Continuous casting production process data acquisition and monitoring system

A production process and data acquisition technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of restricting production process, product quality in production process, difficult to meet the requirements of control mode, poor fault tolerance, etc., to achieve Achieve structural transformation, achieve continuity, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

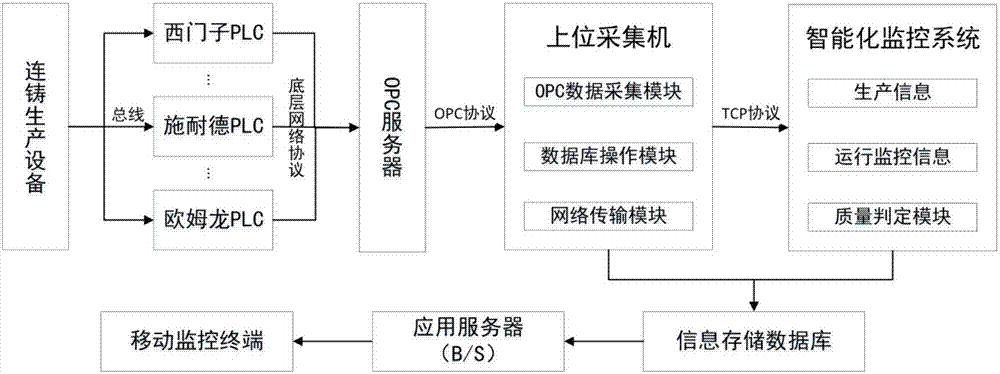

[0023] In the era of industrial informatization, various intelligent monitoring technologies can not only improve the informatization management of industrial production and the automation level of the production process, but also effectively improve production efficiency. The present invention designs a continuous casting production process data collection and monitoring system, which realizes the data cache function from the collection interface, not only can conveniently and effectively collect real-time data from different PLC devices on the production site, but also provides mobile intelligent monitoring services, It can effectively meet the functional requirements of the new generation of real-time production data collection, intelligent monitoring of the production process and information integration.

[0024] see figure 1 , the continuous casting production process data acquisition and intelligent monitoring system of the present invention includes production equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com