Continuous casting soft press thickness measuring roller arranging and controlling method

A control method and light reduction technology, applied in the field of continuous casting and light reduction, can solve the problems of accurate measurement of slab thickness, deviation in process execution, inconsistent slab size, etc., to ensure stability, ensure stability, and control simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

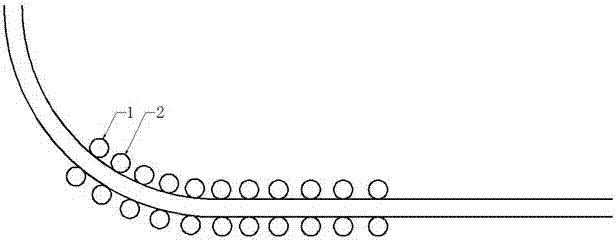

[0027] A continuous casting soft reduction thickness measuring roll and its control method in this embodiment, the thickness measuring roll includes a thickness measuring roll A and a thickness measuring roll B, and the arrangement method is to arrange the light reduction rolls respectively along the casting direction, Thickness measuring roll A is located at the forefront, thickness measuring roll B is set behind thickness measuring roll A, and subsequent light pressing is arranged behind thickness measuring roll B to execute each roll; the control method is: when the slab production reaches a steady state, the Thickness measuring roll A and thickness measuring roll B both adopt the pressure control mode, and a constant force of 200kN is applied to the upper roll, and the displacement sensor of thickness measuring roll A will collect the continuous casting slab thickness measurement values A1, A2, A3, A4... and data processing, more specifically, the processed value A and th...

Embodiment 2

[0029]A continuous casting soft reduction thickness measuring roll and its control method in this embodiment, the thickness measuring roll includes a thickness measuring roll A and a thickness measuring roll B, and the arrangement method is to arrange the light reduction rolls respectively along the casting direction, Thickness measuring roll A is located at the forefront, thickness measuring roll B is set behind thickness measuring roll A, and subsequent light pressing is arranged behind thickness measuring roll B to execute each roll; the control method is: when the slab production reaches a steady state, the Thickness measuring roll A and thickness measuring roll B both adopt the pressure control mode, and a constant force of 300kN is applied to the upper roll, and the displacement sensor of thickness measuring roll A will collect the continuous casting slab thickness measurement values A1, A2, A3, A4... and data processing, more specifically, the processed value A and the...

Embodiment 3

[0031] A continuous casting soft reduction thickness measuring roll and its control method in this embodiment, the thickness measuring roll includes a thickness measuring roll A and a thickness measuring roll B, and the arrangement method is to arrange the light reduction rolls respectively along the casting direction, Thickness measuring roll A is located at the forefront, thickness measuring roll B is set behind thickness measuring roll A, and subsequent light pressing is arranged behind thickness measuring roll B to execute each roll; the control method is: when the slab production reaches a steady state, the Thickness measuring roll A and thickness measuring roll B both adopt the pressure control mode, and a constant force of 250kN is applied to the upper roll, and the displacement sensor of thickness measuring roll A will collect the continuous casting slab thickness measurement values A1, A2, A3, A4... and data processing, more specifically, the processed value A and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com