Measuring and calibrating device for laser processing focal length and incidence angles

A laser processing and calibration device technology, which is applied to laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large measurement error, complicated operation, and long time consumption, so as to reduce measurement error, simplify calibration, and improve stability. and process reproducibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

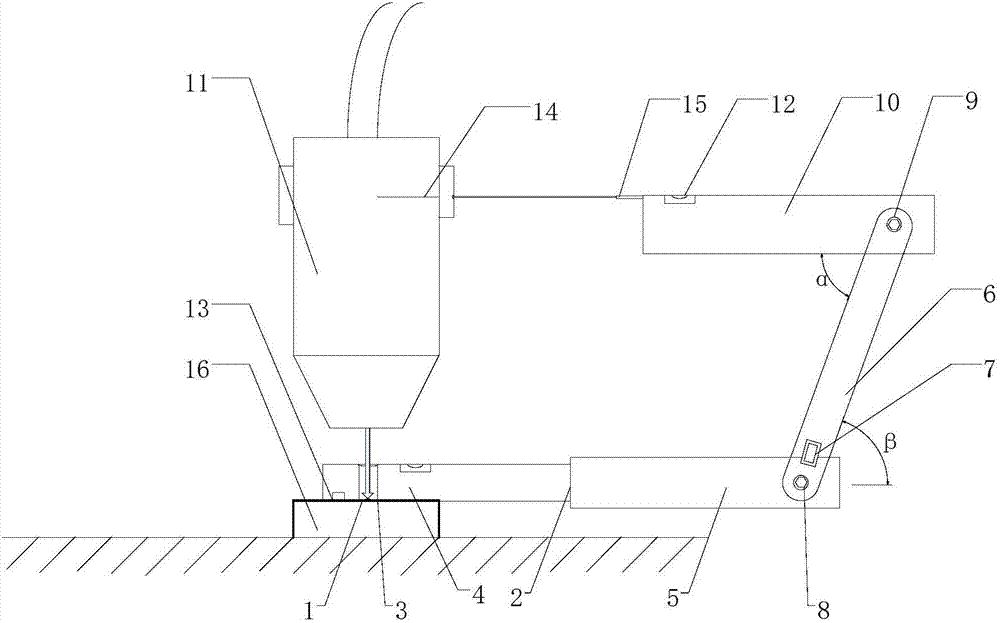

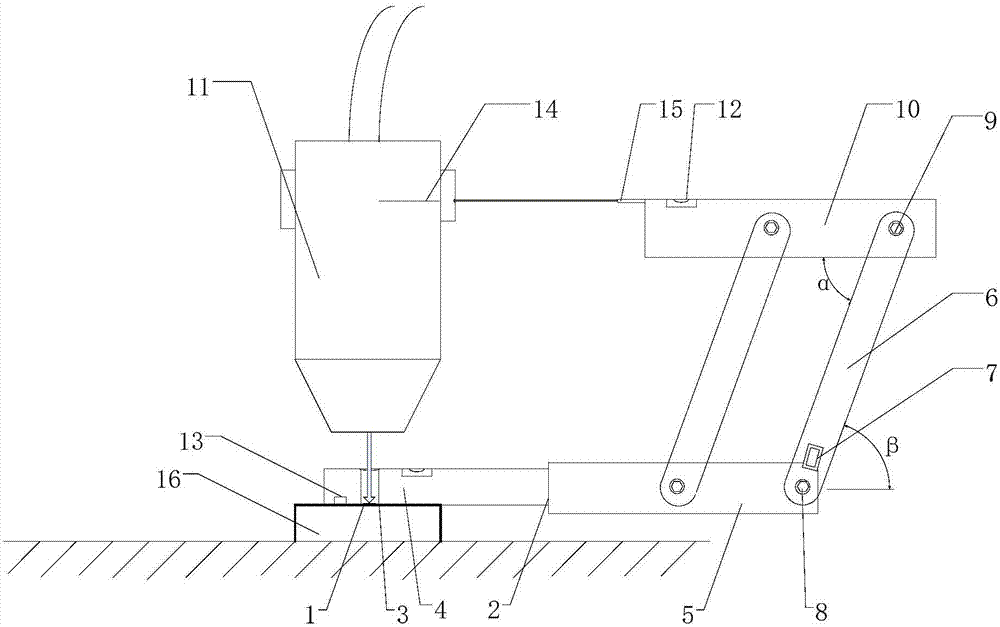

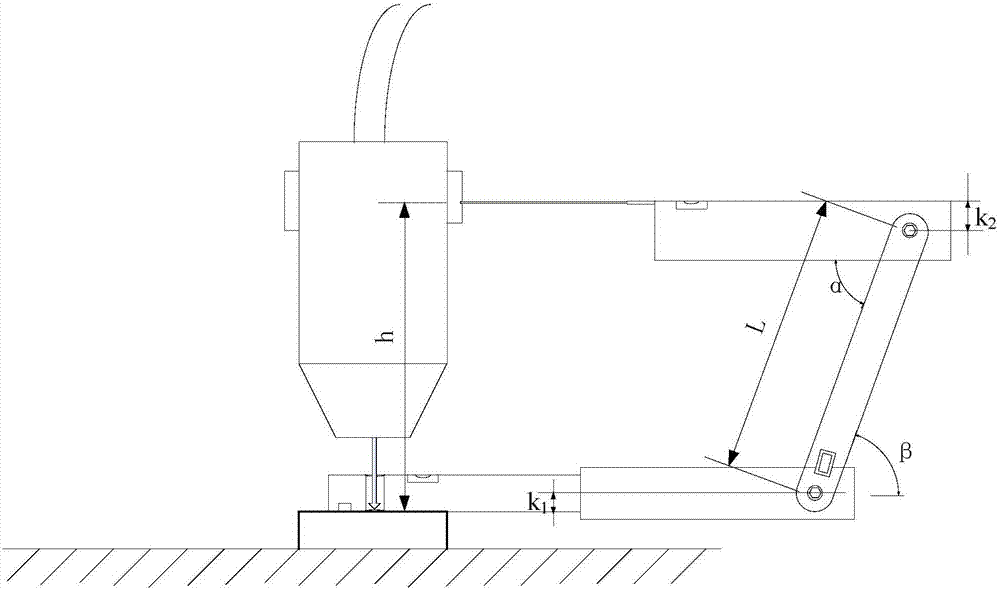

[0024] Such as figure 1 As shown, the present invention provides a measurement and calibration device for focal length and incident angle of laser processing, which includes a telescopic measuring ruler 2 , a connecting rod 6 and an upper measuring ruler 10 . The telescopic measuring ruler 2 is connected with the upper measuring ruler 10 through the connecting rod 6 .

[0025] The telescopic measuring ruler 2 includes a fixed part 5 and a movable ruler part 4, the movable ruler part 4 is assembled on the fixed part 5, and can slide along the fixed part 5; the protruding end of the movable ruler part 4 is provided with a penetrating movable The laser beam incident verticality calibration hole 1 of the ruler part 4 is equipped with a concentric ring target 3 on the upper hole surface and the lower hole surface of the laser beam inciden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com