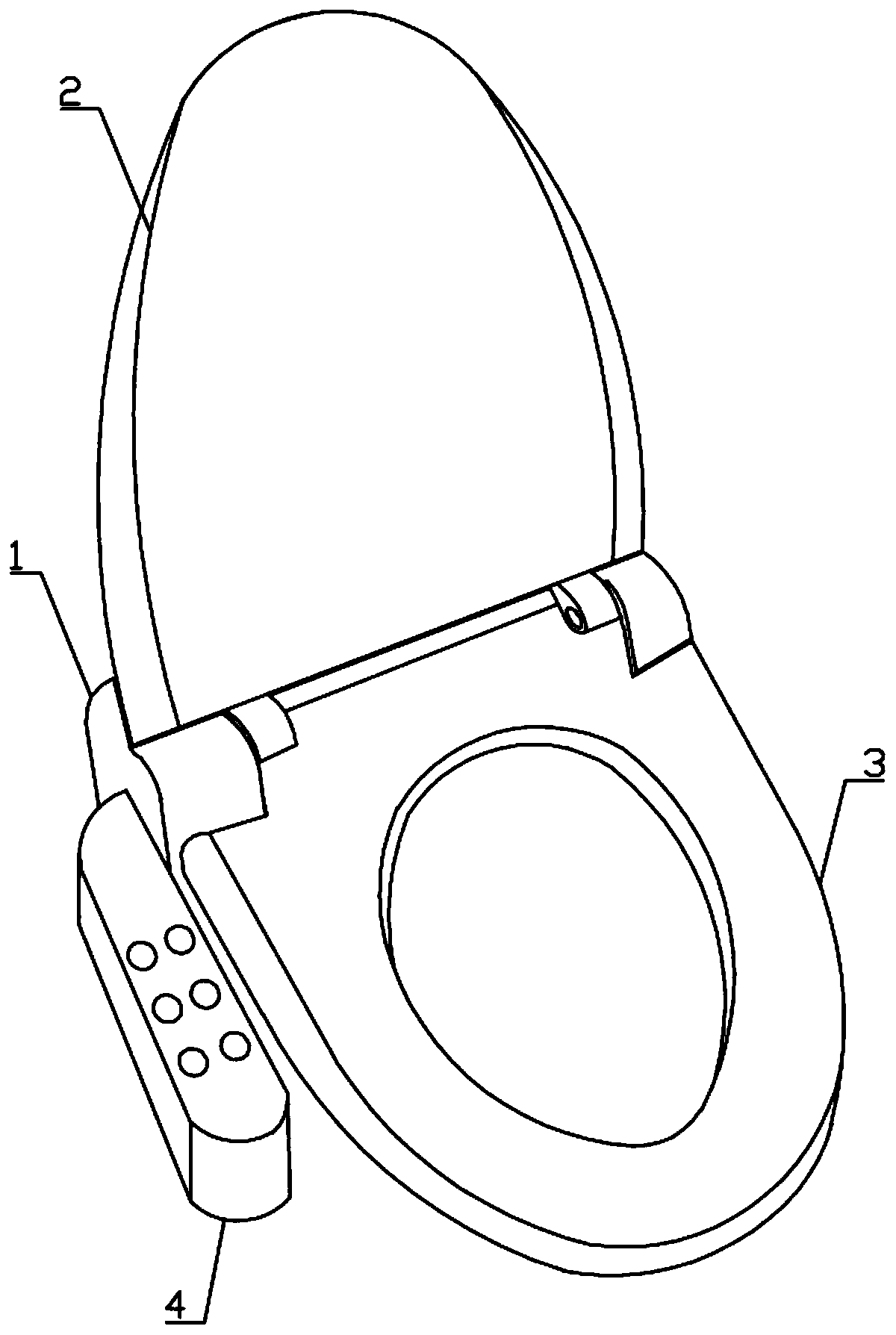

A toilet lid with a seat washer with continuous sterilization function

A technology for toilet lids and gaskets, which is applied to toilet seats or covers, treatment, radiation therapy, etc., can solve the problems of low utilization rate of artificial disinfection and disinfectant, cumbersome operation procedures, and incomplete disinfection, etc., to promote and improve blood circulation. Circulation, simple operation process, comprehensive and thorough sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the three dan oil microcapsules for filling in the present invention is as follows: the preparation method of the three dan oil microcapsules is as follows: get the three dan oil stock solution and pour it into a container, then add 10 times the volume of ethanol, fully stir and dilute, and obtain three dan oil microcapsules. Dandan oil dilution; take hydroxypropyl methylcellulose with 4.2 times the volume of sandan oil, dry it fully, then add it to the sandan oil dilution, stir and disperse fully to obtain a suspension; take sodium sulfate and add it while stirring In the suspension, after the addition is completed, continue to stir for 5-10 minutes to obtain the suspension of sandan oil microcapsules; depressurize the suspension of sandan oil microcapsules at 35°C-40°C and 0.09MPa-0.1MPa Ethanol is distilled off to obtain sandan oil microcapsules.

[0029] The nanometer far-infrared ceramic powder that filling of the present invention is used...

Embodiment 2

[0040] The preparation method of the sandan oil microcapsules used for filling in the present invention is as follows: get the sandan oil stock solution and pour it into a container, then add 10 times the volume of ethanol, fully stir and dilute to obtain the sandan oil dilution; take the sandan oil 4.2 times The volume of hydroxypropyl methylcellulose is fully dried, then added to the Sandan oil dilution, fully stirred and dispersed to obtain a suspension; add sodium sulfate to the suspension while stirring, and continue to stir for 5 ~ 10min to obtain the suspension of sandan oil microcapsules; distill the suspension of sandan oil microcapsules at 35°C to 40°C and 0.09 MPa to 0.1MPa to remove ethanol under reduced pressure to obtain sandan oil microcapsules .

[0041] The nanometer far-infrared ceramic powder that filling of the present invention is used is before adding deionized water, earlier carries out surface modification to nanometer far-infrared ceramic powder, and t...

Embodiment 3

[0052] The preparation method of the sandan oil microcapsules used for filling in the present invention is as follows: get the sandan oil stock solution and pour it into a container, then add 10 times the volume of ethanol, fully stir and dilute to obtain the sandan oil dilution; take the sandan oil 4.2 times The volume of hydroxypropyl methylcellulose is fully dried, then added to the Sandan oil dilution, fully stirred and dispersed to obtain a suspension; add sodium sulfate to the suspension while stirring, and continue to stir for 5 ~ 10min to obtain the suspension of sandan oil microcapsules; distill the suspension of sandan oil microcapsules at 35°C to 40°C and 0.09 MPa to 0.1MPa to remove ethanol under reduced pressure to obtain sandan oil microcapsules .

[0053] The nanometer far-infrared ceramic powder that filling of the present invention is used is before adding deionized water, earlier carries out surface modification to nanometer far-infrared ceramic powder, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com