Flat wire harness for electrical connection in automobiles

A technology of electrical connection and flat wire, which is applied in the field of flat wire harness for electrical connection in new energy vehicles, can solve the problems of complex wiring and high installation cost, and achieve the effects of simplified wiring, convenient and safe assembly or maintenance, and improved wiring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

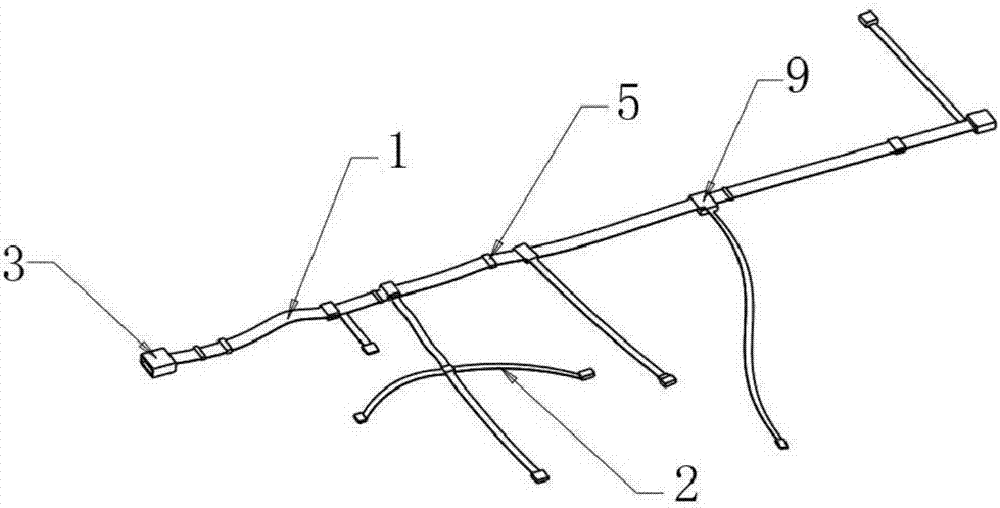

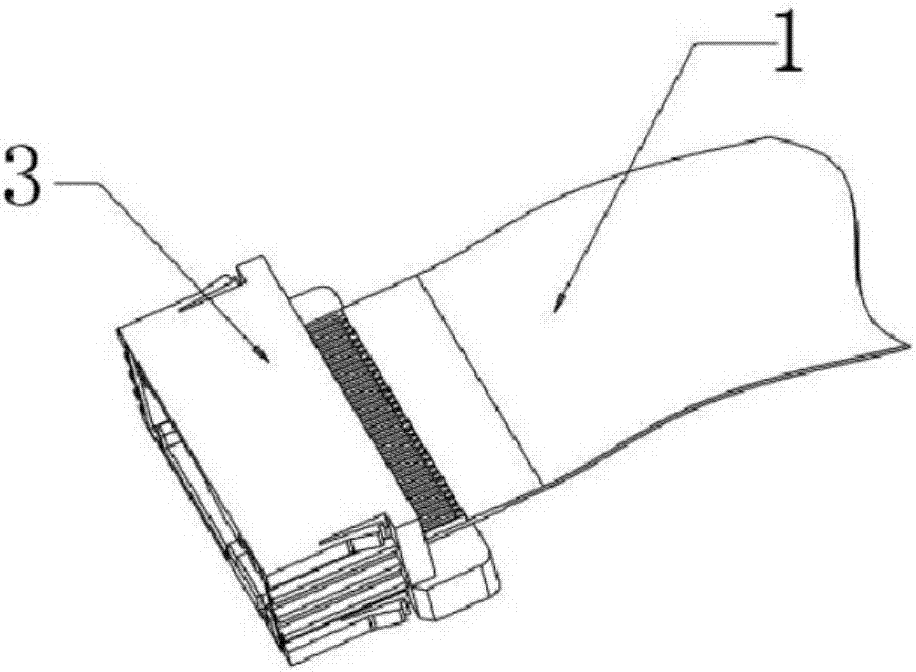

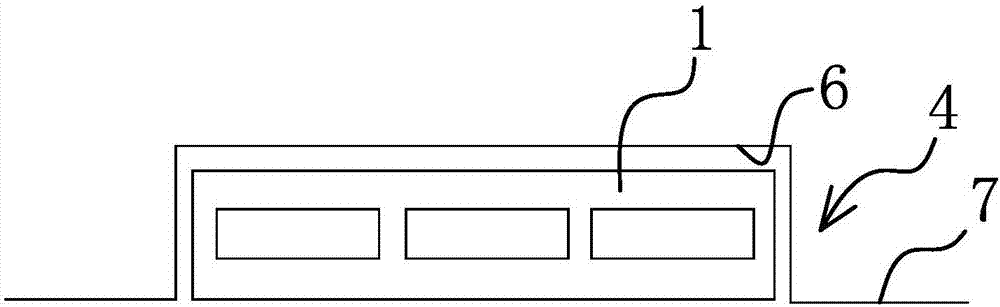

[0024] Such as Figure 1-5 As shown, the flat wire harness for connecting electrical appliances in the automobile includes a flat main line 1 cut from ffc flexible cable, and the flat main line 1 has a number of flat branches formed by extending to the outside of the flat main line 1 in the form of branches. The branch line 2 and the flat branch line 2 are also intercepted from the ffc flexible cable. The ffc flexible cable is a flexible flat cable, which is composed of multiple copper conductors arranged in parallel with each other and synthesized by a reinforcing plate. Layers of PET film with adhesive backing finally form the ffc flexible cable. The ffc flexible flat cable can be used to select the number and spacing of wires arbitrarily, which makes the connection more convenient, greatly reduces the volume of electronic products...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com