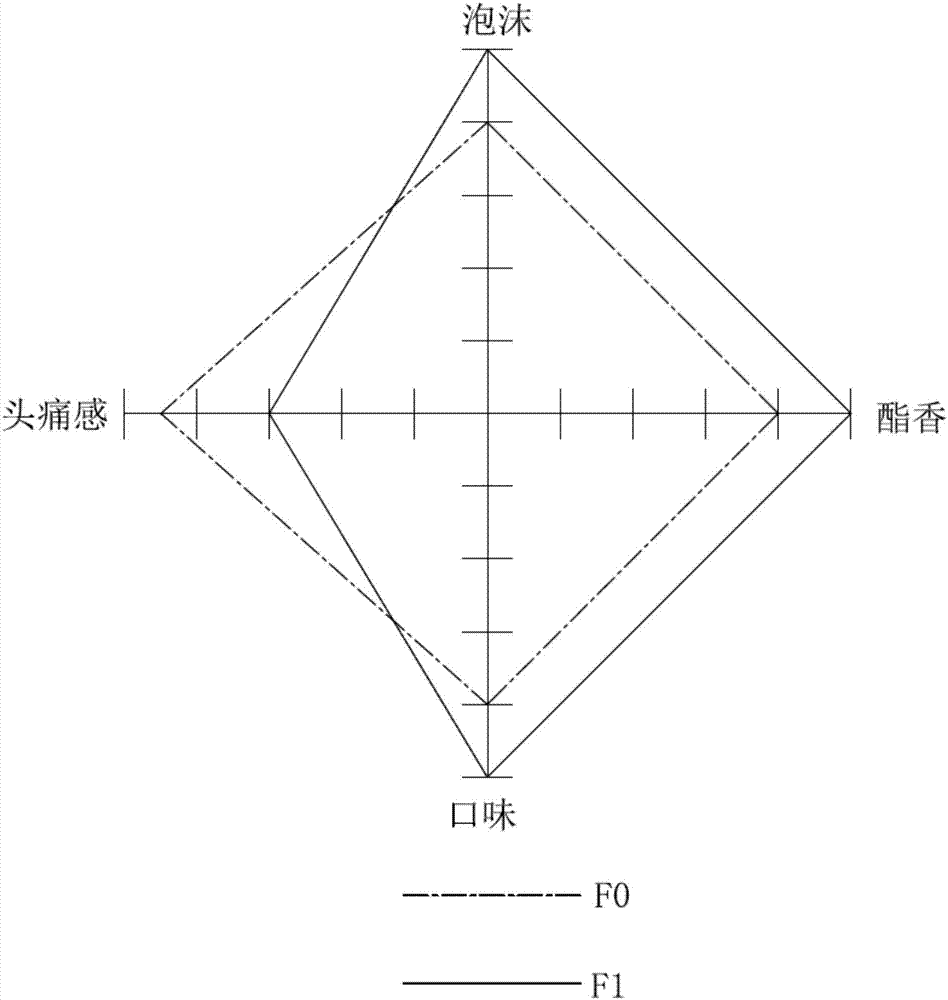

[0051] Adopt 4 200L beer fermentation tanks (Jinan Zhongde Beer Equipment Co., Ltd.) to carry out fermentation, respectively marked as F0, F1, F2, F3. The above fermentation method (full tank) is adopted, and the production process is carried out according to the production process steps of ordinary beer, that is, the production raw materials are saccharified, wort filtered, boiled, added hops, precipitated, cooled, fermented, and filtered to obtain beer.

[0052] Crush: Grind barley malt and wheat malt with a double-roller grinder (GD-5, Shandong Taian Light Industry Machinery Co., Ltd.), properly adjust the distance between the rollers, and require the wheat skin to be broken but not broken, and the endosperm to be broken as much as possible.

[0053] Saccharification: ensure that the ratio of material to water is 1:3.5.

[0054] The feeding temperature is 45°C, and the temperature is kept for 20 minutes;

[0055] Heat up to 50°C and keep warm for 40min;

[0056] Raise the...

Embodiment 2

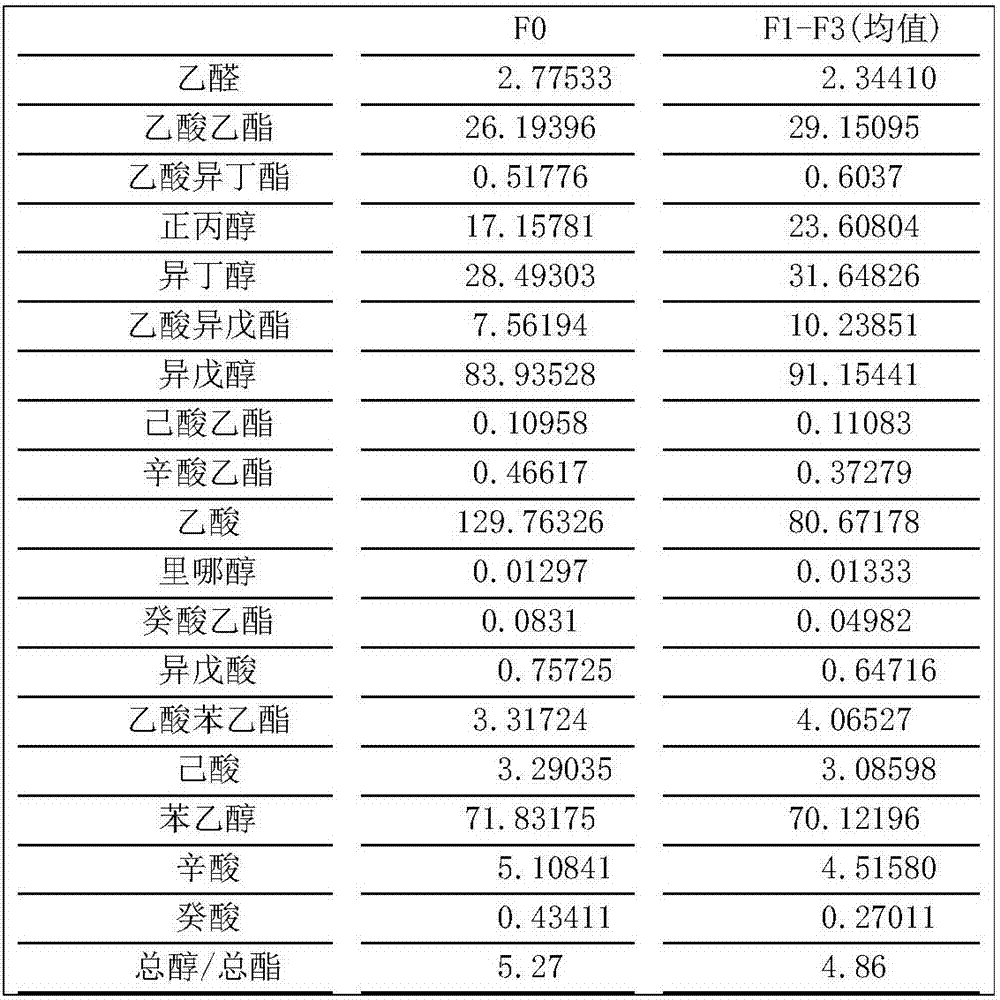

[0096] Fermentation was carried out in four 200L beer fermentation tanks according to the method steps of Example 1, wherein, F0 was the control without adding betaine, and F1, F2, and F3 were respectively added with 0.0046mol of the final effective fermentation volume in the cooling stage of the wort / l, 0.0093mol / l, 0.0140mol / l phosphobetaine (purchased from Shandong Xiangweisi Biotechnology Co., Ltd., purity 98%). The test was carried out in 3 batches, and the average value was taken.

[0097] Using the same detection method, the test results were obtained: From the taste point of view, the beer with betaine added had a softer taste, more harmonious aroma, and significantly lower alcohol-ester ratio than the control F0 without betaine added.

[0098]

Embodiment 3

[0100] Fermentation was carried out in four 200L beer fermenters according to the method steps of Example 1, wherein, F0 was the control without adding betaine, and F1, F2, and F3 were added respectively during the period from the beginning of fermentation to the 72h of fermentation, and the final effective 0.0065 mol / l, 0.0130 mol / l, and 0.0195 mol / l betaine hydrochloride (purchased from Shandong Xiangweisi Biotechnology Co., Ltd., purity 98%) were fermented. The test was carried out in 3 batches, and the average value was taken.

[0101] Using the same detection method, the test results were obtained: From the taste point of view, the beer with betaine added had a softer taste, more harmonious aroma, and significantly lower alcohol-ester ratio than the control F0 without betaine added.

[0102]

[0103]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com