Intelligent flexible production line and production method thereof

A flexible production line and flexible production technology, applied in the direction of comprehensive factory control, instruments, and comprehensive factory control, can solve the problems of insufficient flexibility, large line change time, and large workload, and achieve the goal of improving production efficiency and automation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

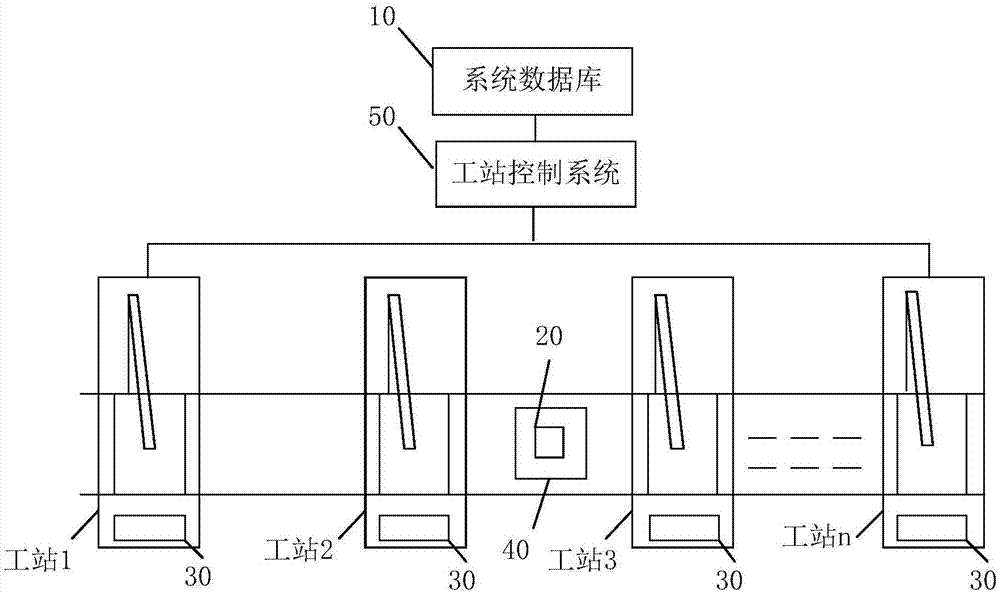

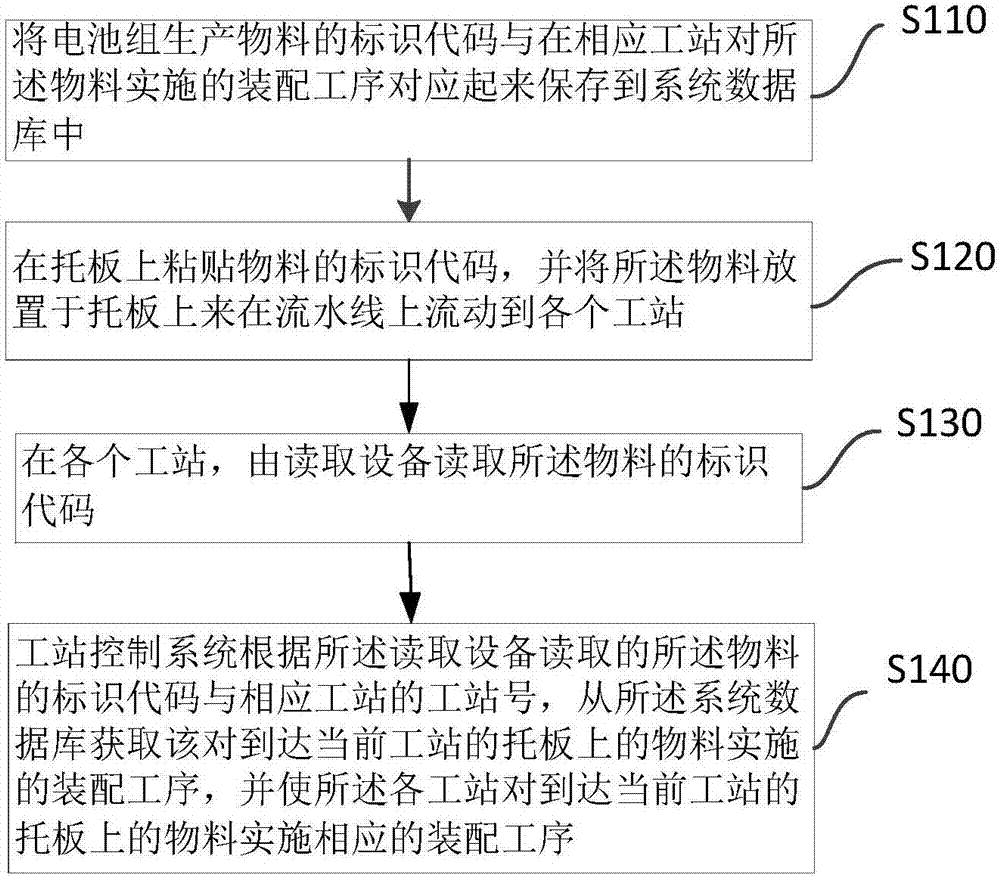

[0017] In the following, the preferred embodiments of the present invention will be described in detail by taking the intelligent flexible production line of automobile power battery packs as an example with reference to the accompanying drawings.

[0018] The so-called catering system ingredients work mode adopts the pallet structure, that is, the materials required for the current product are placed on the pallet in a stacked manner with the small tray as the carrier. The pallet flows on the assembly line. When it arrives at the station, the industrial camera reads the barcode of the pallet and uploads it together with the current station to the MES system (manufacturing system) database for query, so as to obtain the information of the product at the current station. The specific process flow that needs to be completed. The station control system performs corresponding actions according to the downloaded process flow, obtains materials from the designated small pallets to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com