Welding electrode end cleaning device

A cleaning device and welding rod technology, which is applied in the direction of grinding machine parts, grinding machines, metal processing equipment, etc., can solve problems such as incomplete contact and affecting welding quality, and achieve improved welding quality, convenient adjustment, and good contact conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

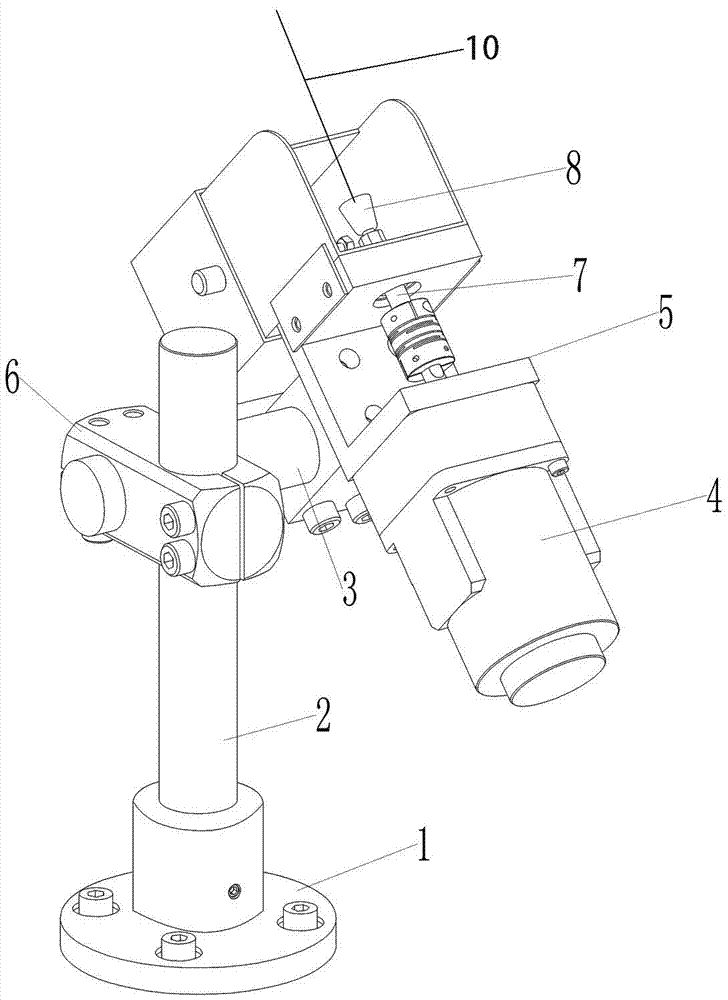

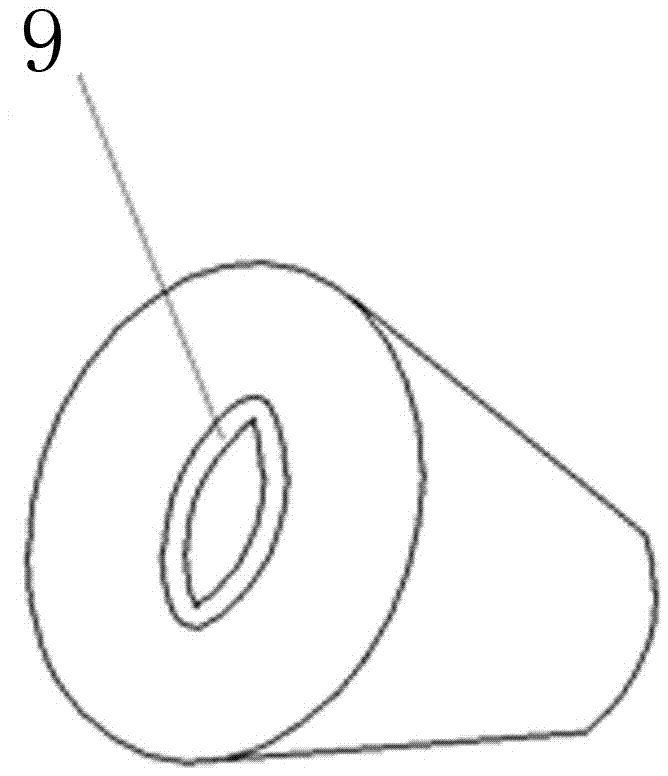

[0008] figure 1 , 2 Middle: base 1, upright column 2, horizontal column 3, motor 4, motor base 5, connector 6, rotating shaft 7, cleaning sleeve 8, inner core 9, welding rod 10.

[0009] An electrode end cleaning device, the electrode end cleaning device includes a base 1, a column 2, a horizontal column 3, a motor 4, and a cleaning mechanism, the lower end of the column 2 is fixedly connected to the base 1, the The column 2 is movably connected with the connector 6, and the connector 6 is movably connected with the horizontal column 3, and the horizontal column 3 is movably connected with the motor base 5, and the connector 6 surrounds the device connector as shown in the figure. The central axis of the column 2 rotates, and rotates around the central axis of the horizontal column 3 at the same time. At the same time, the connector 6 can be adjusted along the vertical axis of the column 2, and can also be adjusted along the axial direction of the horizontal column 3, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com