Prestressed Safety Completion String and Method for the Whole Hole Section of Thermal Recovery Horizontal Well

A completion pipe string and prestressing technology, applied in wellbore/well components, drill pipe, casing, etc., can solve the problems of no effective compensation in the horizontal section and inability to pull prestressing, etc. The effect of well quality and strong righting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

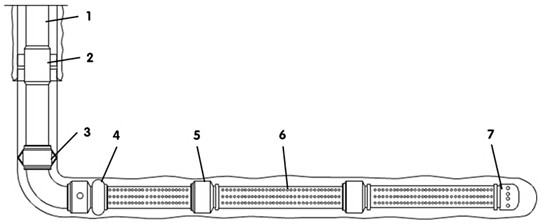

[0020] Example 1, xx horizontal well is completed with 7in casing + sand filter pipe, the well depth is 1500m, and the vertical section is 800m deep. The compensator 5 is respectively installed between the casing 1 and the sand filter pipe 6, and the well flushing valve 7 is installed at the rearmost end of the entire well completion string. Run the completion string into the well, pressurize 10MPa and set the hydraulic centralizer 3, and the upper arm of the centralizer is supported on the open hole wall to ensure that the casing is centered in the well. Press 12MPa to open the anchor fluke of the hollow prestressed ground anchor 2. The anchor fluke is supported on the open hole wall, and the lifting pipe string is used to lift the prestress to 40 tons, and then continue to press to 14MPa to seal the plug-free grading hoop 4 rubber tube. Afterwards, pressurize to 16MPa to open the drill-free grading collar 4 circulation channel, and perform cement injection and cementing to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com