Tunnel engineering spray-filming waterproofing construction device and construction method

A spray film waterproofing and construction device technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of broken waterproof membranes, difficulty in meeting water blocking requirements, and inability to adhere to concrete, so as to prevent uneven thickness , Improve the sealing performance, improve the effect of range and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

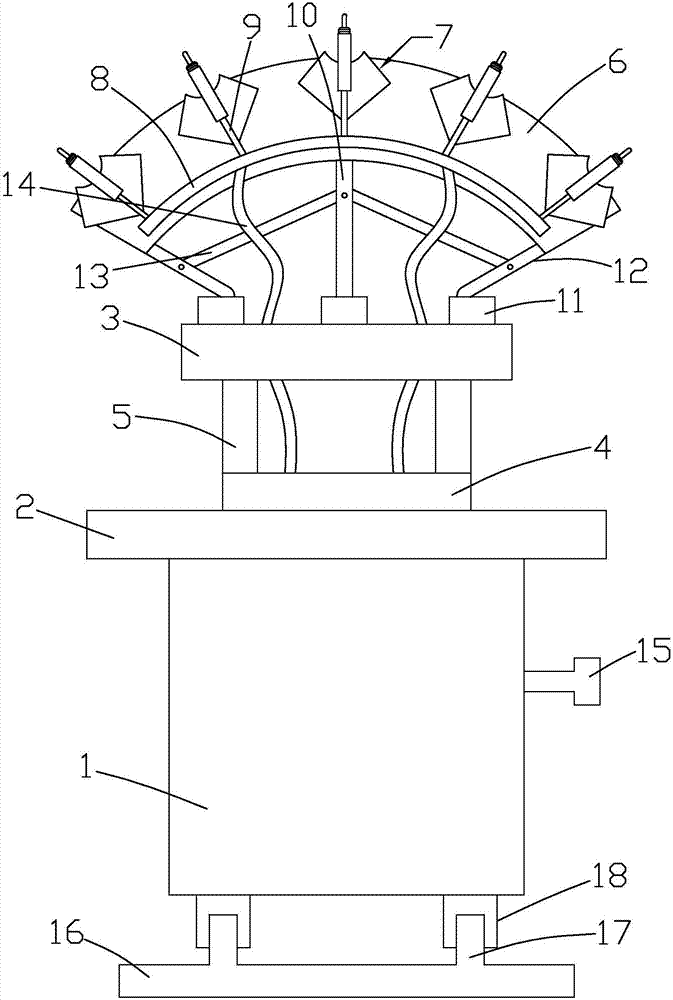

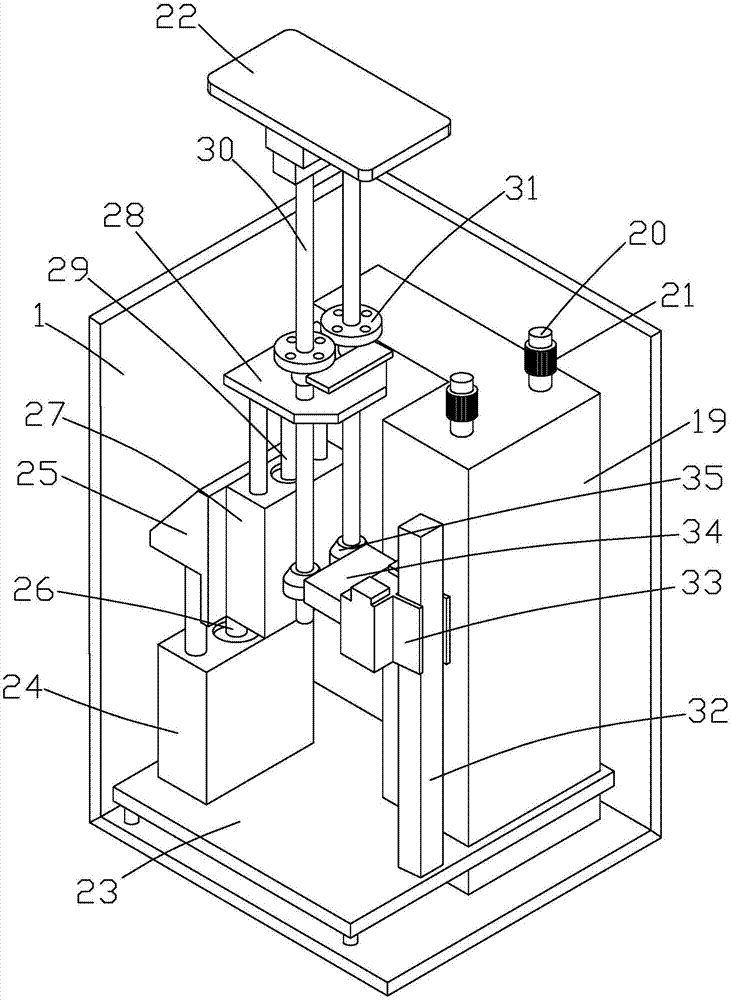

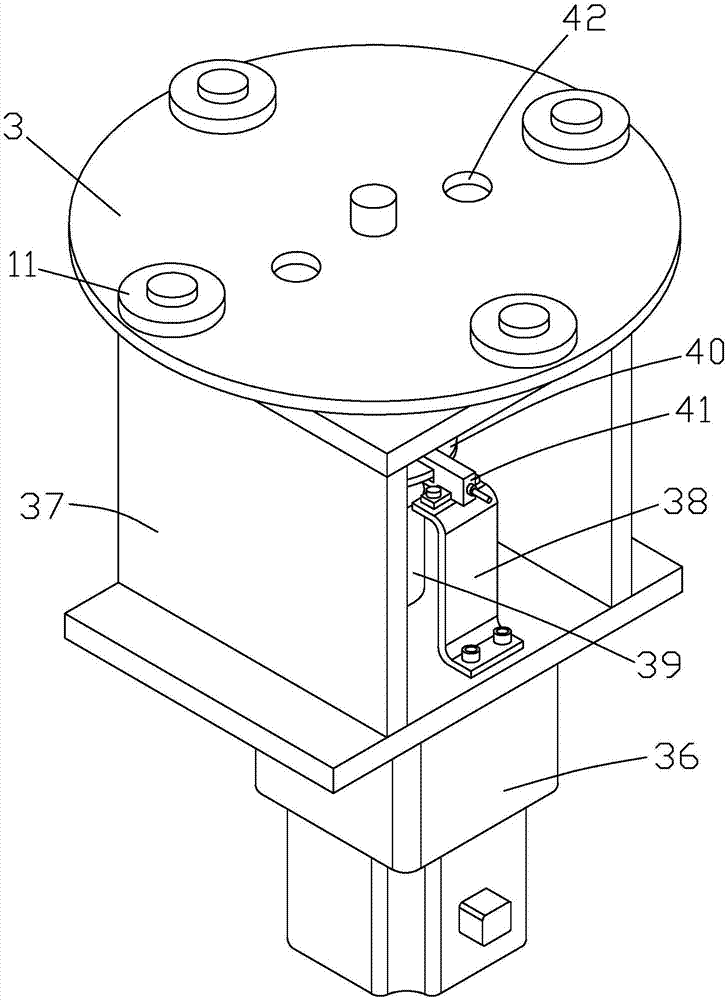

[0047] Such as Figure 1 to Figure 4 Shown, be a kind of tunnel engineering spray film waterproof construction device of the present invention, comprise box body 1, bottom plate 16, lifting mechanism, material storage box 19, rotating mechanism and spray film waterproof mechanism 7, be provided with on the top surface of box body 1 The end cover 2 and the bottom plate 16 are located below the box body 1. Two horizontal guide rails 17 parallel to each other are arranged on the bottom plate 16. Pulleys 18 are arranged on the bottom surface of the box body 1. The pulleys 18 match the horizontal guide rails 7 and pass through the horizontal guide rails. The design of 17 can make the spray film waterproof construction device move straight along the horizontal direction, improve the uniformity of spray film, prevent uneven thickness, and improve the flexibility of movement at the same time.

[0048] The lifting mechanism and the material storage box 19 are all located in the casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com