Warehouse material management system and method

A management system and management method technology, applied in logistics, data processing applications, instruments, etc., can solve the problems of increasing production material costs, material loss, etc., and achieve the effect of avoiding losses and facilitating unified management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

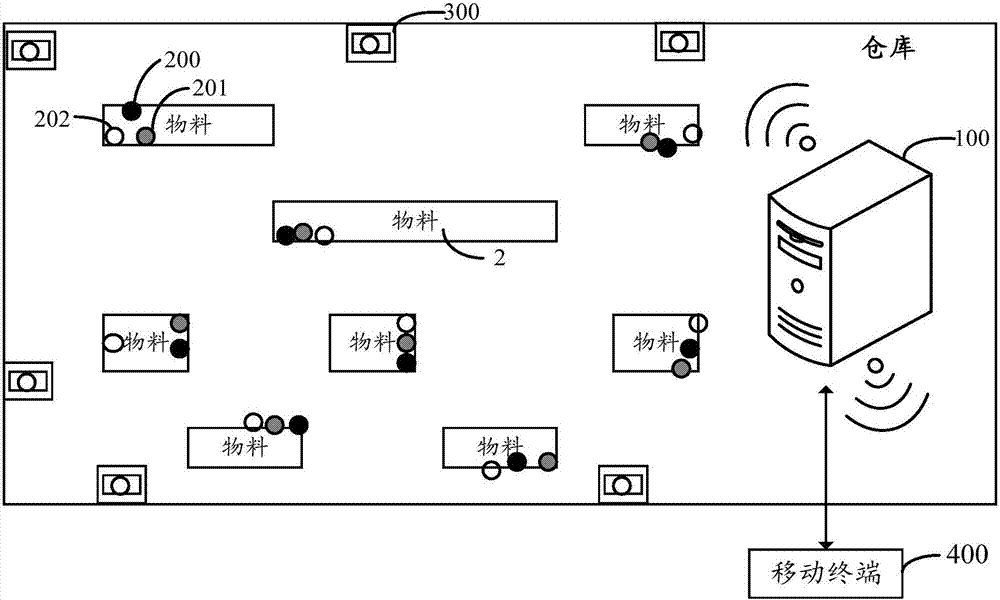

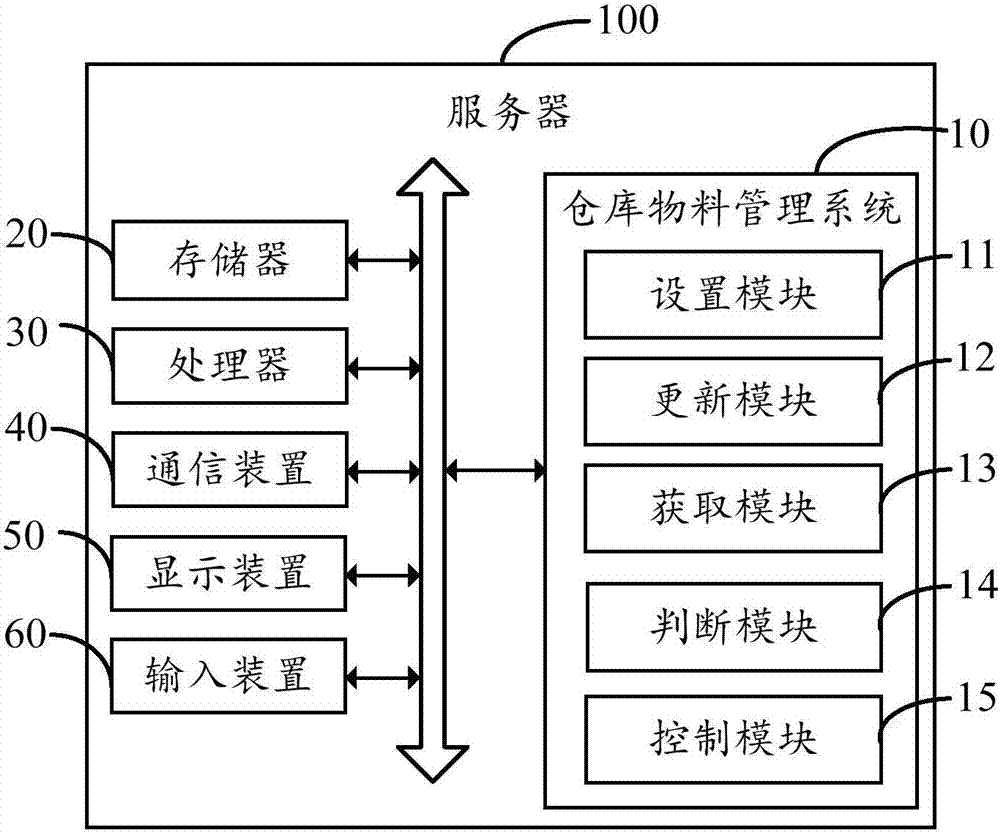

[0042] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the application environment of the warehouse material management system in an embodiment of the present invention, figure 2 It is a schematic diagram of the functional modules of the warehouse material management system 10 in an embodiment of the present invention. The warehouse material management system 10 is installed and operated on such as figure 1 The server 100 shown is used to manage the materials 2 in the warehouse.

[0043] Such as figure 1 As shown, a plurality of unit materials 2 are placed in a warehouse, and a positioning label 200 is pasted on the outside of each unit material 2. Cameras 300 are installed at various positions in the warehouse to monitor the situation in the warehouse. to shoot. The positioning tag 200 is an electronic tag with an indoor precise positioning function. Each positioning tag 200 is also provided with a sounding device 201 and a light emitting device 202....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com