Online extrusion production technology for 7A04 high-strength bar

A production process, 7A04 technology, applied in the field of 7A04 high-strength bar online extrusion production process, can solve the problems of slow extrusion speed, time-consuming, low daily output of high-strength bars, etc., and achieve the effect of improving frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

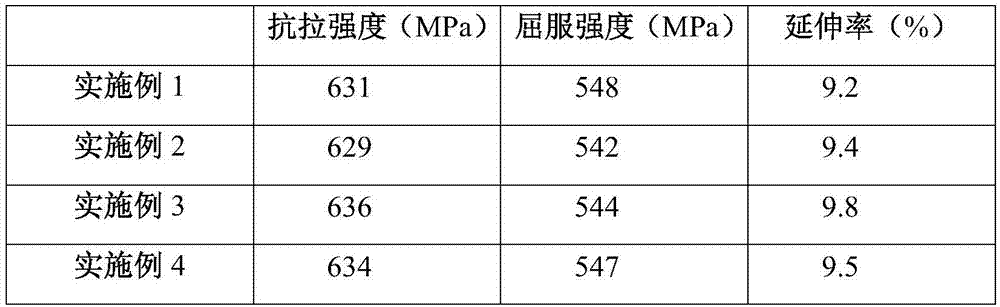

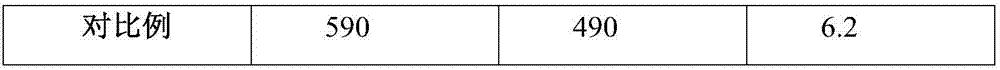

Examples

Embodiment 1

[0022] A 7A04 high-strength bar online extrusion production process, comprising the steps of:

[0023] A. Ingredients: The mass percentage ratio of each element in 7A04 aluminum alloy ingot is as follows:

[0024] element

Si

Fe

Cu

mn

Mg

Zn

Ti

Impurities

Al

content

0.50

0.50

2.0

0.6

2.8

7.0

0.1

0.15

margin

[0025] The 7A04 aluminum alloy ingot is pretreated. After the pretreated ingot is homogenized and annealed at 450°C for 8 hours, it is placed in the extrusion cylinder of the extruder, and the diameter of the 7A04 aluminum alloy ingot is 436mm;

[0026] B. Heat the product mold in the extrusion barrel to 520°C, control the temperature of the 7A04 aluminum alloy ingot to 420°C, and the outlet temperature of the extruder to 380°C, and clamp the workbench with the product mold and the extrusion barrel together, among which The working surface of the product mold is smeared with lubricating oil;...

Embodiment 2

[0031] A 7A04 high-strength bar online extrusion production process, comprising the steps of:

[0032] A. Ingredients: The mass percentage ratio of each element in 7A04 aluminum alloy ingot is as follows:

[0033] element

Si

Fe

Cu

mn

Mg

Zn

Ti

Impurities

Al

content

0.50

0.50

1.4

0.5

2.6

6.5

0.1

0.15

margin

[0034] The 7A04 aluminum alloy ingot is pretreated. After the pretreated ingot is homogenized and annealed at 450°C for 8 hours, it is placed in the extrusion cylinder of the extruder, and the diameter of the 7A04 aluminum alloy ingot is 358mm;

[0035] B. Heat the product mold in the extrusion barrel to 500°C, control the temperature of the 7A04 aluminum alloy ingot to 380°C, and the outlet temperature of the extruder to 400°C, and clamp the workbench with the product mold and the extrusion barrel together, among which The working surface of the product mold is smeared with lubricating oil;...

Embodiment 3

[0040] A 7A04 high-strength bar online extrusion production process, comprising the steps of:

[0041] A. Ingredients: The mass percentage ratio of each element in 7A04 aluminum alloy ingot is as follows:

[0042] element

Si

Fe

Cu

mn

Mg

Zn

Ti

Impurities

Al

content

0.50

0.50

1.8

0.55

2.7

6.9

0.1

0.15

margin

[0043] The 7A04 aluminum alloy ingot is pretreated. After the pretreated ingot is homogenized and annealed at 450°C for 8 hours, it is placed in the extrusion cylinder of the extruder, and the diameter of the 7A04 aluminum alloy ingot is 436mm;

[0044] B. Heat the product mold in the extrusion barrel to 520°C, control the temperature of the 7A04 aluminum alloy ingot to 420°C, and the outlet temperature of the extruder to 400°C, and clamp the workbench with the product mold and the extrusion barrel together. The working surface of the product mold is smeared with lubricating oil;

[0045] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com