Drag-reduction guiding unloading device and pushing method for pushing and constructing combined bridge

An unloading device and jacking technology, which is used in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult to remove friction reducing gaskets, large sliding friction, and difficult lateral offset constraints, so as to reduce personnel and The effect of auxiliary equipment configuration, reducing construction cost and convenient dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

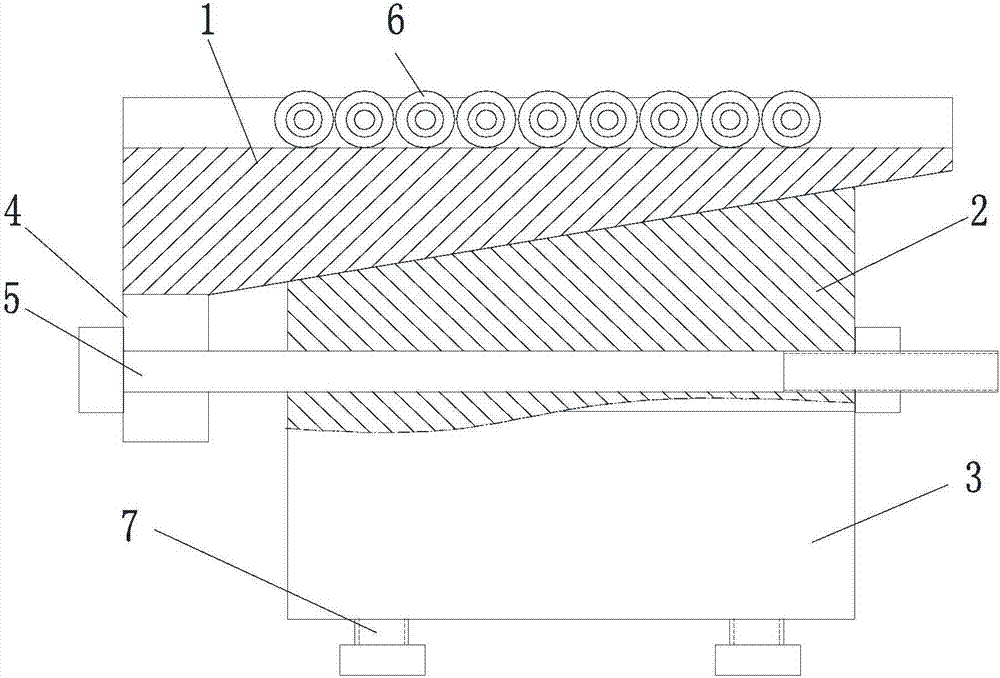

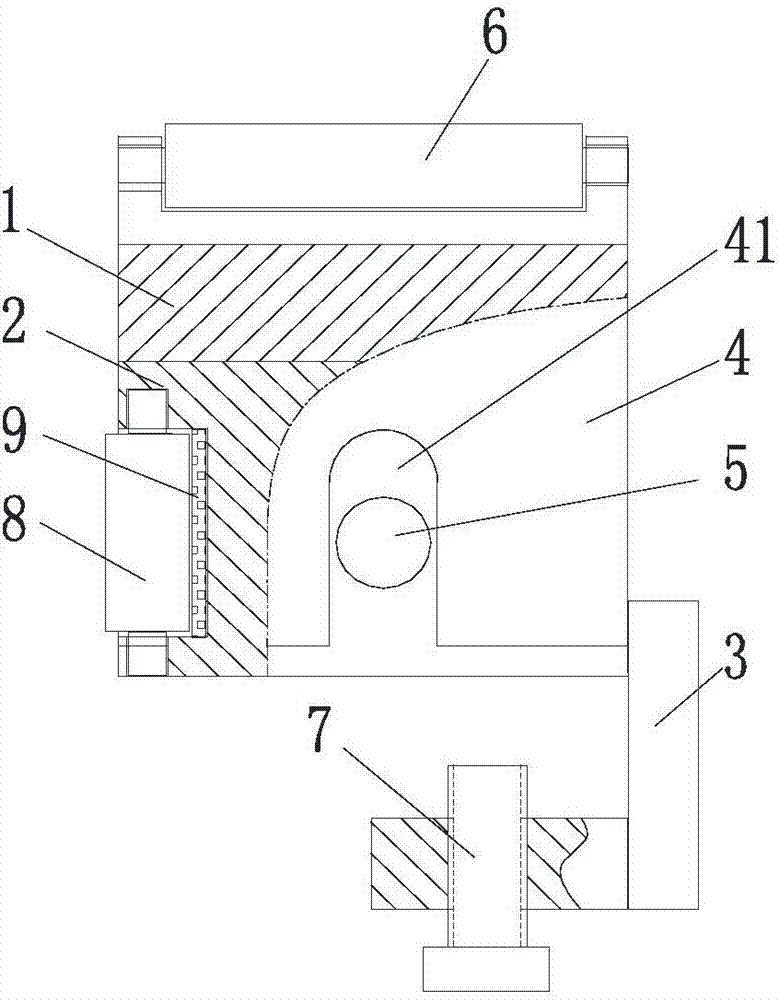

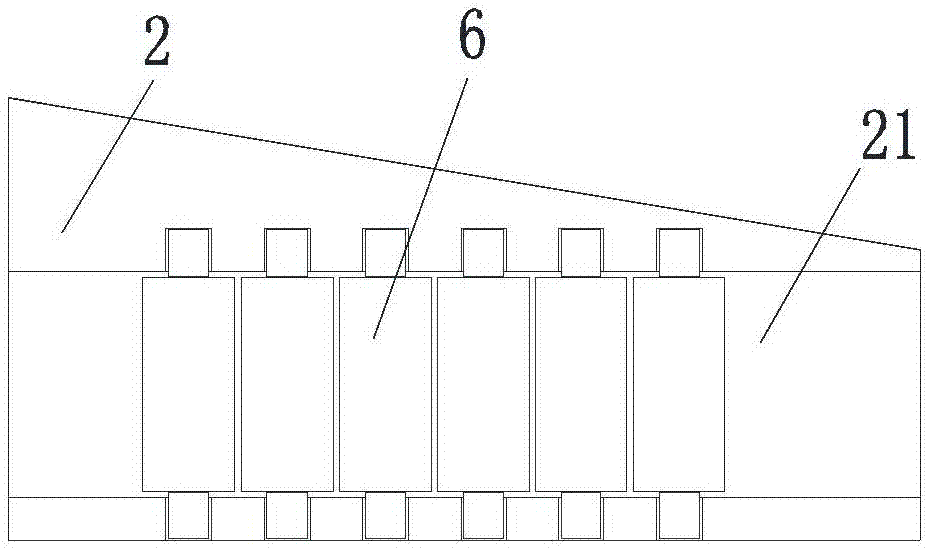

[0028] figure 1 is a schematic diagram of the longitudinal partial cross-sectional structure of the guide device, figure 2 It is a schematic diagram of the lateral partial cross-sectional structure of the guide device, image 3 Schematic diagram of the structure of the lower wedge, Figure 4 A longitudinal schematic diagram of the application structure for the guide, Figure 5 It is a horizontal schematic diagram of the application structure of the guide device. The drag reduction guide unloading device for pushing and constructing a composite bridge in this embodiment includes a lower support assembly and an upper sliding support, and the upper sliding support is arranged in a height-adjustable manner. The lower support assembly, the lower support assembly is fixed to the steel beam 13 of the bridge when in use, and the side of the drag reduction guide unloading device opposite to the side elevation of the rib 11 of the concrete bridge slab is provided with a guide surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com