Blade blowing machine with lithium battery drive motor circumferential parallel filtering noise elimination air pipes

A technology for driving motors and lithium batteries, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc. It can solve the problems of restricting high-speed and strong wind, not conforming to light and small output, and consuming motor output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0199] The operation walker selects the leaf blowing and sucking machine according to liking and habit, preferably wears protective glasses and a mask, and also uses shoulder strap 43 to be set on the shoulder and on the casing; pull out the telescopic tube of blowing and sucking, adjust the rotating speed, adjust Auxiliary handle; check the power supply, connect enough long power cords, check the insurance again, follow the instruction manual, try to open it, check that there are no broken glass and wires in the area with leaves, and use the leaf blower to do it under safe conditions, and at the same time Pay attention to the weather and rain.

[0200] The specific implementation mode that the present invention takes to solve its technical problem is explained in detail again below:

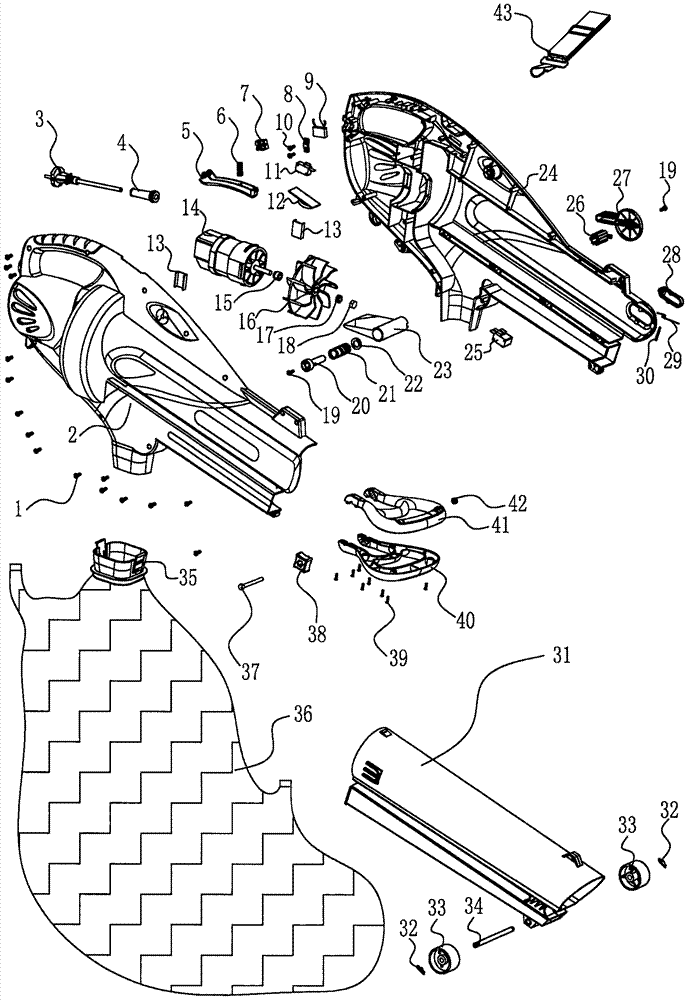

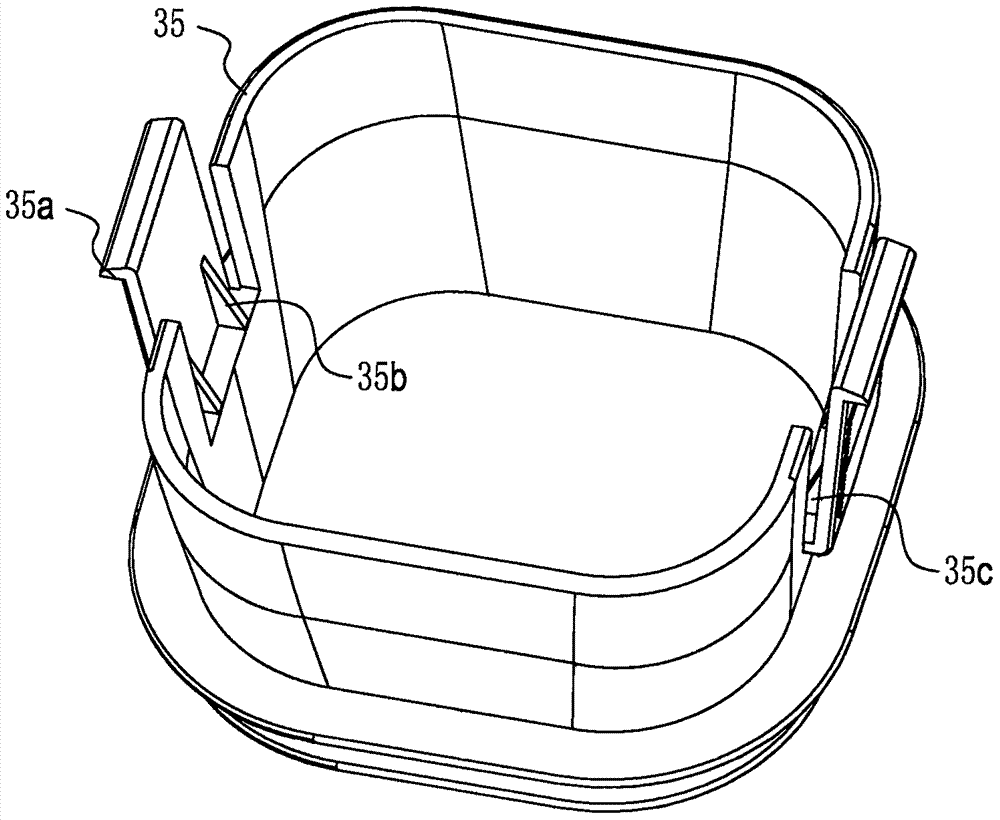

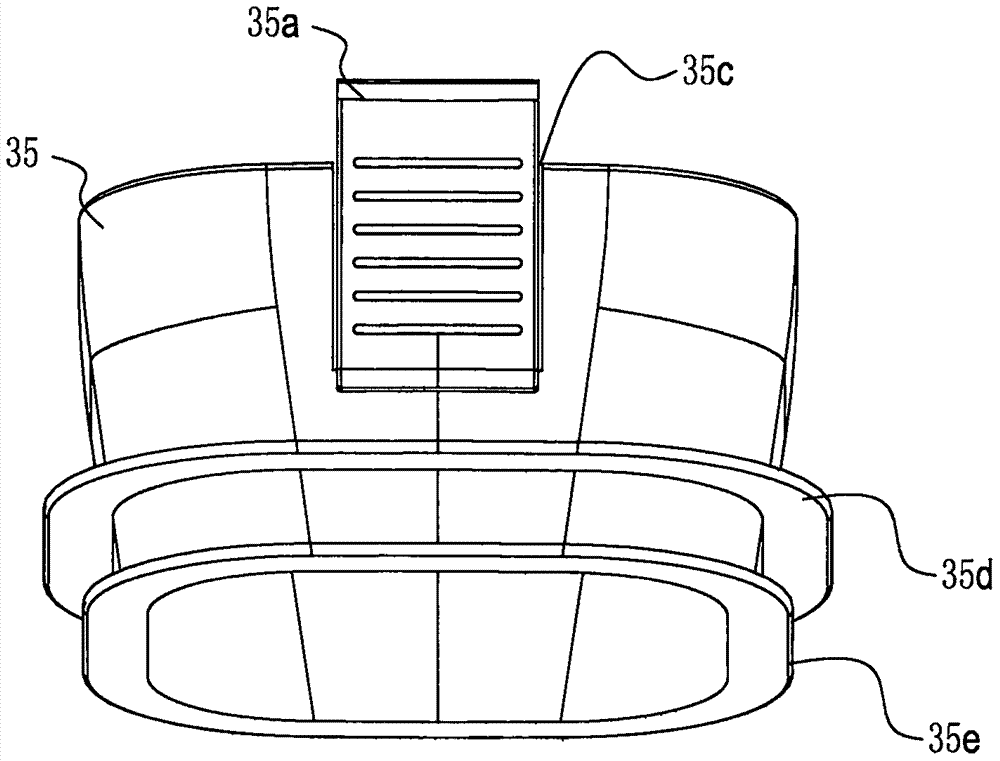

[0201]Because of the improvement of a low-vibration leaf blowing machine, including the addition of a movable auxiliary handle, the improvement of the dust bag bracket and the opening, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com