Specimen disc positioning device of total reflection X-ray fluorescence spectrophotometer

A fluorescence spectrometer and positioning device technology, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of difficulty in measuring solid dust particles, affecting sample insertion and removal, and inconvenient instrument debugging, etc., and achieves convenient instrument debugging. And the effect of loading and placing samples and positioning, convenient loading and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

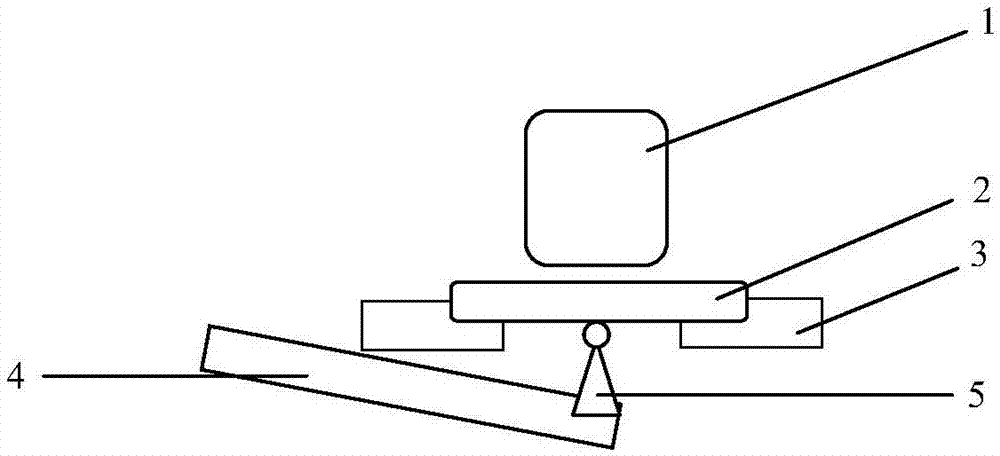

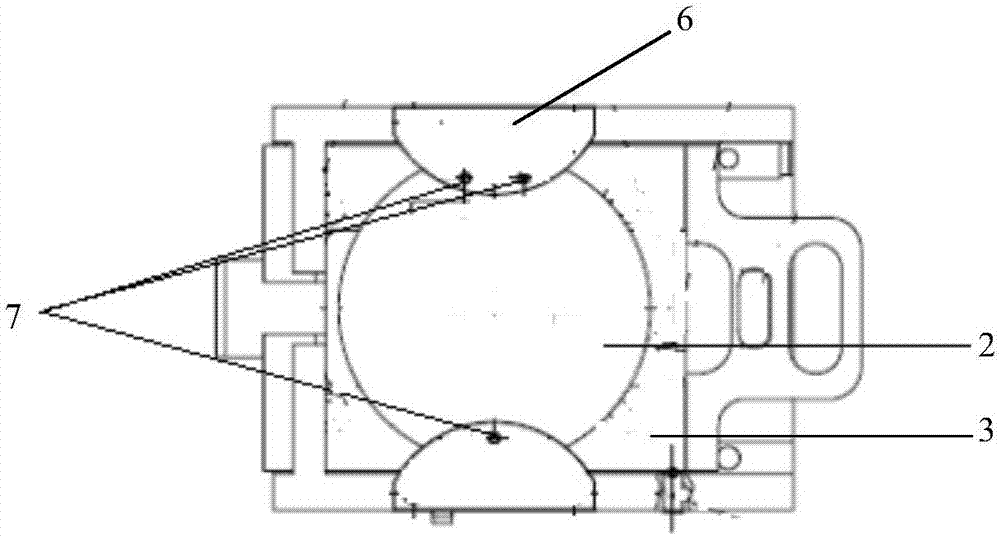

[0019] Such as figure 1 As shown, the sample tray positioning device of the total reflection X-ray fluorescence spectrometer provided by the present invention includes a sample tray rack 3 located below the detector 1, the bottom surface of the sample tray rack 3 can be drawn horizontally, and the sample tray 2 is horizontally arranged on the sample tray On the bottom surface of the rack 3, a pressing device is provided below the bottom surface of the sample tray rack. The pressing device includes a pressing plate 4 arranged obliquely and a pressing member 5 located at the end of the pressing plate. Positioning means.

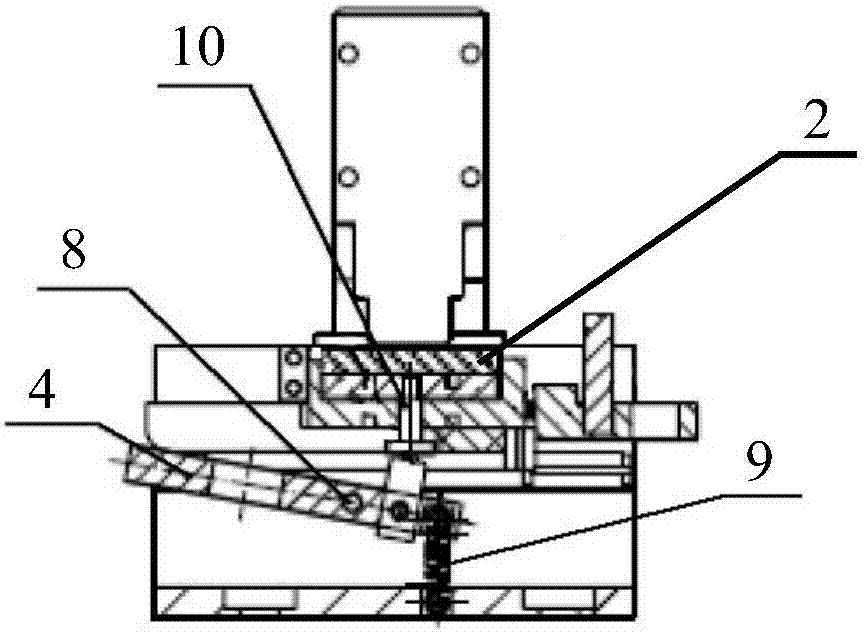

[0020] As a specific embodiment, the structure of the pressing device is as figure 2 As shown, the pressing device includes a pressing plate 4 arranged obliquely, and a lifting shaft 10 is connected above one end of the pressing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com