Continuous efficient fractional distillation device and technical method

A fractional distillation and equipment technology, which is applied in the field of wine distillation equipment and technology, can solve the problems of single distilled wine and cannot be graded, and achieve the effect of continuous process, natural taste and avoiding continuous distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

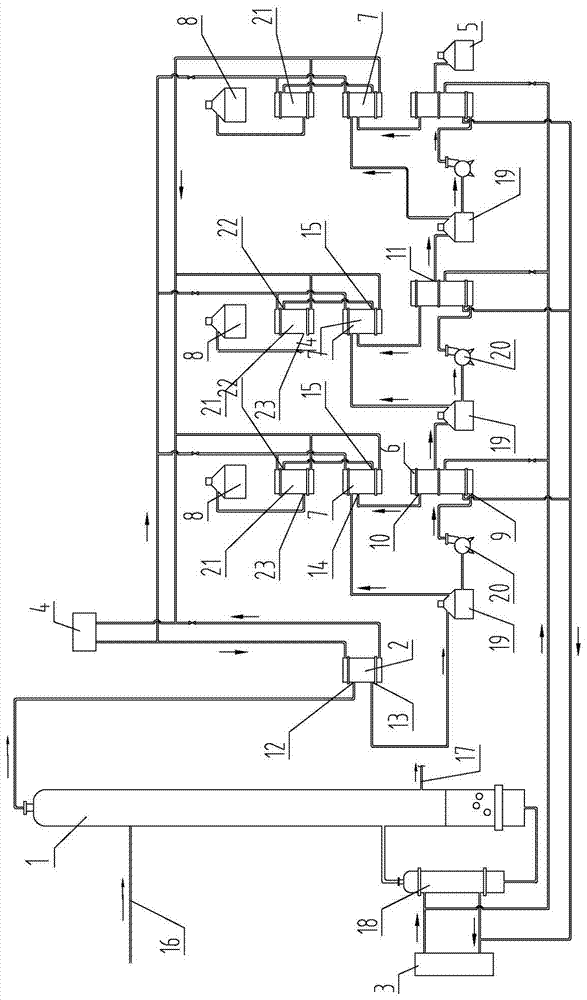

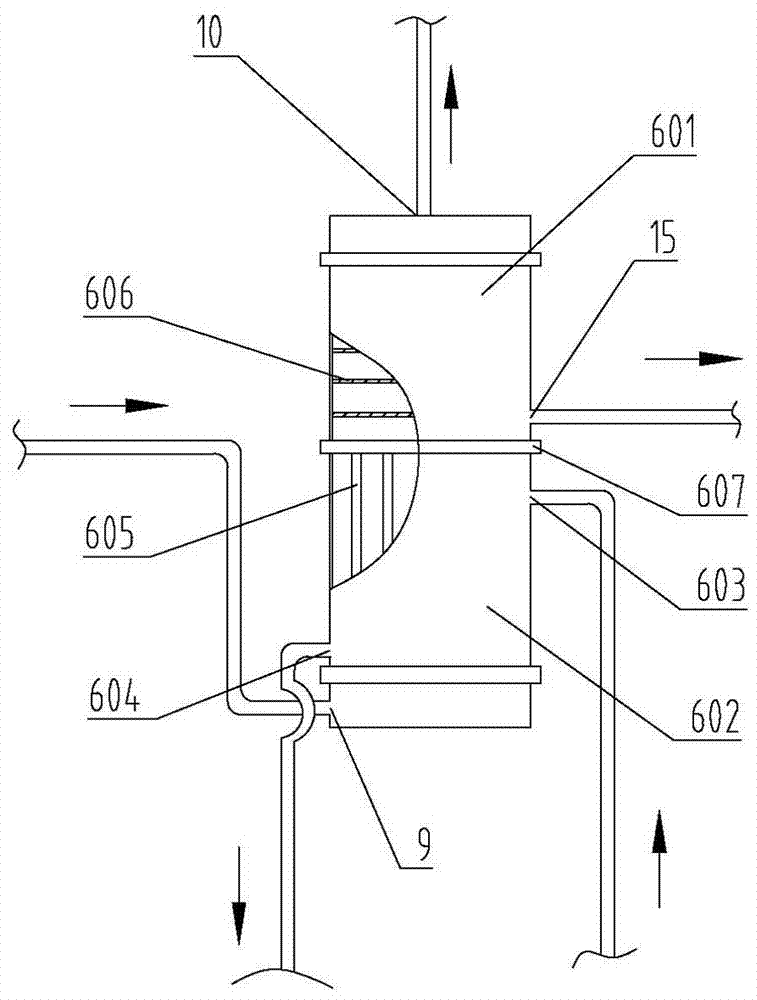

[0017] Example 1, such as figure 1 , 2 As shown, the continuous high-efficiency fractional distillation equipment includes a distillation tower 1, a main condensing device 2, a heat source 3, a cold source 4, a grape water tank 5 and at least one level of fractional distillation equipment; each level of fractional distillation equipment includes a distillation box 6 , grading condensing device 7, finished product storage tank 8; Distillation box 6 is provided with the grading feed inlet 9 that is convenient for wine liquid to enter, the grading gas outlet 10 that is convenient for wine vapor to discharge, the grading liquid outlet 11 that is convenient for wine liquid discharge, main The condensing device 2 is provided with a main condensing feed port 12 for the entry of wine vapor and a main condensing discharge port 13 for the discharge of the cooled wine liquid, and the grading condensing device 7 is provided with a grading condensing feed port for the entry of wine vapor ...

Embodiment 2

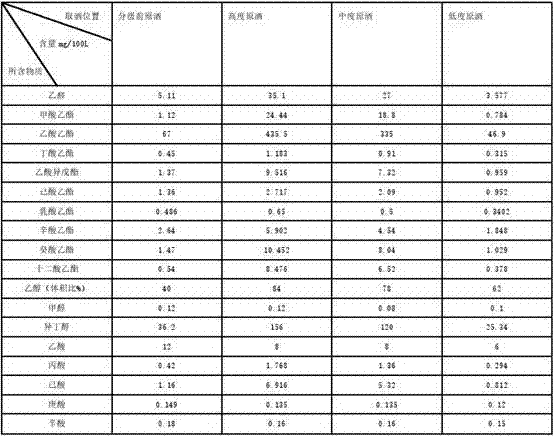

[0022]Example 2, the continuous high-efficiency fractional distillation process includes the following steps: the first step, the fermented mash is sent to the distillation tower 1 for distillation, the bottom temperature of the distillation tower 1 is 75°C to 110°C, and is controlled according to the type of tower still The steam pressure and the flow rate of the fermented mash are used to obtain wine vapor with an alcohol concentration of 20%vol to 35%vol and send it to the main condensing device 2. Part of the remaining raffinate in the distillation tower 1 returns to the reboiler 18 to generate steam, and part of it passes through the residual liquid. The liquid discharge pipe 17 is discharged; the second step, the wine vapor obtained in the above steps passes through the main condensing device 2 and the condensation temperature is 40 ℃ to 60 ℃ before the graded raw wine; the third step, the graded former wine obtained in the second step passes through the Graded distillati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com