Patents

Literature

45 results about "Warehouseman" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A warehouseman can be someone who works in a warehouse, usually delivering goods for sale or storage, or, in older usage, someone who owns a warehouse and sells goods directly from it or from a shop fronting onto the warehouse (similar to a modern Cash and carry).

Intelligent warehouse management system and method

InactiveCN102147888AShorten working timeFast transferData processing applicationsCo-operative working arrangementsInformatizationInformation sharing

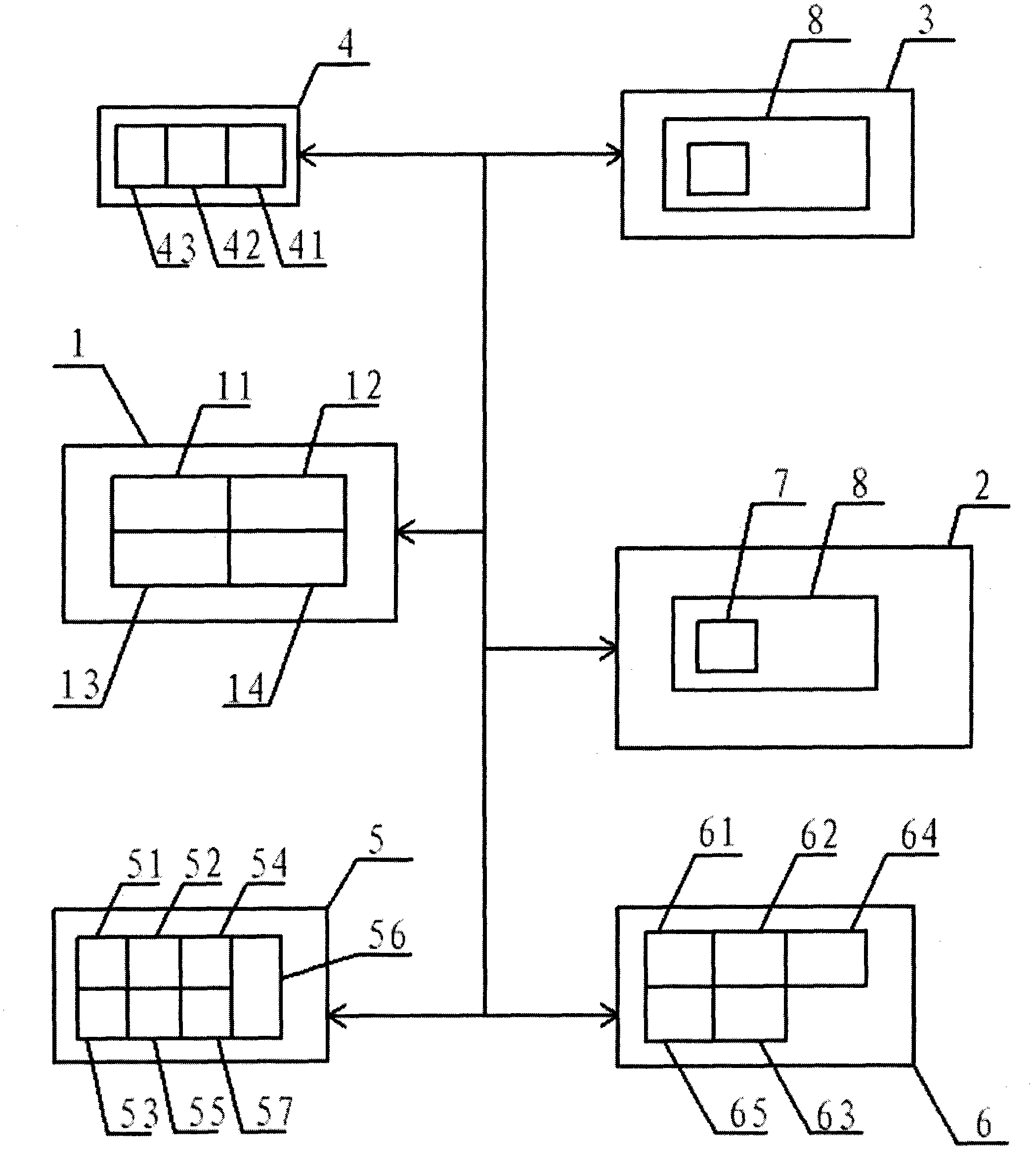

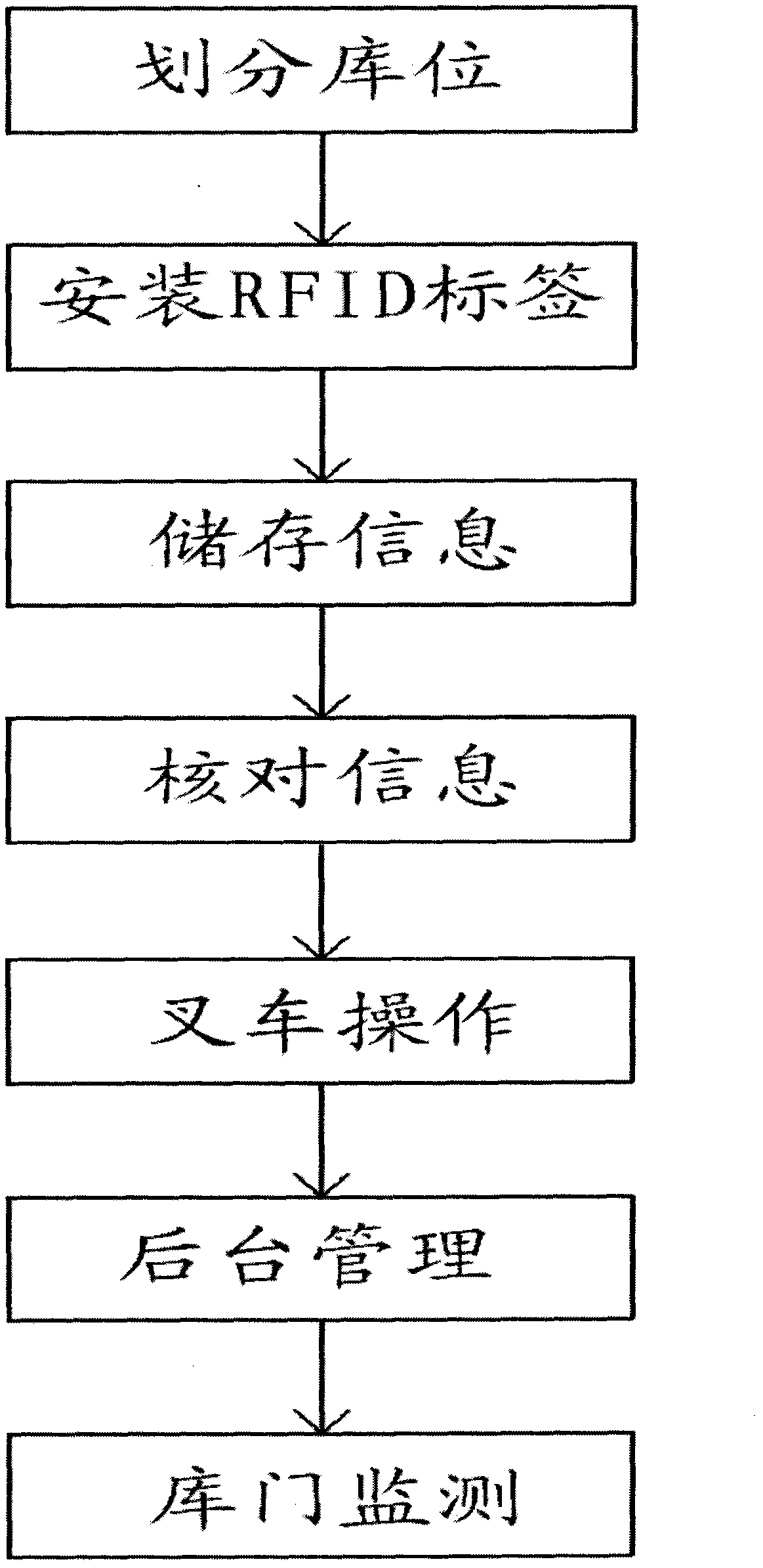

The invention discloses an intelligent warehouse management system and a method. The intelligent warehouse management system comprises a data processing device, an RFID (radio frequency identification device) warehouse location and an RFID tray, wherein the RFID warehouse location and the RFID tray are respectively provided with an RFID electronic tag and are connected with the data processing device in a wireless way; the system further comprises a handheld terminal, a vehicle-mounted terminal and a gate terminal, wherein the handheld terminal is carried by a warehouse keeper, the vehicle-mounted terminal is arranged on a forklift, and the gate terminal is arranged at a gate of a warehouse; and the handheld terminal, the vehicle-mounted terminal and the gate terminal are respectively connected with the data processing device in a wireless way. The system has the main functions of improving efficiency, replacing manual input of information after operation, leading transmission and recording of the information to be more rapid and accurate, mastering the storage condition of warehouse goods and the service condition of the warehouse in real time, greatly accelerating the process of enterprise informatization and promoting information sharing among all departments of the enterprise.

Owner:NINGBO TONGYI WULIAN TECH

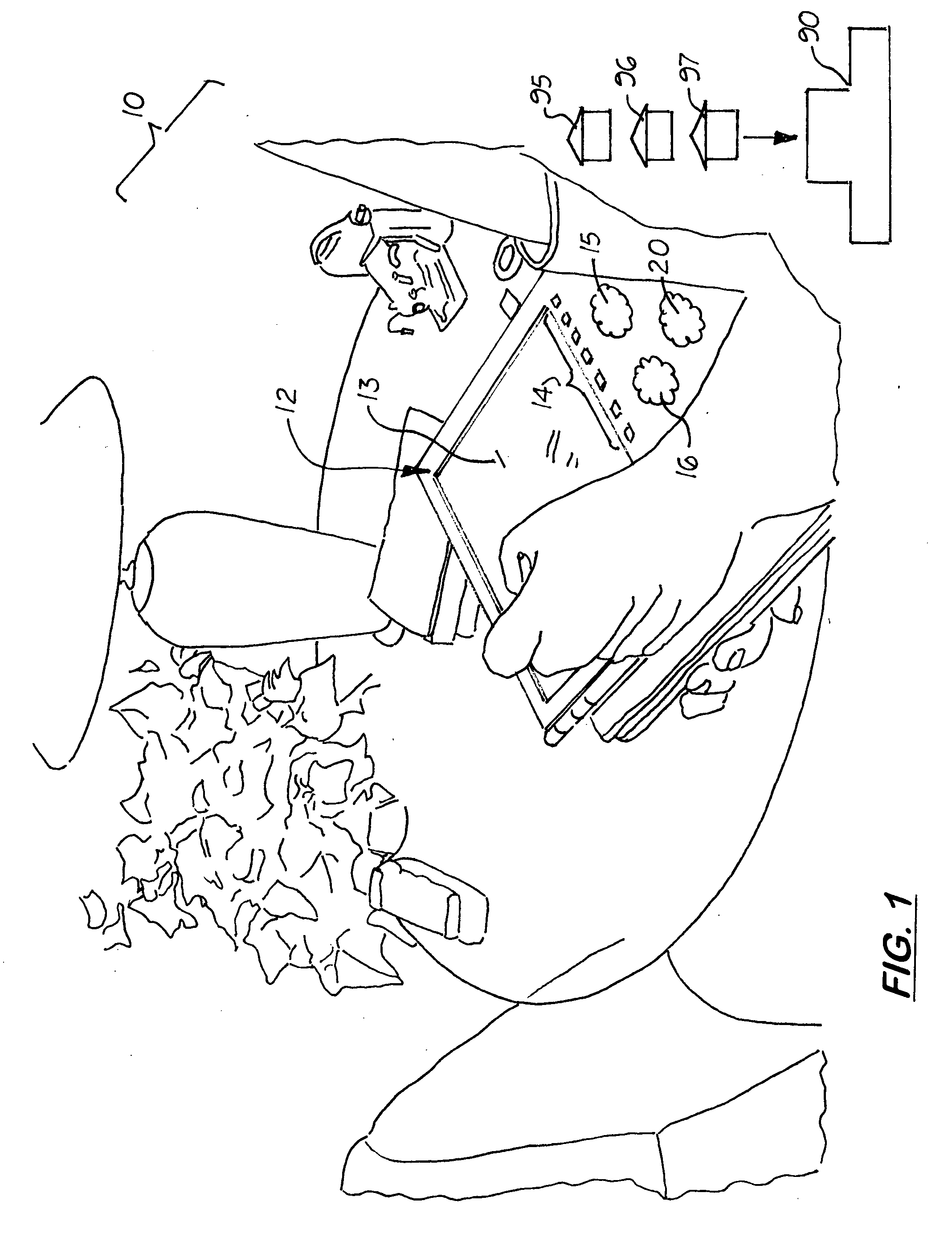

Graphic driven moving personal property tracking system and method

InactiveUS20060106652A1Accurately and easily recordingAccurate monitoringFinanceCathode-ray tube indicatorsGraphicsHand held

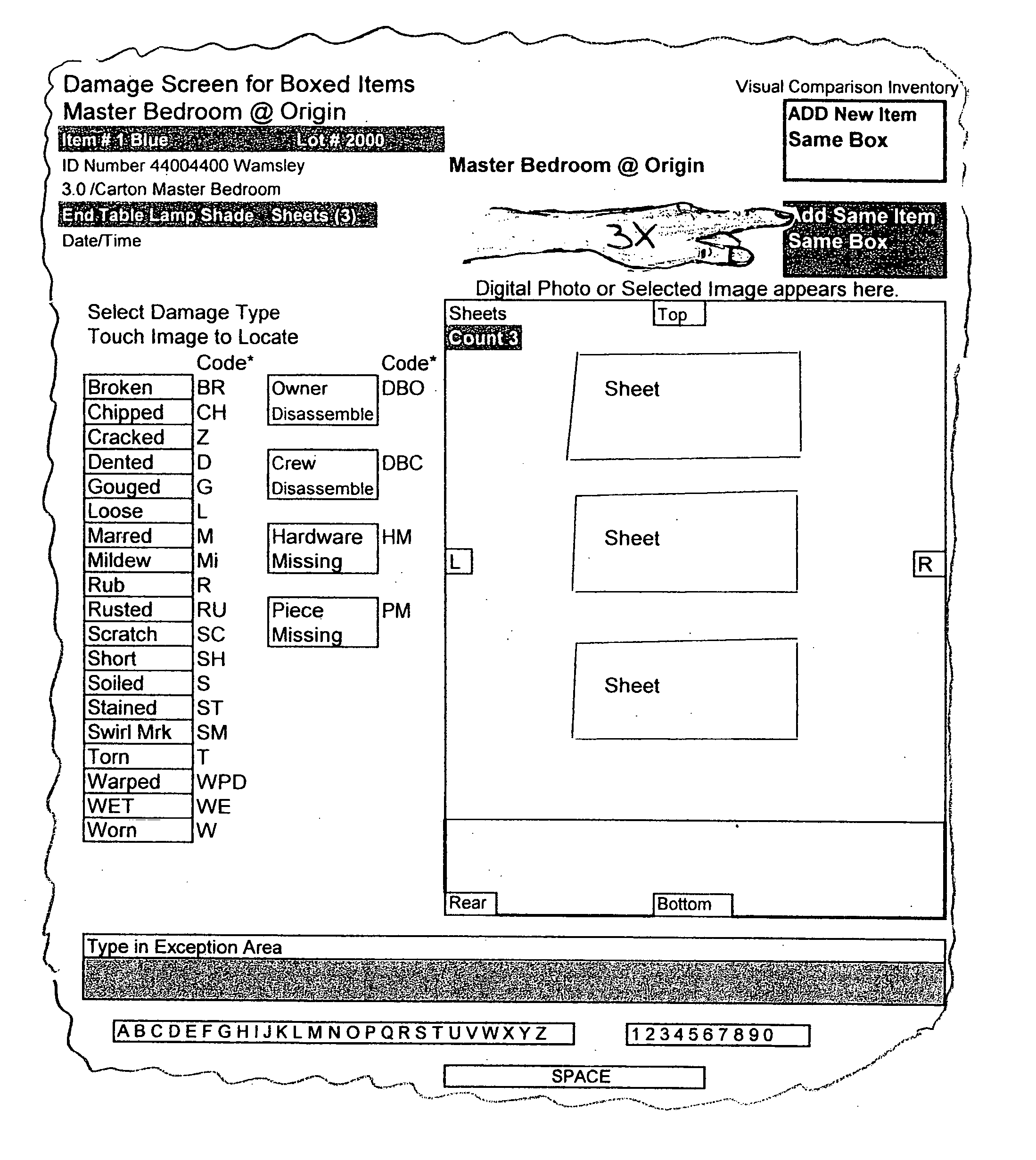

A graphic driven moving personal property tracking system that enables the company to monitor and track its customer's personal property during transport and to identify the various parties in the chain of custody. The system uses a hand held device that enables the packing company to accurately inventory and record the initial condition of the personal property prior to packing. Loaded into the memory of the hand held device is a building layout software program that visually presents images of different pieces of the personal property in selected rooms. When a room is selected, a list of personal property normally found in the room is presented. When damage is detected on the personal property prior to packing, the user selects the personal property and records precise location of the damage. When all of the personal property has been recorded, a written report is generated and delivered to the customer who then verifies the information. During the packing stage, an identifying code is assigned to each piece of personal property or to its outer container. When the personal property is moved between the hauling company, the warehouseman, and the unpacker, the handheld device is used to record the chain of custody and the condition of the property.

Owner:WAMSLEY DAVID A

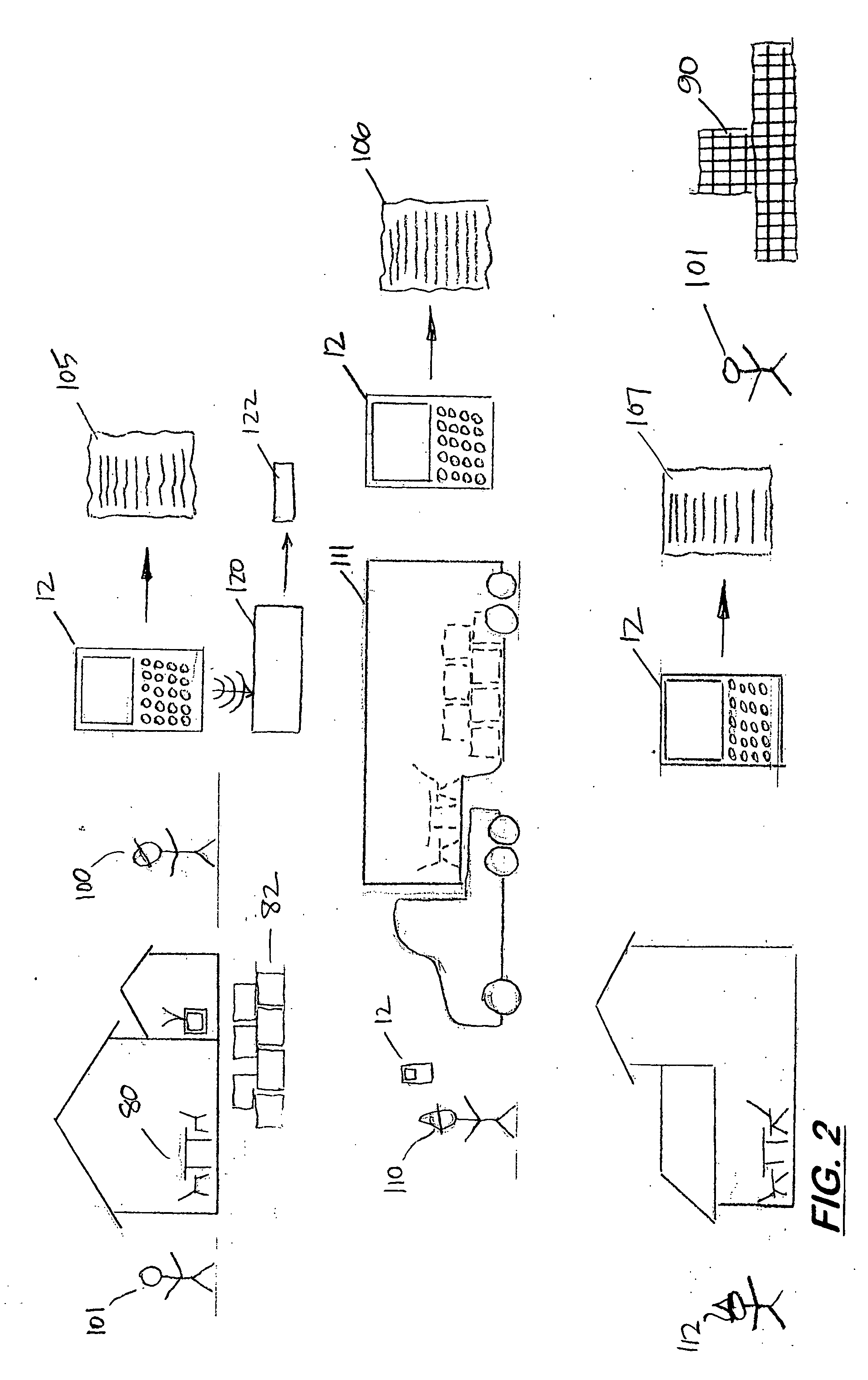

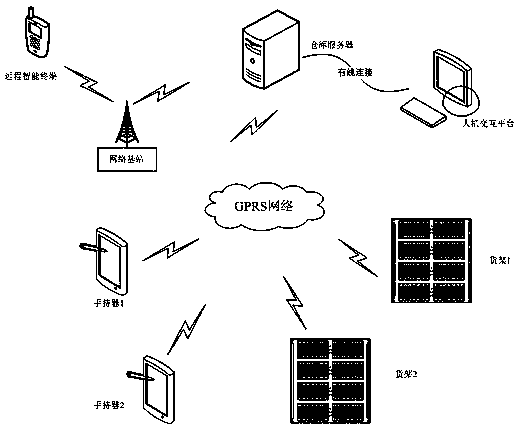

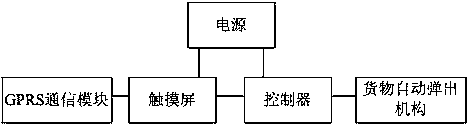

Intelligent warehouse management system and management method

InactiveCN104809609ASave yourself the trouble of findingShorten the timeLogisticsApproaches of managementIntelligent management

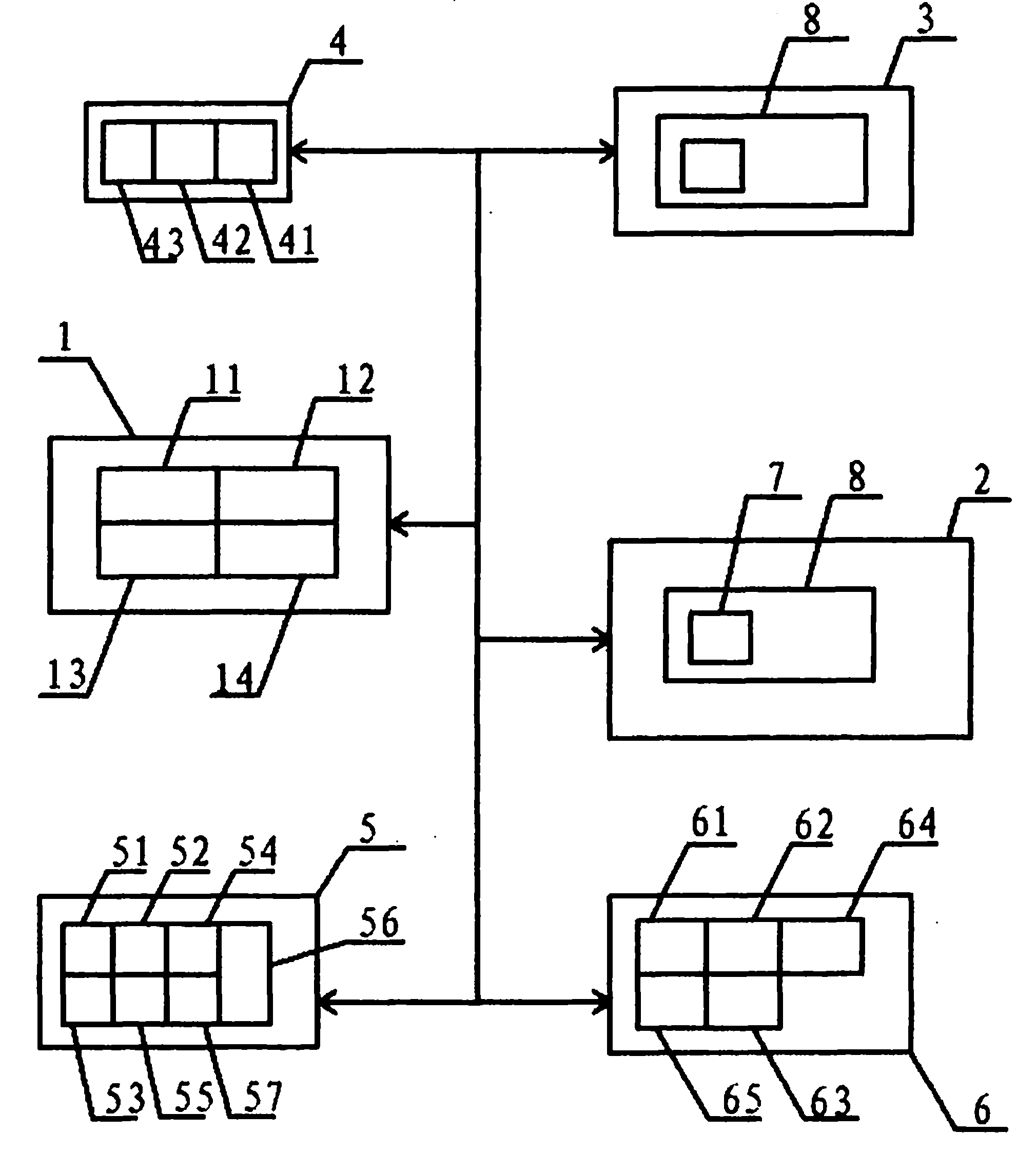

The invention discloses an intelligent warehouse management system and management method. The intelligent warehouse management system comprises a remote intelligent terminal, a warehouse server, a human-computer interaction platform, a plurality of shelves and handheld terminals, wherein the human-computer interaction platform, the shelves and the handheld terminals are connected with the warehouse server; the remote intelligent terminal and the warehouse server realize data interaction via a wireless communication way; the human-computer interaction platform and the warehouse server are in wired connection; the remote intelligent terminal, the handheld terminals and the shelves carry out cargo information query in a wireless communication way. The invention discloses the intelligent warehouse management system, data transmission between a client and a warehouse is realized in the wireless communication way, meanwhile, intelligent management is realized in the warehouse, the position of a cargo is automatically identified, and a complex cargo counting work for warehouse administrators is omitted.

Owner:NANTONG VOCATIONAL COLLEGE

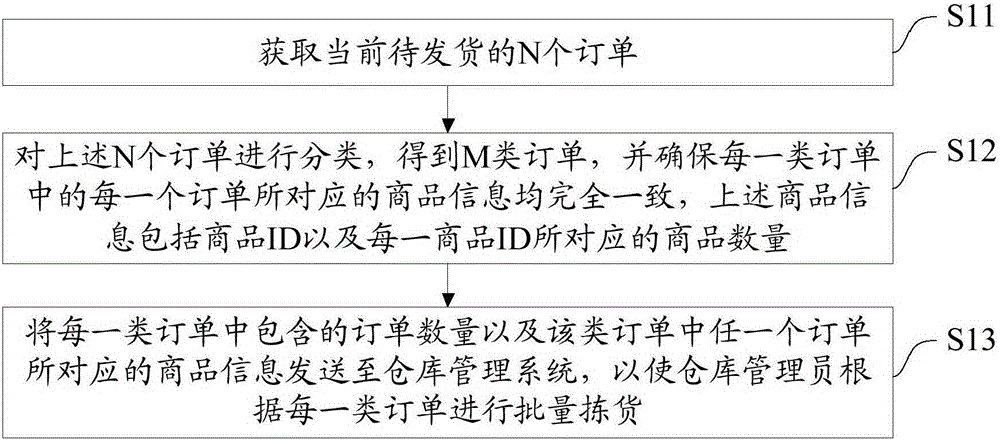

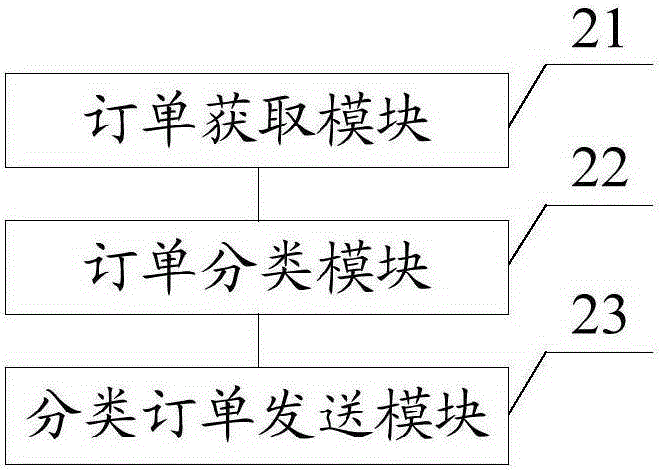

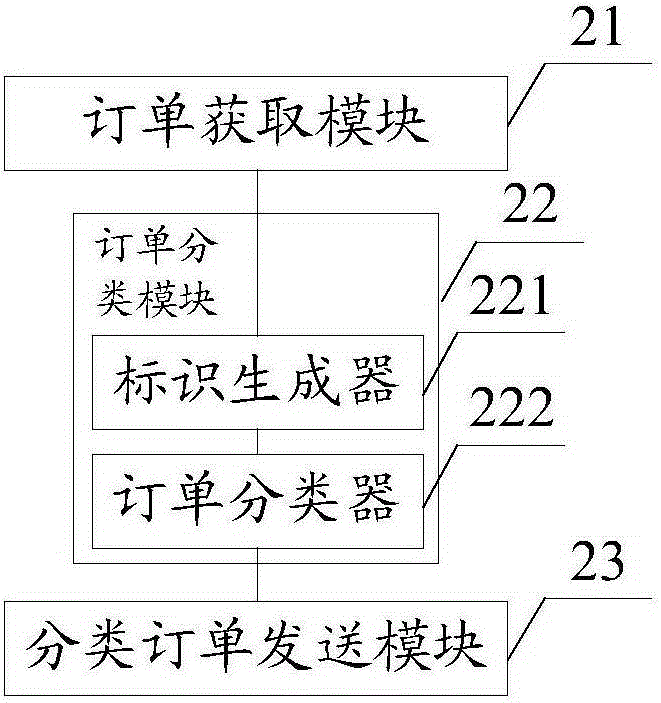

Hot selling query based quick sorting method and system

The application discloses a hot selling query based quick sorting method and system. The method comprises: obtaining current to-be-delivered N orders; classifying the N orders to obtain M types of orders, and ensuring commodity information corresponding to each order in each class of orders to be completely consistent, wherein the commodity information comprises a commodity ID and a commodity quantity corresponding to each commodity ID; and sending an order quantity contained in each type of orders and the commodity information corresponding to any order in the type of orders to a warehouse management system, so that a warehouse keeper performs batch sorting according to each type of orders. According to the quick sorting method and system, the currently obtained to-be-delivered N orders are classified to obtain the M types of orders, and the commodity information corresponding to each order in each type of orders is ensured to be completely consistent, so that the warehouse keeper can perform a quick sorting operation according to the order quantity of each type of orders and the corresponding commodity information, and the sorting efficiency is improved.

Owner:HUNAN YUJIA TECH CO LTD

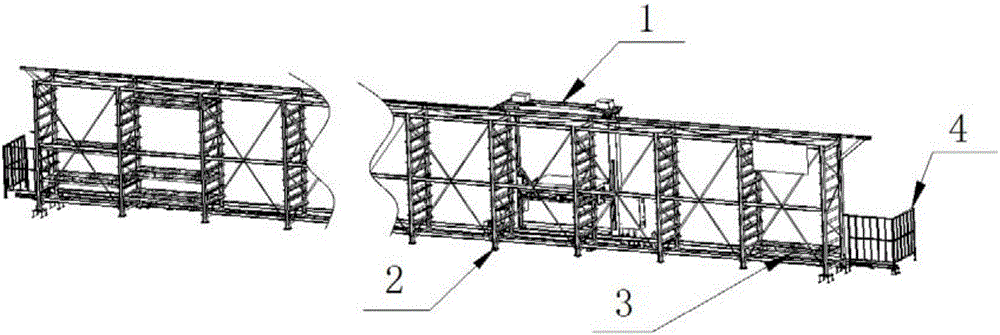

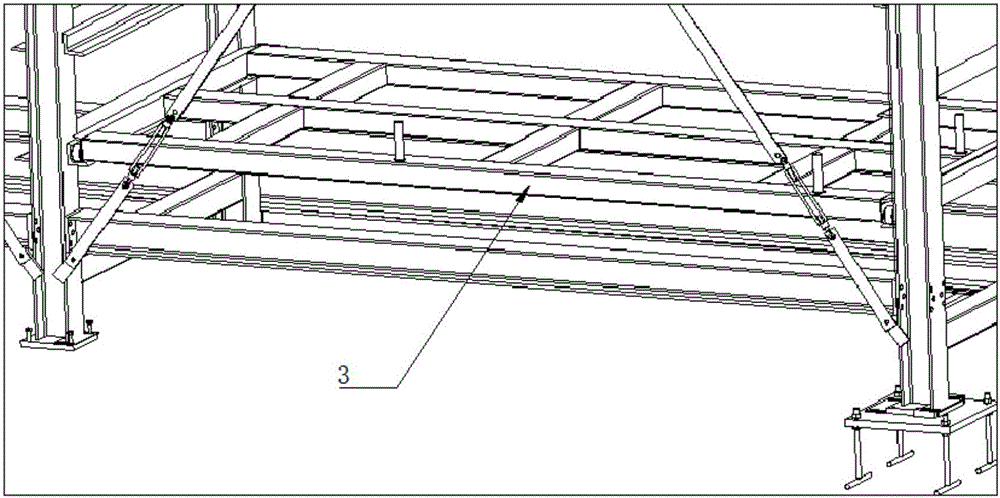

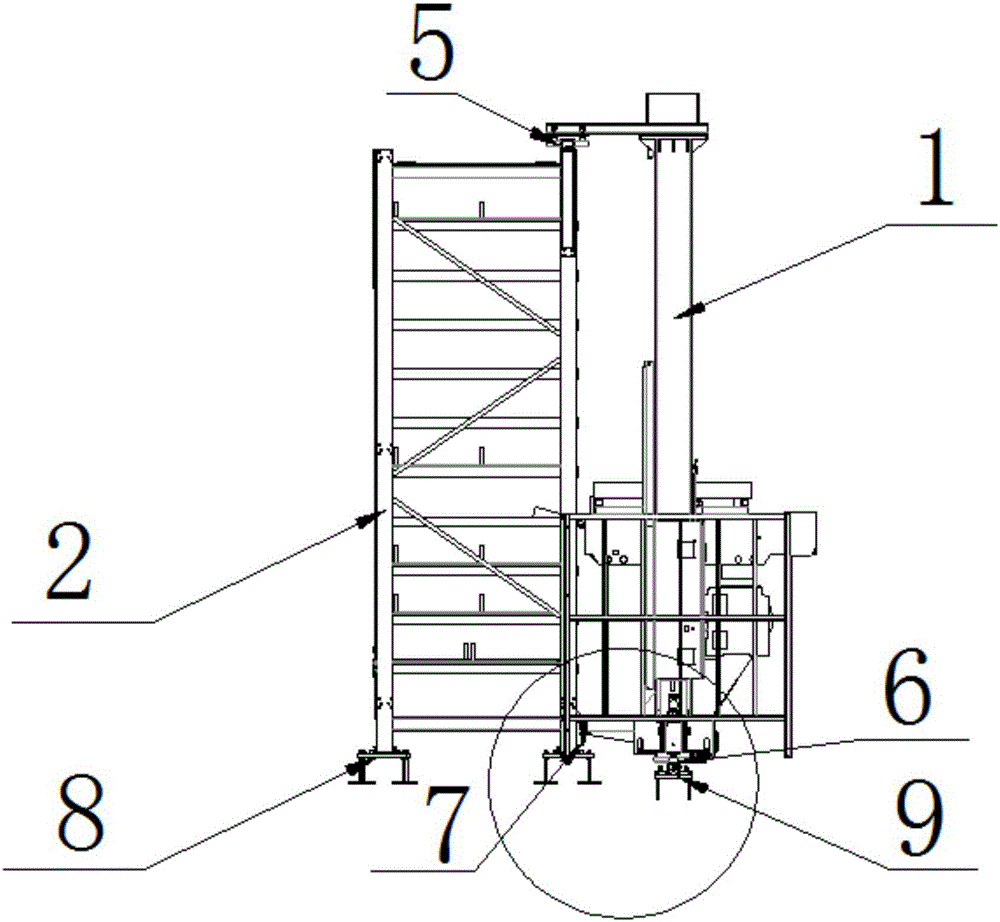

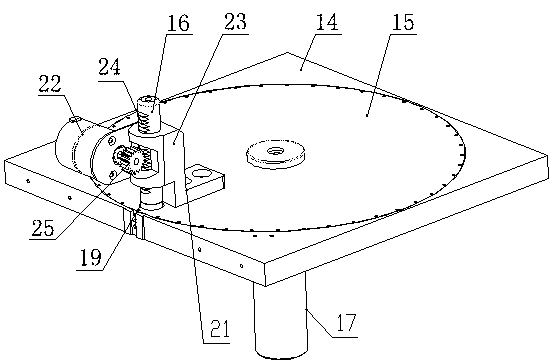

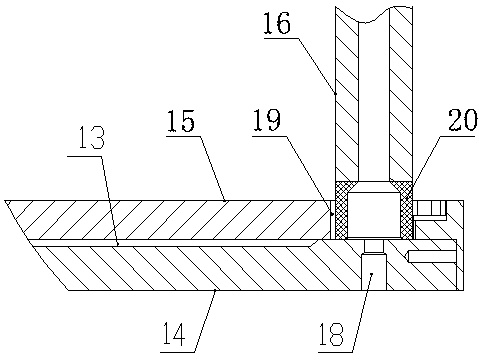

Automatic three-dimensional warehousing equipment

ActiveCN106081453AReduce waiting timeReduce scratchesConveyorsStorage devicesNumerical controlDelivery problems

The invention relates to automatic three-dimensional warehousing equipment. The automatic three-dimensional warehousing equipment comprises a three-dimensional shelf, a heavy-load stacker, a bin tray and a PLC control system. The automatic three-dimensional warehousing equipment is successfully popularized to users and factories, solves the raw material warehousing and automatic delivery problems for enterprises, is in butt joint with a traditional numerical control punching machine of the users to form an automatic production line, can be communicated with user ERP warehouse in-out information to relieve the workload of warehouse keepers, improves the material circulating efficiency, keeps consistent warehouse in-out documents with ERP, automatically finishes actual disc distribution operation at a three-dimensional warehouse end by an automatic stacker, shortens the material preparation waiting time, improves the production efficiency, and improves the enterprise competitiveness from such aspects as labor saving, relief of labor intensity of staff, shortening of the distribution waiting time, reduction of the material scratch and reduction of occupational injury of the staff.

Owner:深圳市固泰科自动化装备有限公司

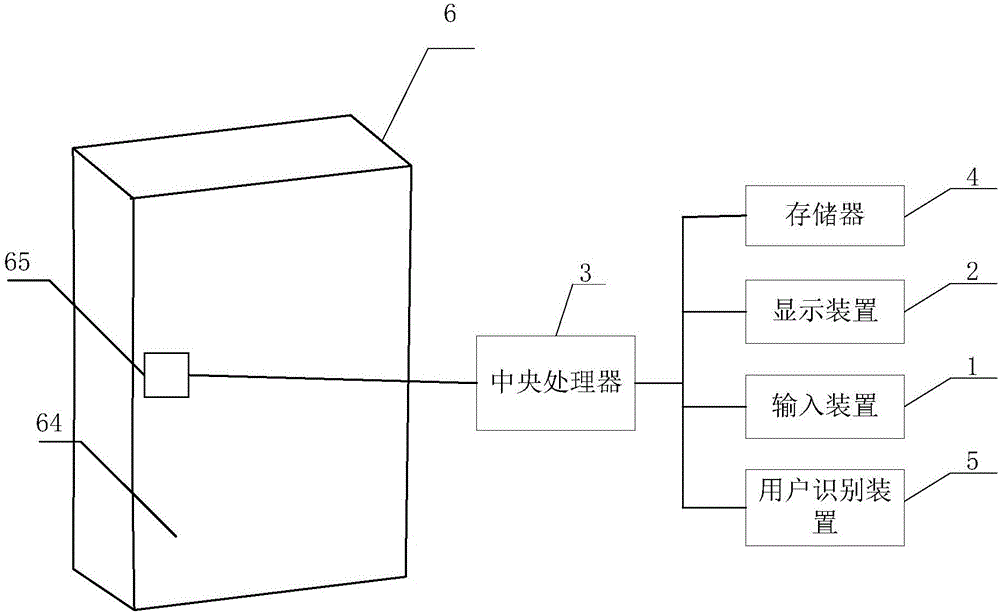

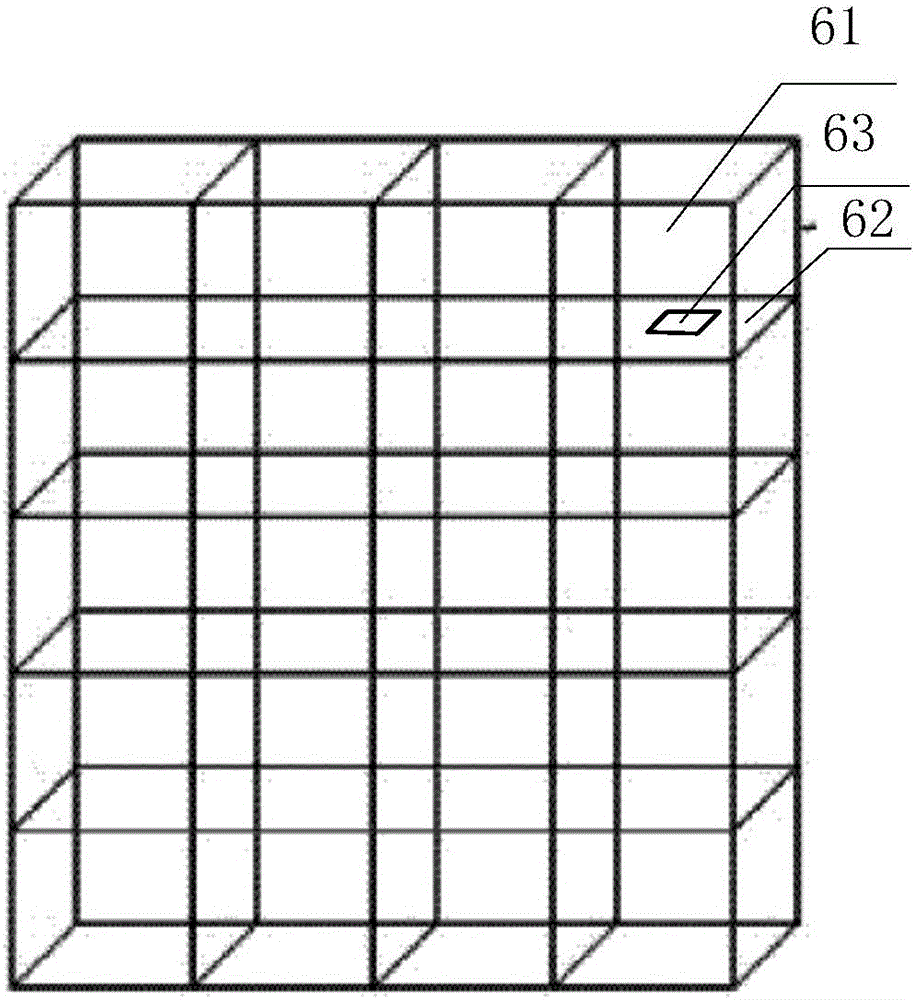

Smart cabinet

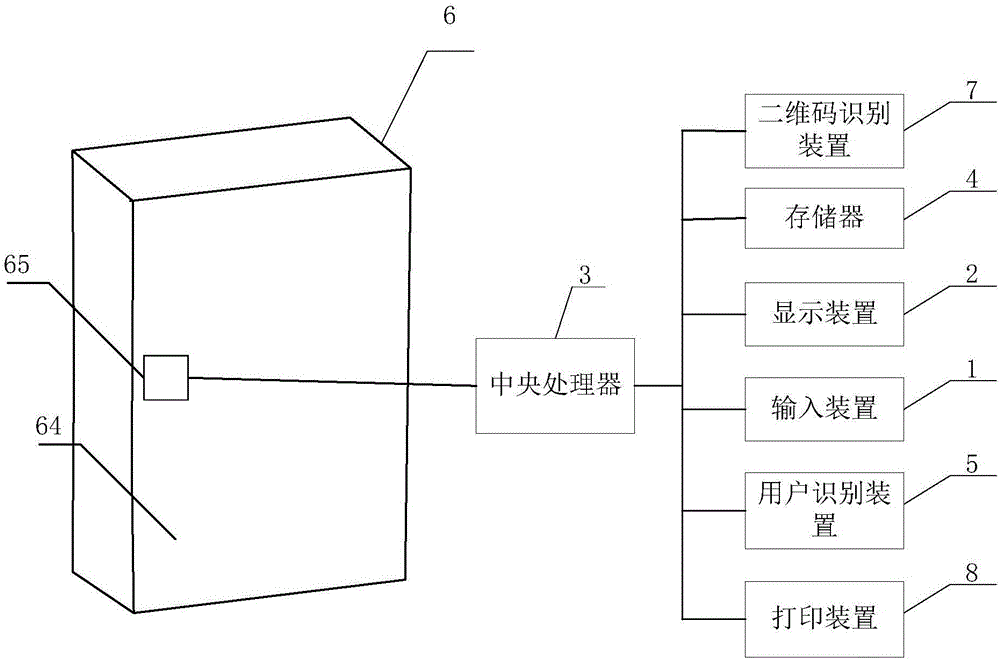

InactiveCN106447942AScientific and reasonable managementCabinetsDigital data authenticationDisplay deviceIdentification device

The invention provides a smart locker, comprising an input device, a display device, a CPU (central processing unit), a memorizer, a user recognition device and a locker body. The CPU is respectively connected with the input device, the display device, the memorizer, a gravity sensor, the user recognition device and an electric control lock, and when doing rush repairs at night or in holidays and festivals, a recipient inputs a material needing to be gotten and corresponding number via the input device, and conducts identity authentication through the user recognition device. The electronic control lock is controlled to open the door of the cabinet, and the recipient gets the corresponding material. The smart locker provided by the invention enables the warehouse management of a power supply station to be more scientific and reasonable, especially for doing rush repairs at night or in holidays and festivals and under the condition that a leader for examination and approval or a warehouse keeper is absent, and the smartcabinet can realize fastness and convenience very well, which are brought by unattended operation and automatic material getting.

Owner:STATE GRID ZHEJIANG YONGJIA POWER SUPPLY +3

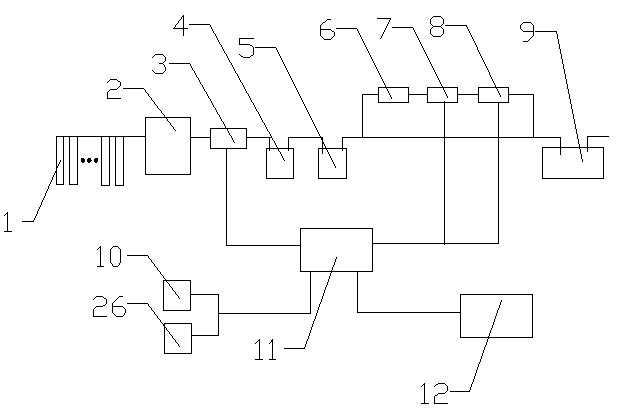

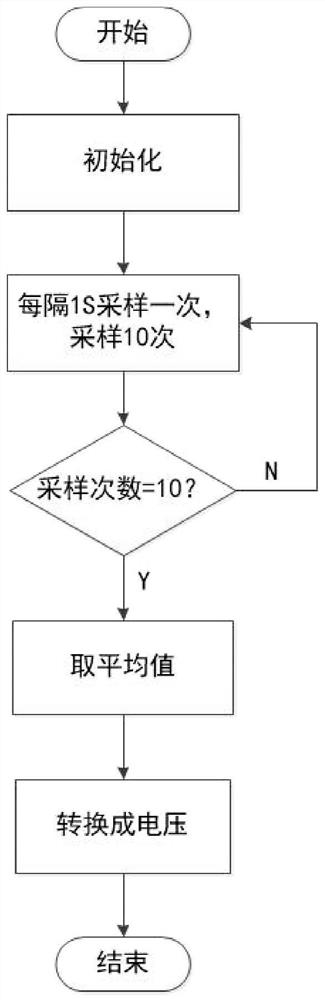

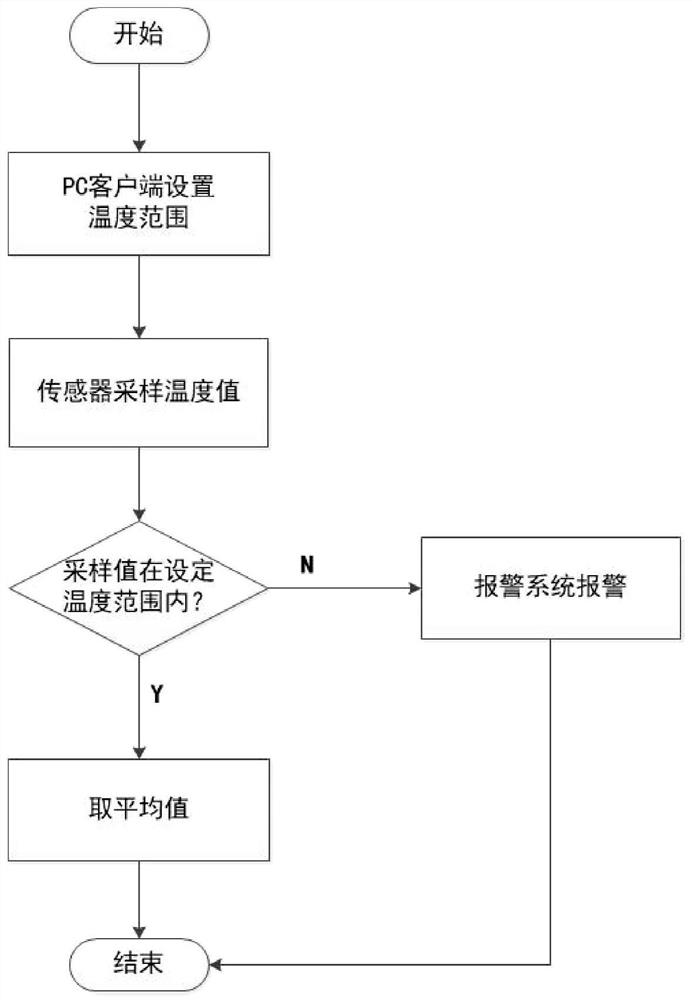

Integrated detection system of grain condition comprehensive index

The invention discloses an integrated detection system of a grain condition comprehensive index. The integrated detection system comprises a grain insect detection system and a granary temperature and humidity monitoring system which are respectively connected with a control module, wherein the control module is connected with an upper computer; the grain insect detection system comprises a plurality of insect capturing traps arranged at the different positions in a granary; each insect capturing trap is connected with a periodic strobe device driven by positive and negative motors through a connection pipe; the periodic strobe device is connected with an insect storing bottle through a connection pipe; the insect storing bottle is connected with a negative pressure source through a connection pipe; a compound gas monitoring system is connected on the connection pipe between the insect storing bottle and the negative pressure source in parallel. The integrated detection system disclosed by the invention can help a warehouseman to carry out comprehensive analysis judgment on a grain condition; the movement of insects in stored grains and the change condition of the grain condition in the granary can be tracked and monitored from all the directions in real time, so that the quality and the safety of the grains stored in the granary can be guaranteed.

Owner:ZHENGZHOU XINSHENG ELECTRONICS TECH

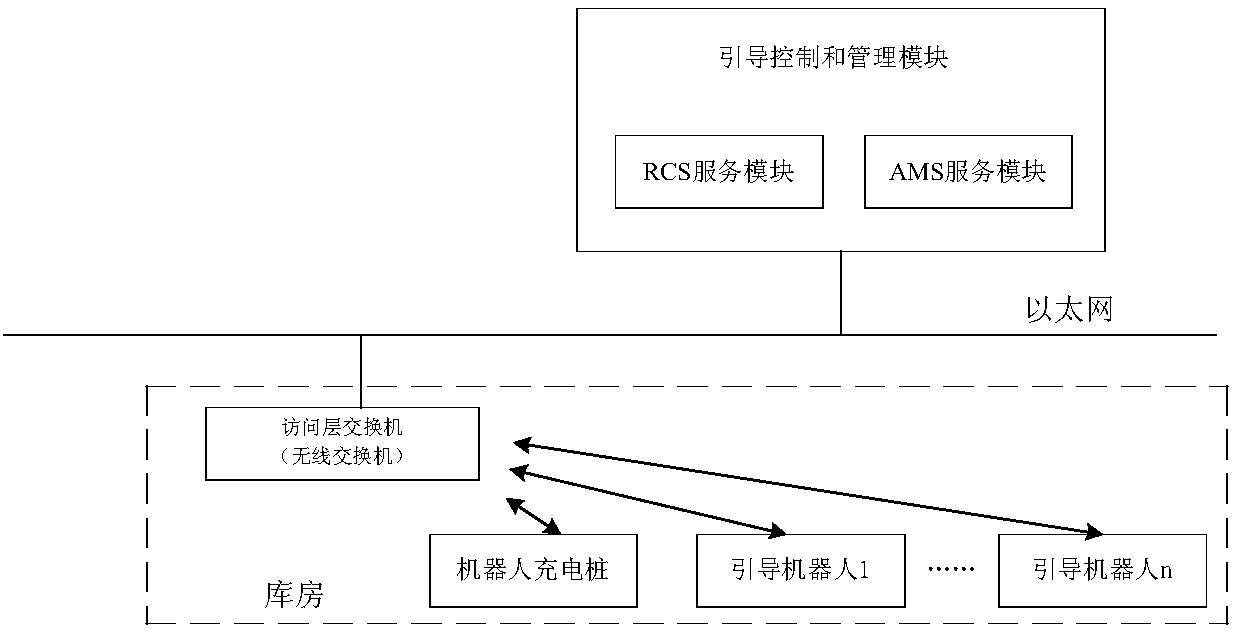

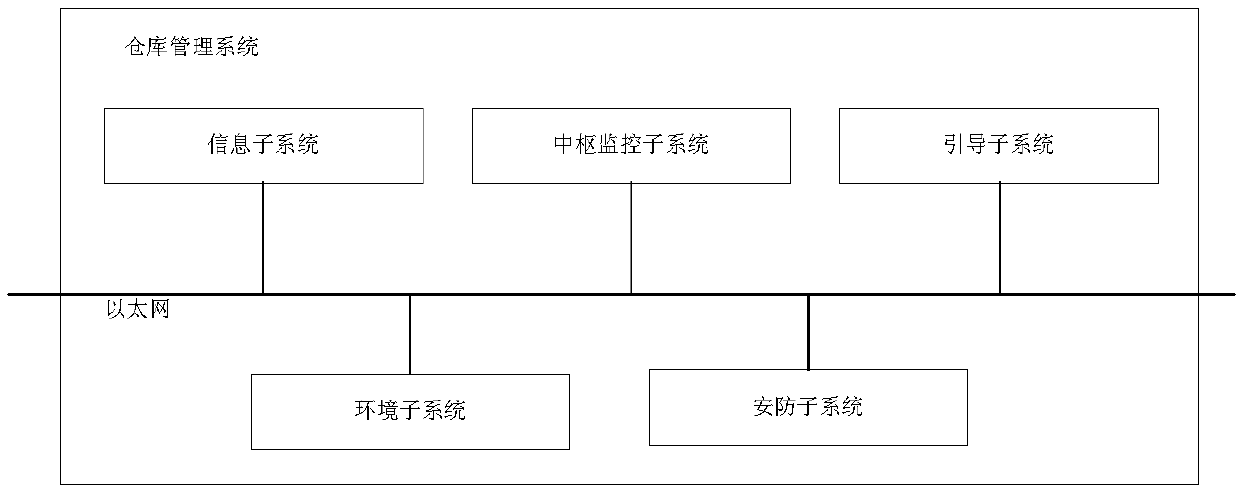

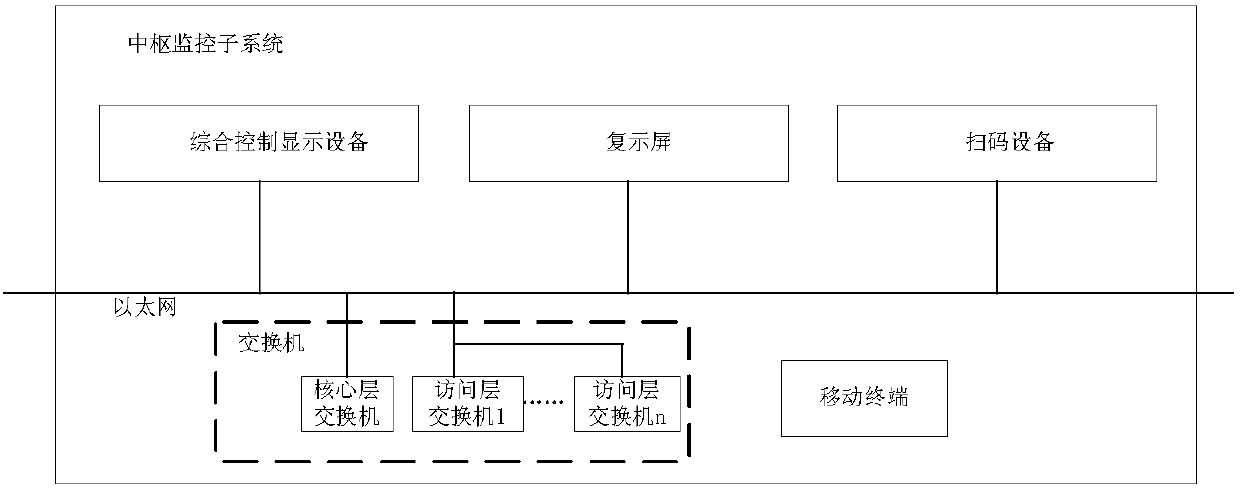

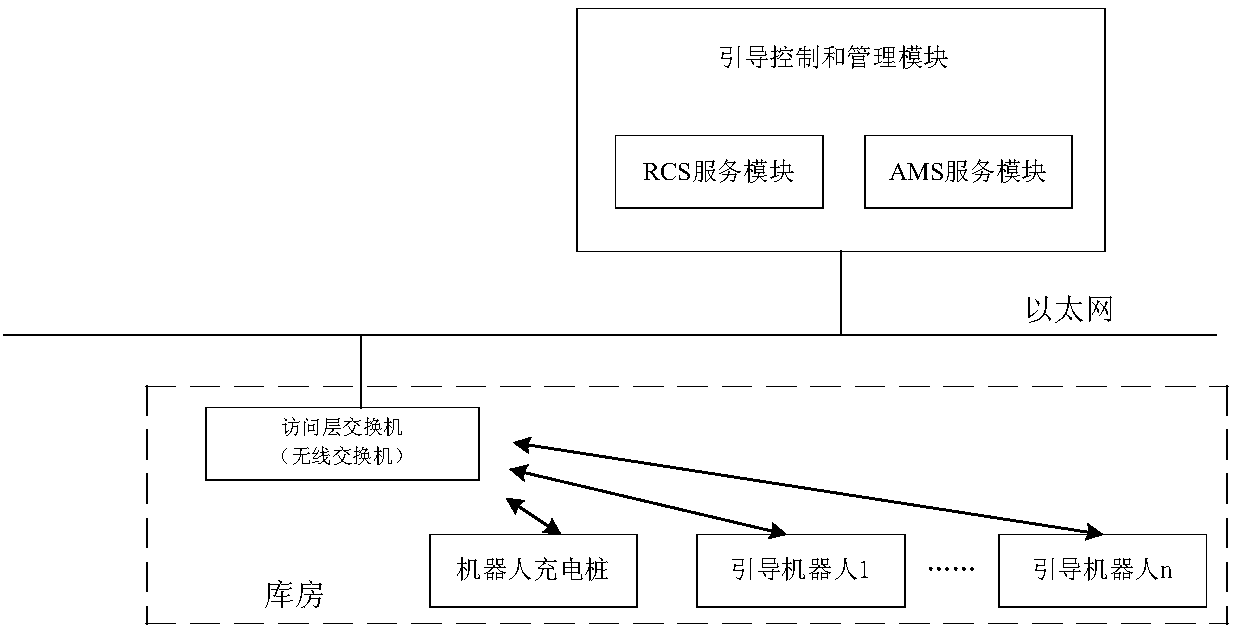

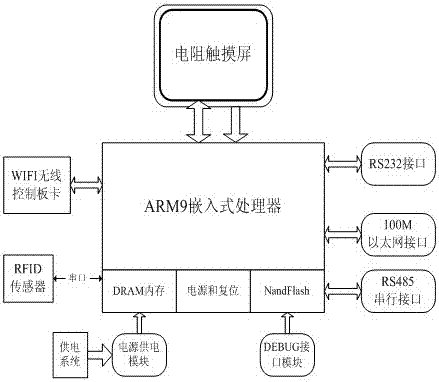

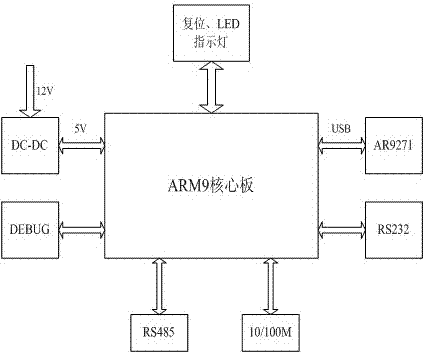

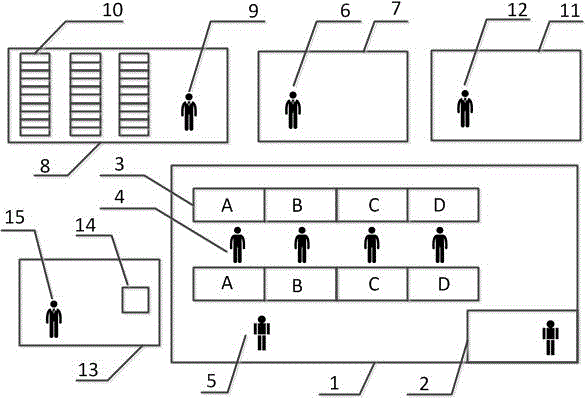

Intelligent warehouse management system based on guiding robot

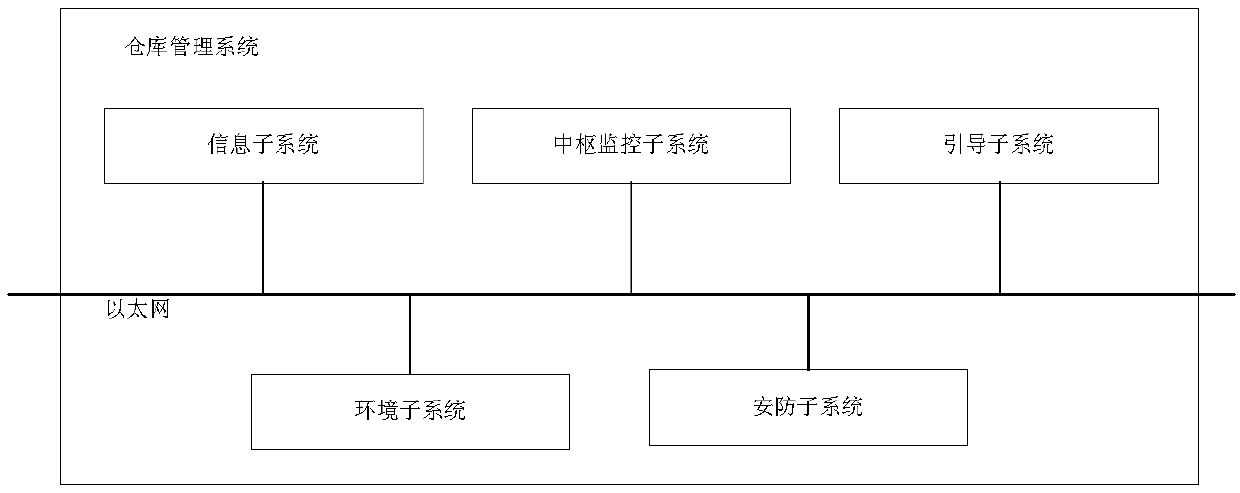

ActiveCN107679786AIntelligent linkage in and out of storageIntelligent linkage security monitoringLogisticsStorage devicesWarehousemanEthernet

The invention relates to an intelligent warehouse management system based on a guiding robot. The system comprises an information subsystem, a central monitoring subsystem, a guiding subsystem, a safety and protection subsystem and an environment subsystem. The subsystems are connected through the Ethernet. The intelligent warehouse management system informationizes equipment management of a warehouse, and out-put and in-put of warehouse of equipment, environment monitoring and safety and protection monitoring can be intelligently linked. An intelligent guiding robot is introduced, aiming at awarehouse demand, reconstruction is performed and the robot and an equipment management system realize integrated linkage. A mobile terminal is introduced and carries out mutual operation with the robot, and the equipment can be stored and taken out of the warehouse in real time. Aiming at characteristics that warehouse personnel is insufficient, new and old warehouse administrators alternate andthe new administrators are not familiar with services, the warehouse administrators are assisted to realize rapid out-put and in-put of warehouse; and through field testing, a required person numberis one third of that of the warehouse and time is shortened by nearly 50%.

Owner:CSSC ELECTRONICS TECH

Hazardous waste management system and method based on technology of Internet of Things

InactiveCN107368860AReduce the chance of exposureOvercome limitationsSustainable waste treatmentCo-operative working arrangementsMotor controllerEngineering

The invention relates to a hazardous waste management system based on the technology of Internet of Things, and the system mainly consists of an RFID reading-writing module, a stepping motor controller, a driver, a synchronous belt sliding table and an upper computer system. The stepping motor technology is used on a synchronous sliding table, thereby forming a precise positioning device. The device is fixed at the bottom of a chemical shelf, and is combined with the RFID reading-writing module. The device precisely locates the placing position of chemicals in an operation process, and the storage state information of chemicals is obtained through the reading-writing module. The system makes contact with a hardware part through a ZigBee network, and operates the precise positioning device and the RFID reading-writing module. The system has a function of data management, and a manager can query the information, parameters and various indexes of chemicals in a warehouse. The system is advantageous in that the system overcomes the limits caused by the application of the single technology, enables the application range of the RFID technology to be extended, and greatly reduces the probability that a warehouse manager makes contact with dangerous chemicals, and reduces the potential safety hazards.

Owner:江苏汇环环保科技有限公司

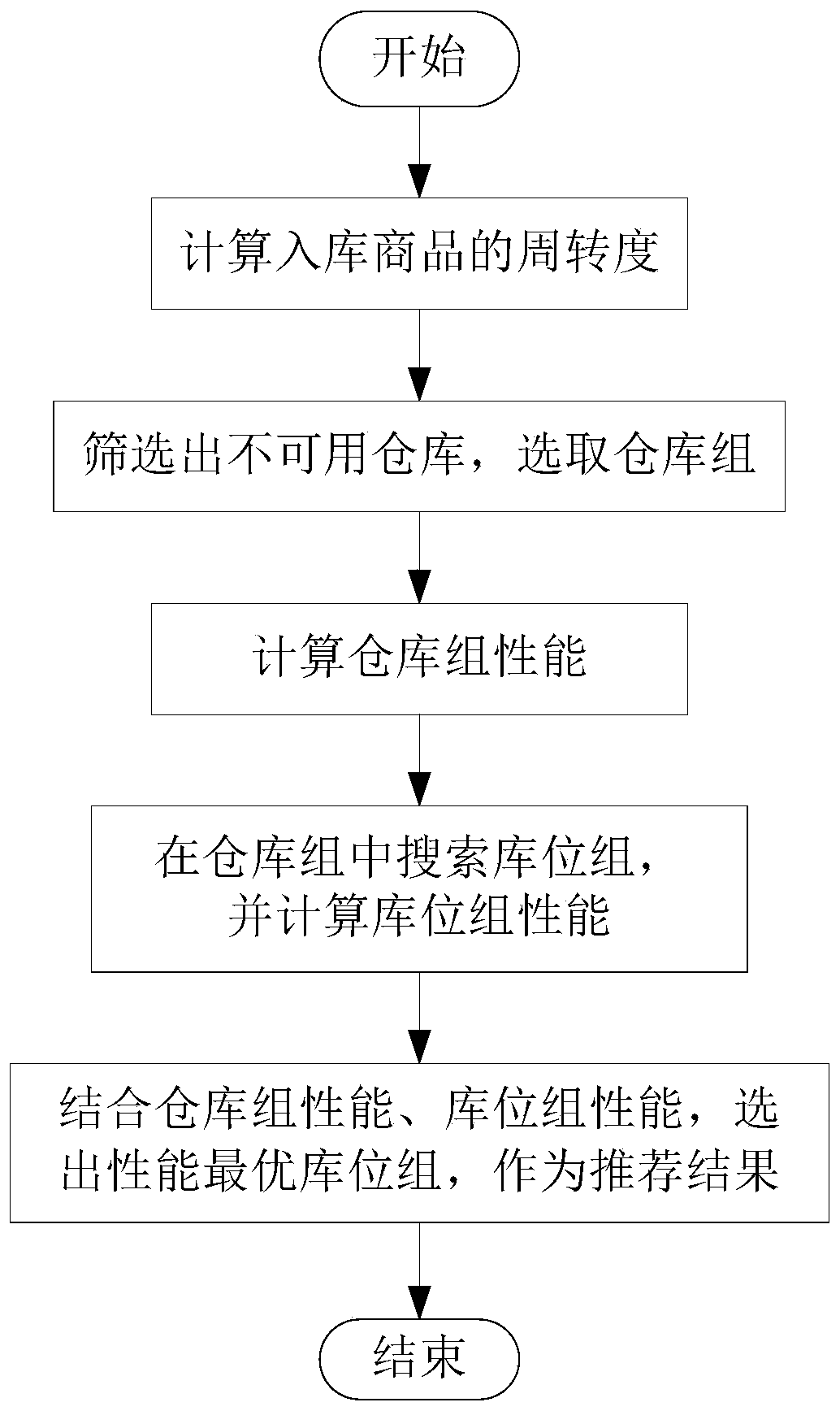

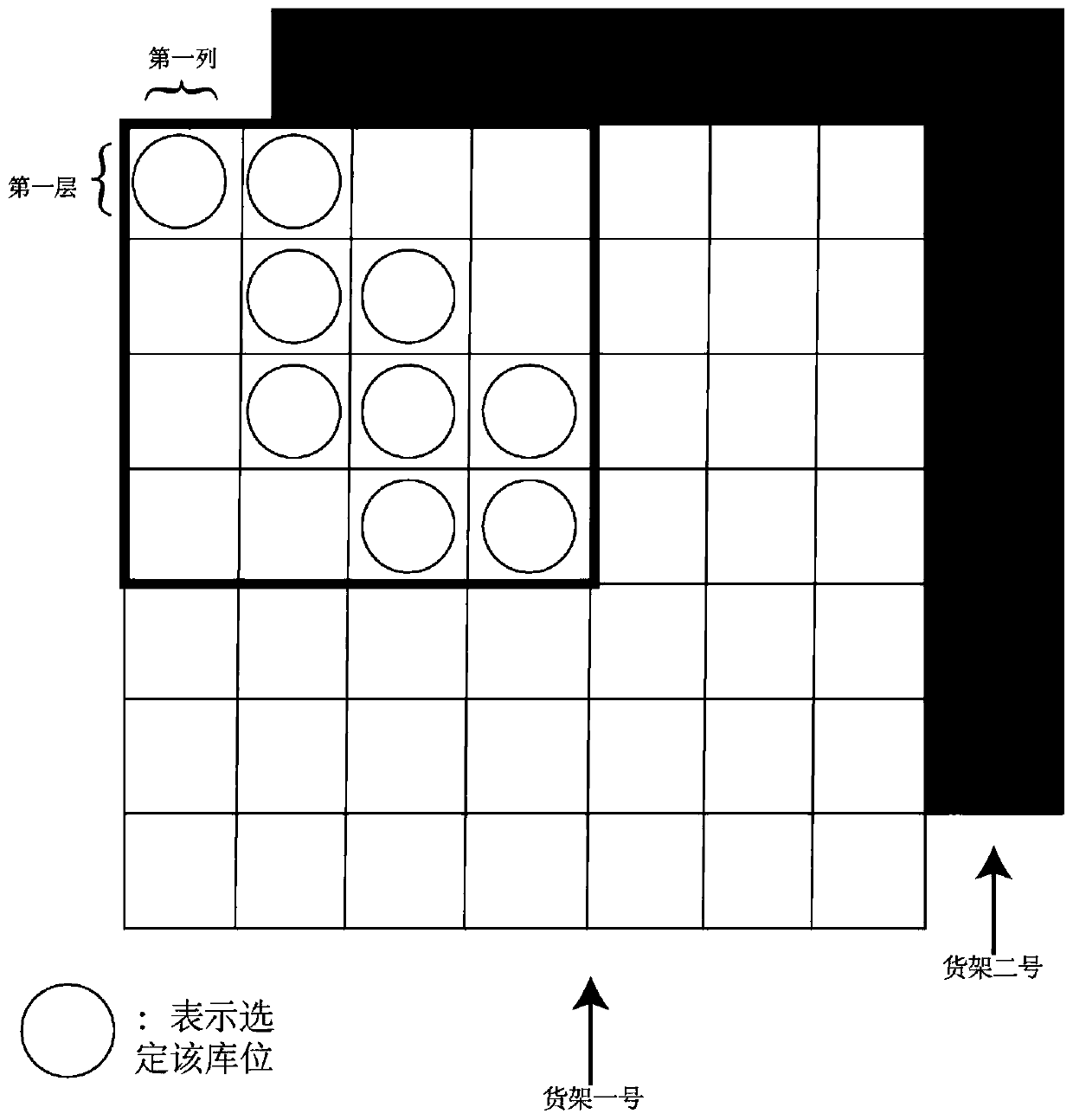

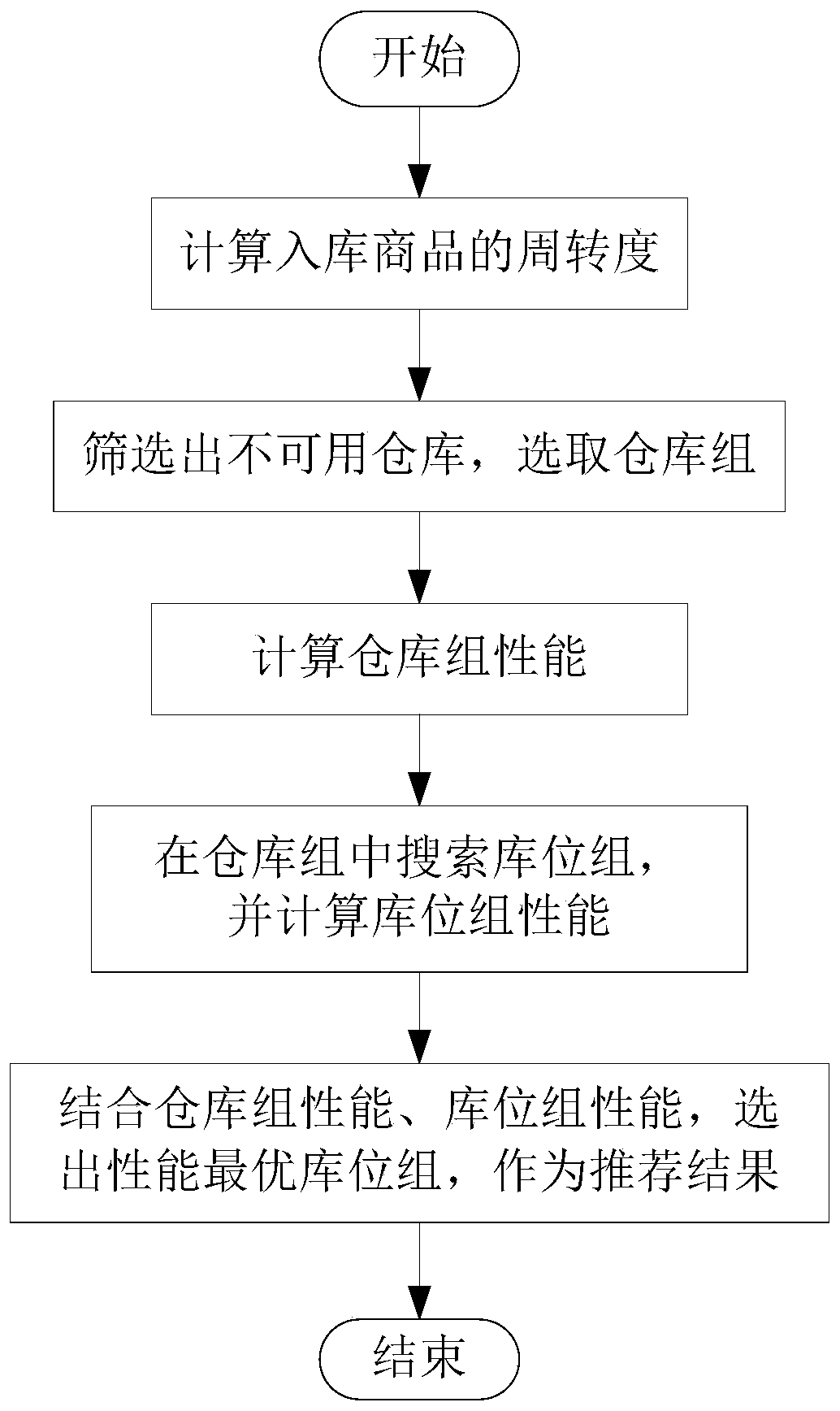

Warehouse cargo warehousing method

The invention discloses a warehouse goods warehousing method. The warehouse goods warehousing method comprises the following steps that S1, the turnover degree of warehoused goods is calculated; s2, unavailable warehouses in the district are screened out, a certain number of warehouses are selected from the screened available warehouses to form a warehouse group, and the performance of the warehouse group is calculated; s3, a storage location group is searched in the warehouse group, and the performance of the storage location group is calculated; and S4, by combining the warehouse group performance and the storage location group performance, the storage location group with the optimal performance is selected as a recommendation result. According to the invention, a proper storage locationis selected according to the characteristics of fluidity, vulnerability and the like of a commodity; and the warehouse location storage scheme with low dispersion degree is calculated and selected, so that the utilization rate of warehouse locations can be greatly improved, the condition of fragmented warehouse locations of warehouses is reduced, the time of manual operation during later warehouse management is reduced, warehouse managers can conveniently manage commodities, and the economic benefit is improved.

Owner:SICHUAN HONGTU LOGISTICS +1

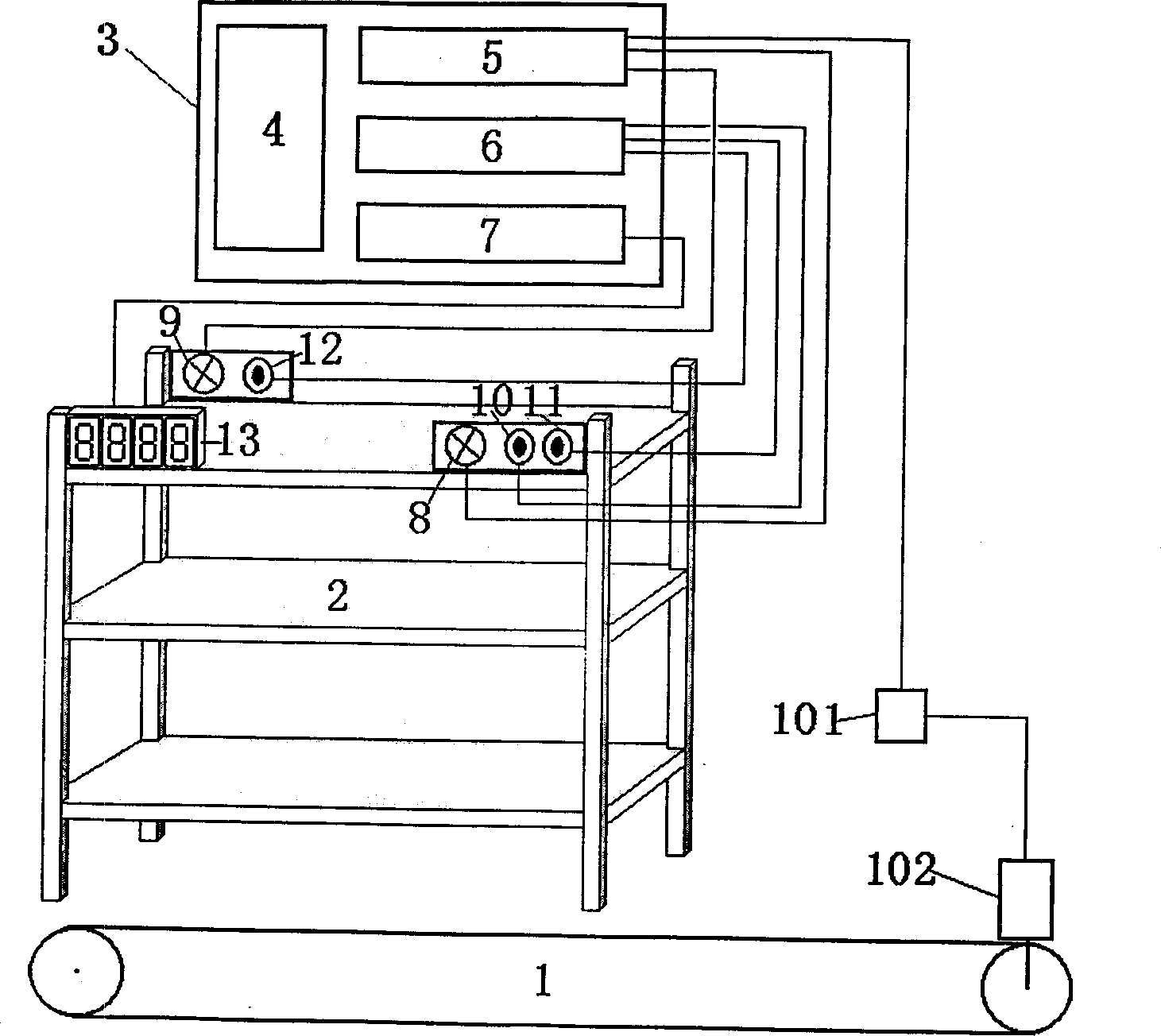

Distribution system for cigarette distributing center

InactiveCN1373079AStrengthen distribution capacityReduce labor intensityStorage devicesMicrocomputerDistribution system

A distribution system for cigarette distributing center is composed of cigarette conveying unit, shelf unit with goods inducator, supply button and digital display module for each shelf, and computercontrol unit consisting of microcomputer, I / O module and digital display driver module. The cigarette brands on lading bill are decomposed to relative shelves by said computer control unit. If some brand is absent on its shelf, its absent button is pressed by worker to inform the storage manager and the brand of cigarettes is conveyed from storage to the shelf while its absent indicator is turnedoff. Its advantages are high productivity and correctness, and saving labour.

Owner:浙江中溢科维信息技术有限公司

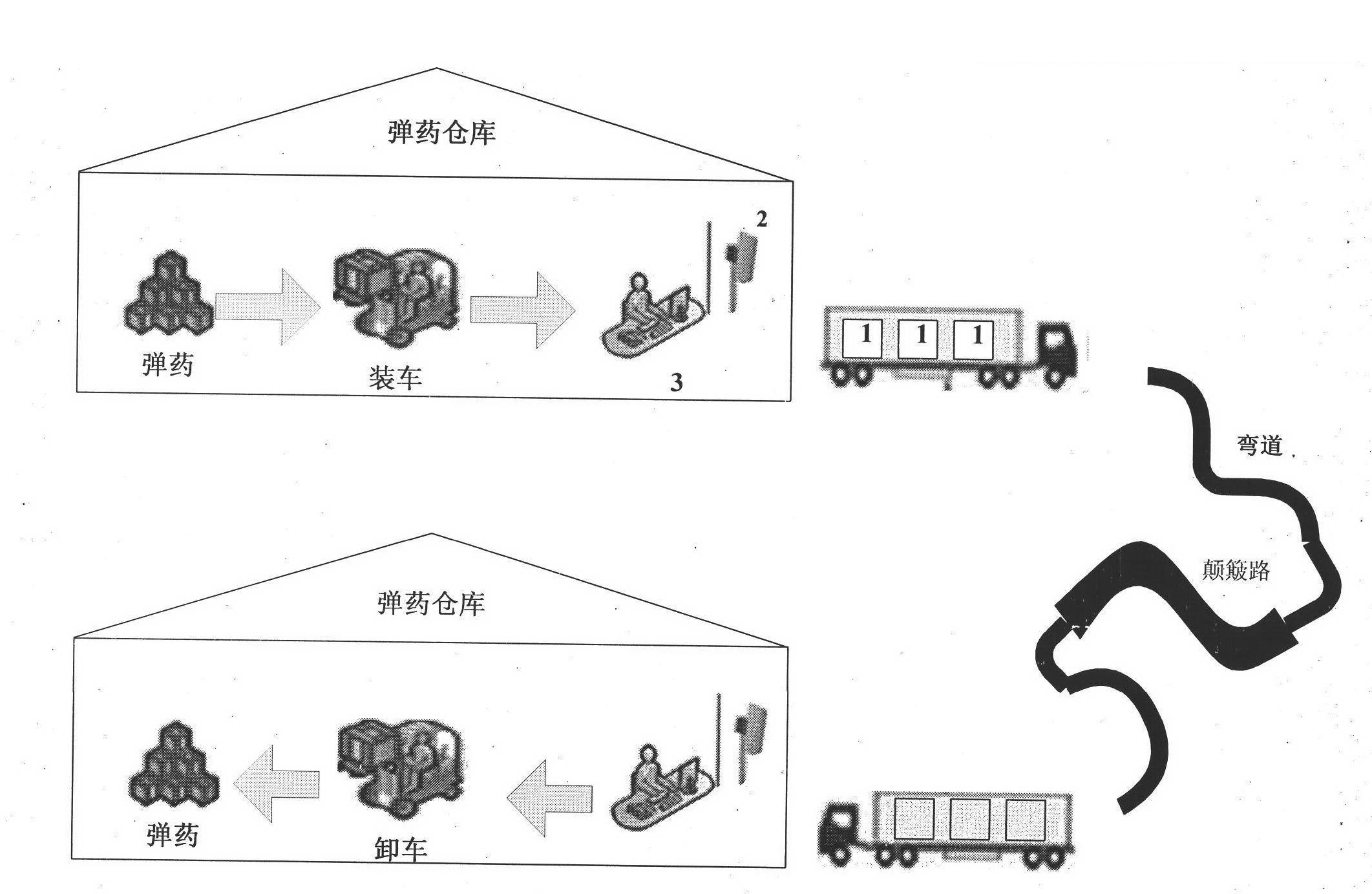

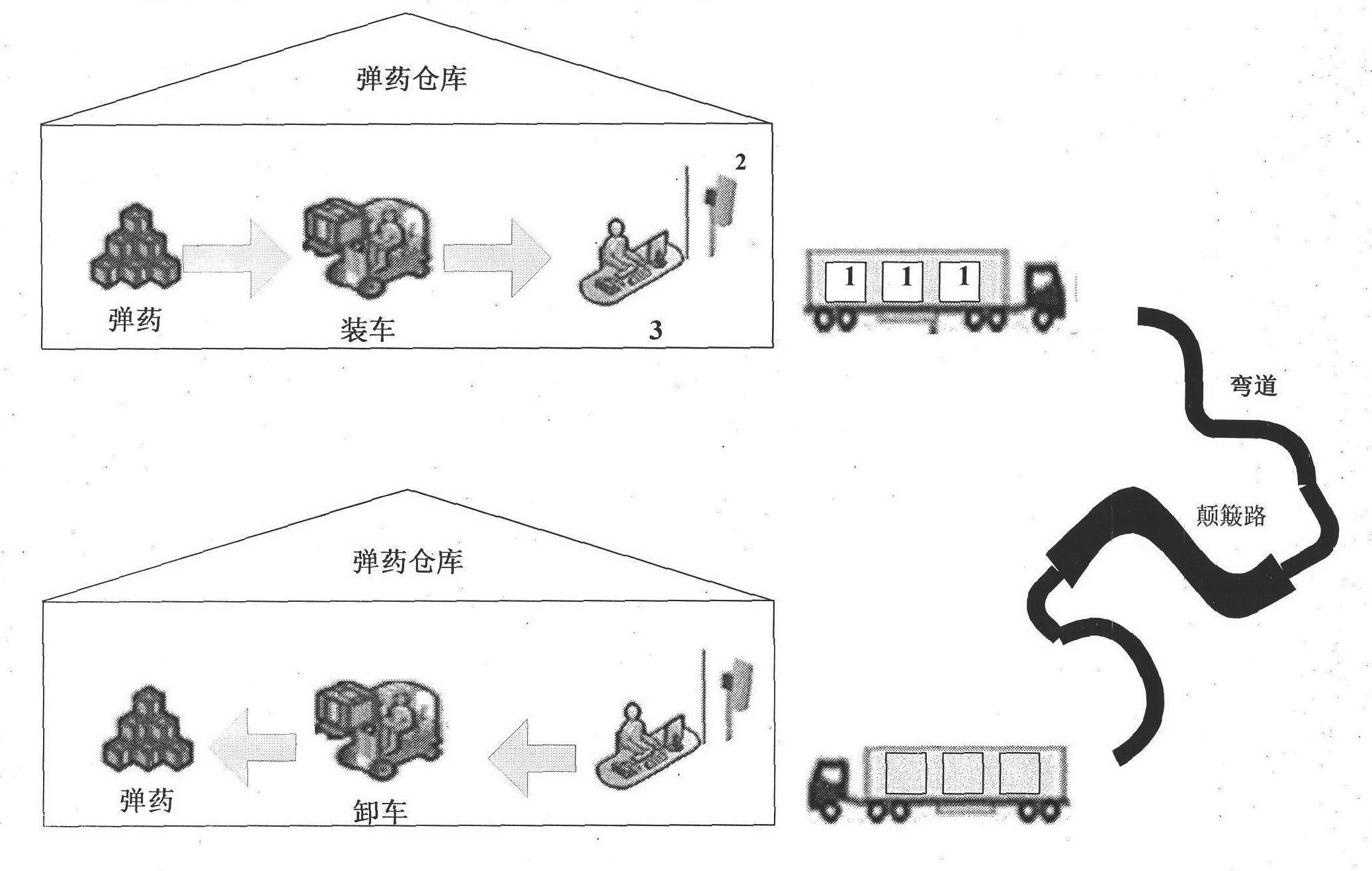

Method for monitoring and intelligent management of ammunition storage and transportation

InactiveCN102254252AImprove management efficiencyData processing applicationsDriver/operatorSecure state

The invention discloses a method for monitoring and intelligent management of ammunition storage and transportation, wherein an ammunition physical-state information acquisition terminal is mounted in an ammunition packing container so as to monitor the physical states of the ammunition and record an acceleration, a temperature and a humidity each exceeding respective thresholds and the moments corresponding to the occurrence of such events in real time, and give alarm information for a driver or a warehouse keeper and store the alarm information in the memory of the acquisition terminal; next, logistics information and a unique Identification (ID) number stored in the ammunition physical-state information acquisition terminal are read through a warehouse gate monitoring system when ammunition is passed in and out of a warehouse; if an alarm event is present, the information of the alarm event is read and an alarm is given to prompt the unsafe state of the ammunition, and simultaneously, the logistics information and the physical state information of the ammunition are uploaded to an ammunition storage management platform in real time; moreover, the ammunition storage management platform is employed to check the in-out records of the ammunition and modify the database of the warehouse; and then the obtained state information is drawn into a curve according to a time correspondence relationship for the visual reference of the users.

Owner:娄文忠

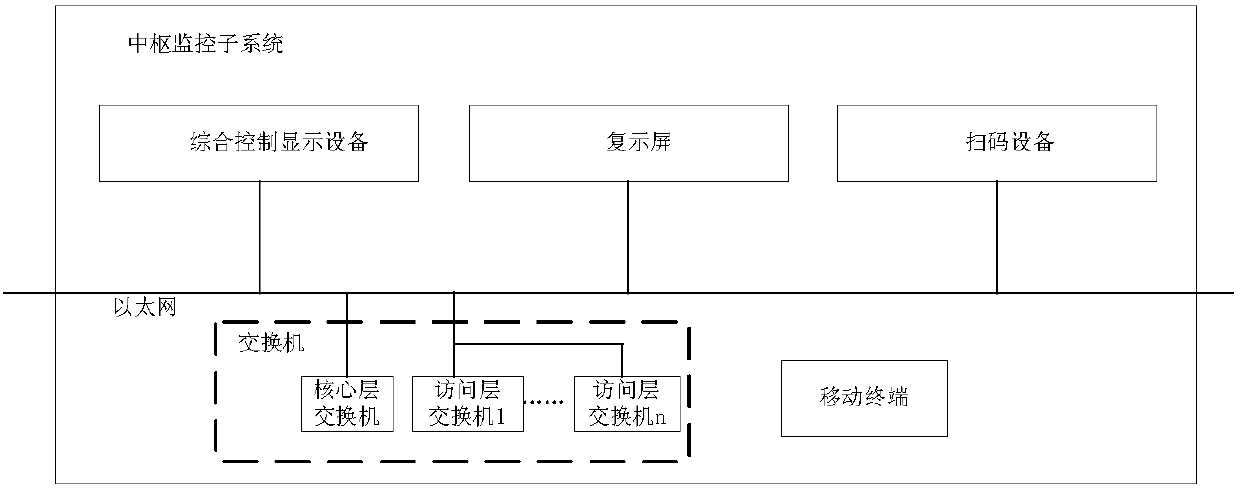

Intelligent warehouse management method based on central monitoring

ActiveCN107705058AIntelligent linkage in and out of storageIntelligent linkage security monitoringCo-operative working arrangementsIndividual entry/exit registersMonitoring systemField tests

The invention relates to an intelligent warehouse management method based on central monitoring. A central monitoring system for the intelligent warehouse finishes delivery, storage and inventory tasks under the assistance of a guidance robot for an operator according to a user request. The intelligent warehouse management method enables the device management of the warehouse to be informatized, the device can be intelligently linked to be delivered and stored to realize environment monitoring and security and protection monitoring; the intelligent guidance robot is imported, transformation iscarried out by aiming at the requirements of the warehouse, and integrated linkage is realized with the device management system; a mobile terminal is imported to mutually operate with the robot, andthe device can be delivered and stored in real time; and by aiming at the characteristic that warehouse personnel are in shortage, new and old warehouse managers alternately work and personnel are not familiar with business, the warehouse managers can be assisted in quickly carrying out delivery and storage, a field test proves that the amount of required personnel is 1 / 3 of the amount of an original warehouse, and time is shortened by about 50%.

Owner:CSSC ELECTRONICS TECH

AGV wireless centralized control device and method

InactiveCN107229249AEasy to monitorStable and convenient communicationTransmission systemsNetwork topologiesData terminalData information

The invention discloses an AGV wireless centralized control device and an AGV wireless centralized control method. The AGV wireless centralized control device comprises a WIFI data terminal, a data concentrator and a centralized control center. The AGV wireless centralized control device stores and plans corresponding AGV routes in real time according to data information reported by the WIFI data terminal so that the whole system reaches the highest working efficiency, and mainly realizes the functions of providing a visual display interface for a warehouse manager and facilitating the worker to monitor corresponding information such as AGV motion states, material shortage and material usage in real time.

Owner:NANJING INST OF TECH

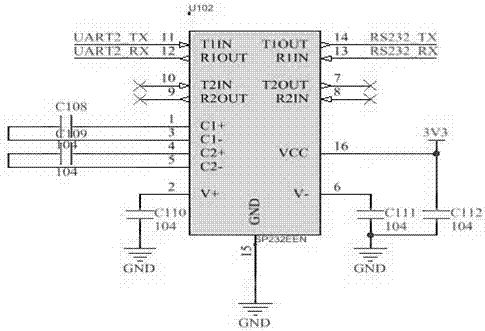

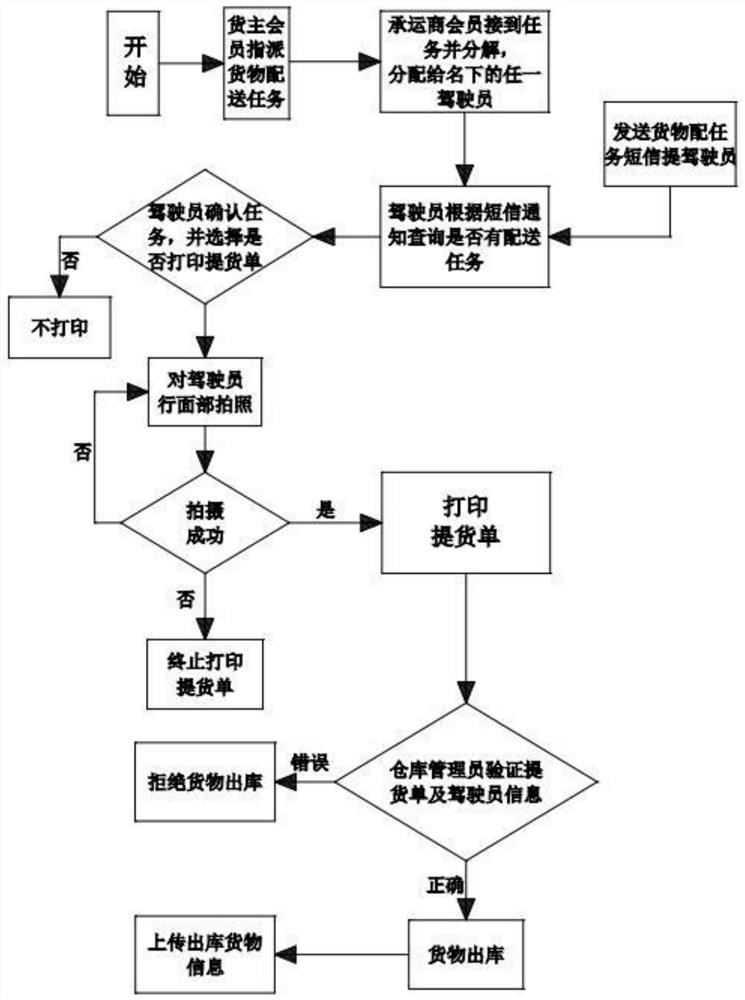

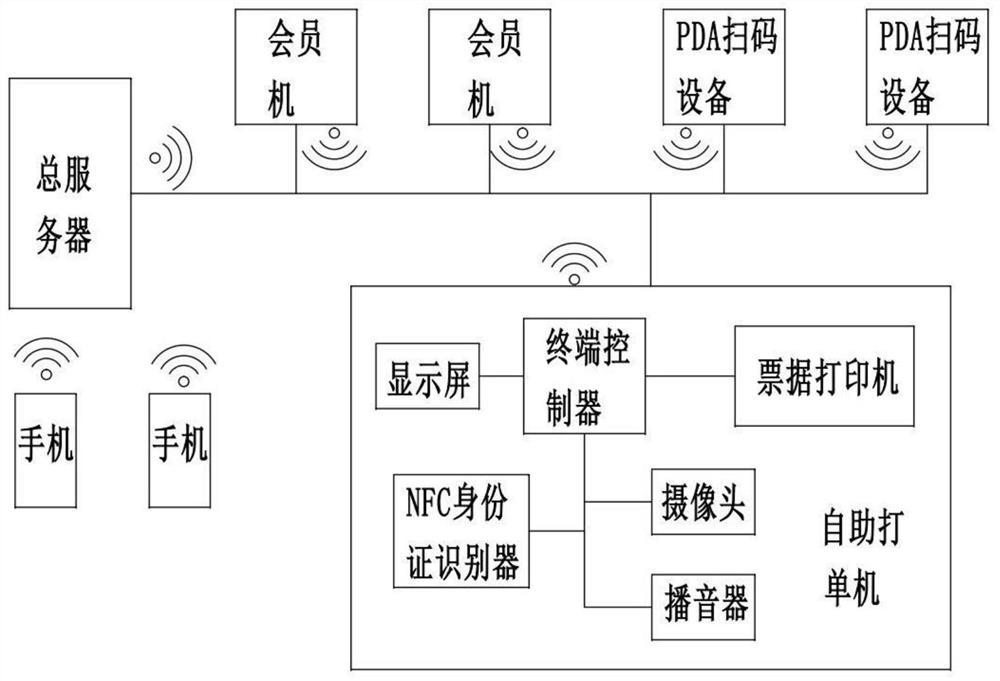

Shipment self-service bill printing method and bill printing system based on Internet of Things technology

PendingCN111815269APrevent forgeryGuaranteed identity authenticityOffice automationLogisticsLogistics managementThe Internet

The invention discloses a shipment self-service bill printing method based on the Internet of Things technology. The shipment self-service order printing method comprises the steps that member basic information maintenance is performed; a member performs business collaboration through an intelligent cloud warehouse; a driver performs bill printing through self-service; a warehouse administrator performs code scanning for verification; and cargo warehouse-out processing is performed. The shipment self-service bill printing system based on the Internet of Things technology comprises a set of intelligent cloud warehouse management system, at least one main server, at least one self-service bill printing machine, at least one member machine and at least one PDA code scanning device. The intelligent cloud warehouse management system is installed in the total server, the member machine and the self-service bill printing machine. The total server is in wired or wireless signal transmission connection with the member machine, the self-service bill printing machine and the PDA code scanning device. The shipment self-service bill printing method and system combines the logistics cloud warehouse platform with the Internet of Things technology, and on the basis of real services and data of the logistics cloud warehouse platform, completes identity authentication of a driver and auditing ofreceipts through the Internet of Things technology, so that the service operation efficiency of a logistics park is improved on the premise that safety is guaranteed.

Owner:YUNNAN KUNGANG ELECTRONICS INFORMATION TECH CO LTD

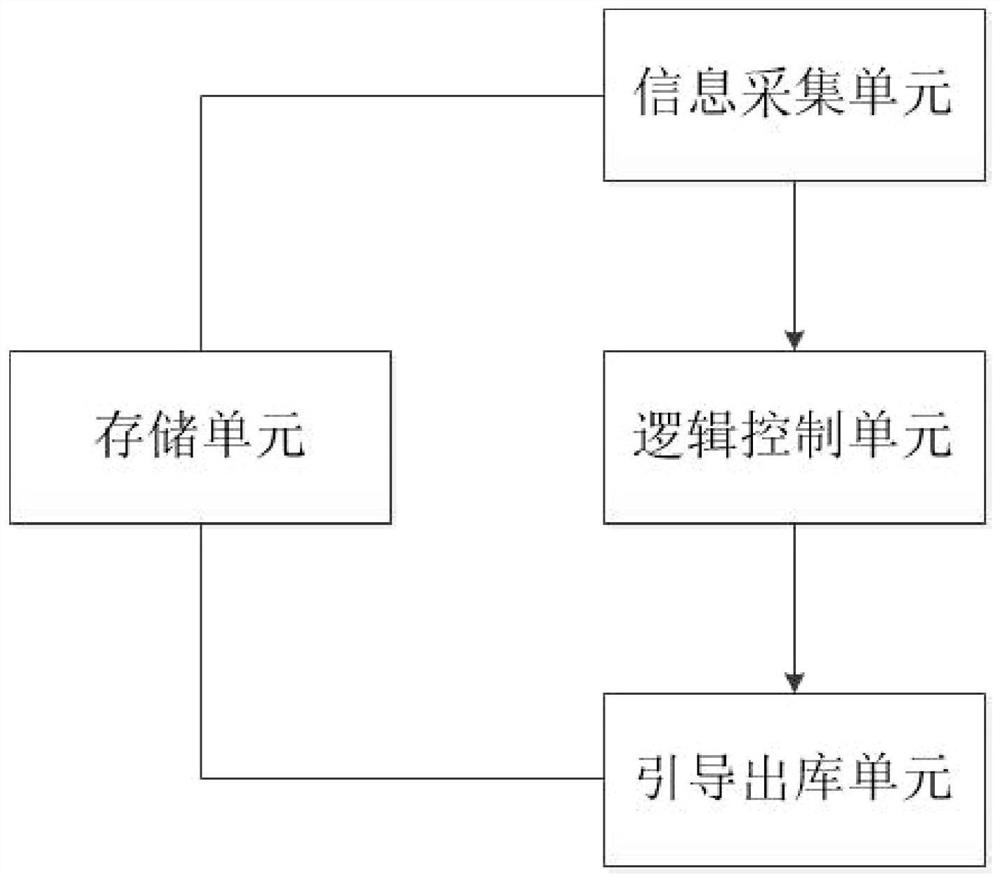

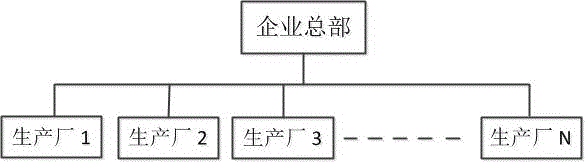

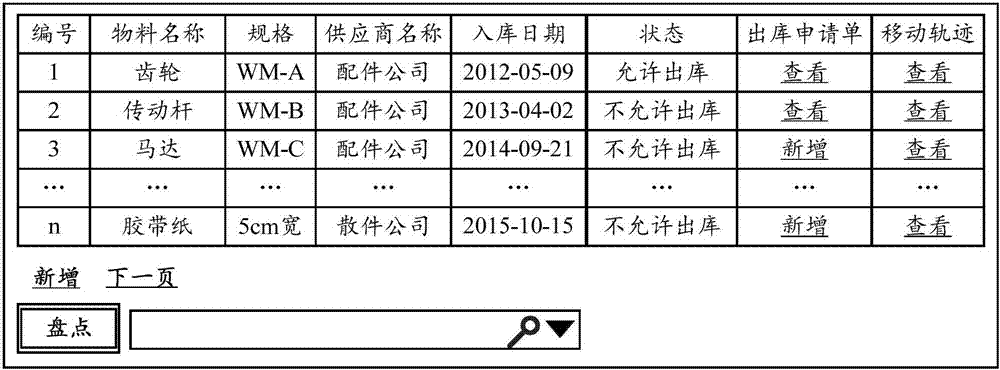

Material management system and management method

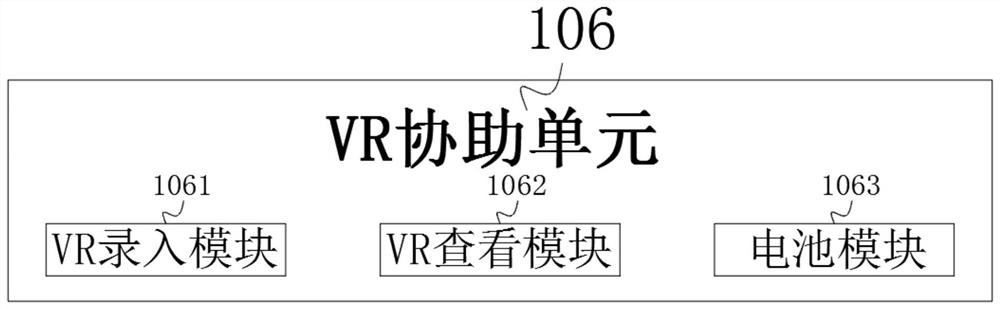

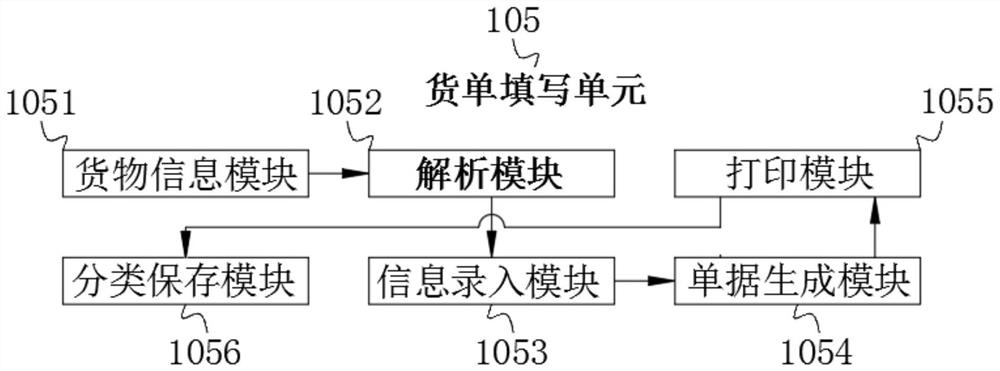

PendingCN113487177AEasy to manageQuality improvementCo-operative working arrangementsResourcesWarehousemanMaterials management

The invention relates to a material management system and a management method. The information acquisition unit acquires material associated data and uploads the acquired data; the storage unit stores the data uploaded by the information acquisition unit; the warehouse-out guiding unit is used for positioning the position of the material in the warehouse, so that a warehouse administrator can quickly take out the matched material; and the logic control unit measures the material quality and the management quality in the warehouse based on the acquired data. According to the invention, the materials conforming to the shelf life can be automatically screened out according to the shelf life of the materials provided by the client, so that the performance of the products in the specified shelf life is in the best state, the quality of the products is improved, the material quality and management quality of the whole warehouse are measured according to the service life of the materials of the whole warehouse, and the management of enterprises on warehouse management quality and operation efficiency is improved.

Owner:杭州晶志康电子科技有限公司

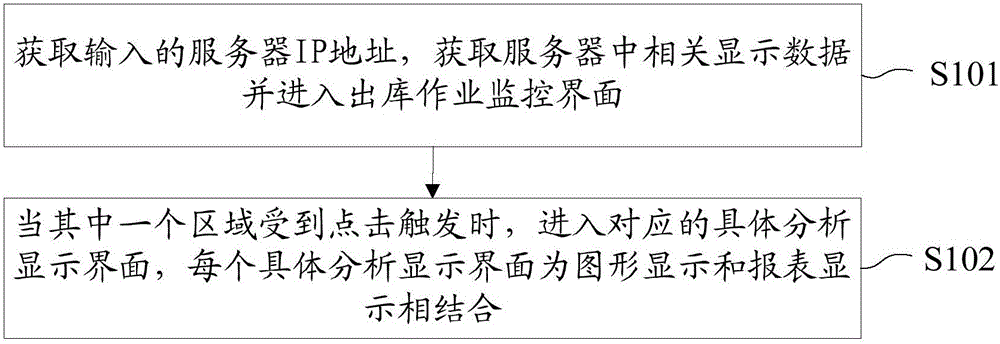

Warehouse-out operation monitor method and system

The invention is suitable for the technical field of logistics management and provides a warehouse-out operation monitor method and system. The method comprises steps of obtaining an input IP address of a server and related display data in the server, and entering a warehouse-out operation monitor interface; and when some region is subjected to click trigger, entering a corresponding concrete analysis display interface, wherein each concrete analysis display interface is the combination of figure display and report display. According to the invention, each monitor region adopts a display mode of combining figures with reports; data display is performed from four dimensions of progress of warehouse-out operation, working conditions of operation regions, conditions of abnormal tasks and personal operation conditions; warehouse managers can conveniently and rapidly find out orders with problems, operation links of blocking progress of warehouse-out operation, links with low warehouse-out operation efficiency; and the reference basis is provided for warehouse managers for reasonably deploying warehouse-out operation resources.

Owner:HUBEI JOINTOWN TECH

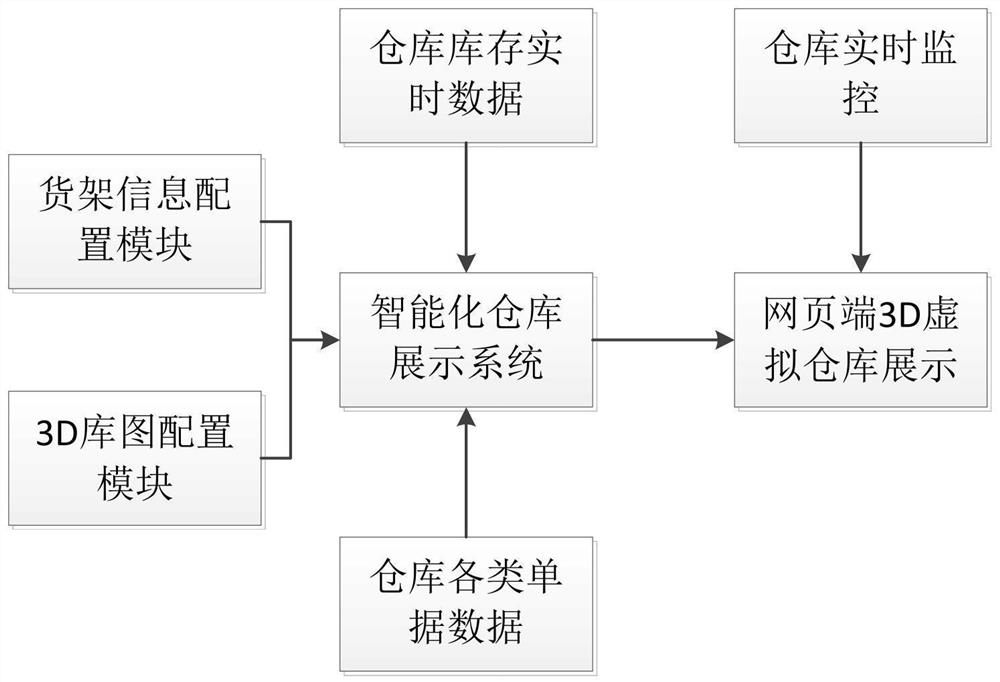

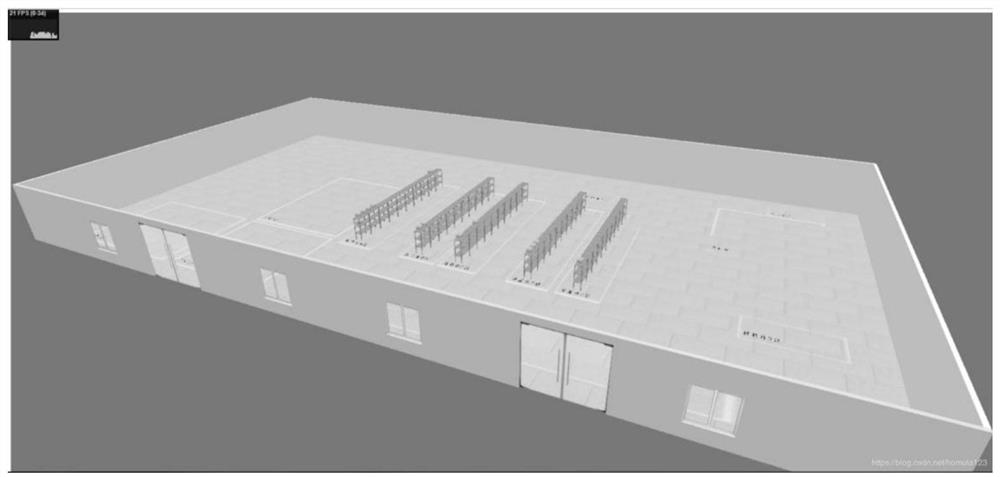

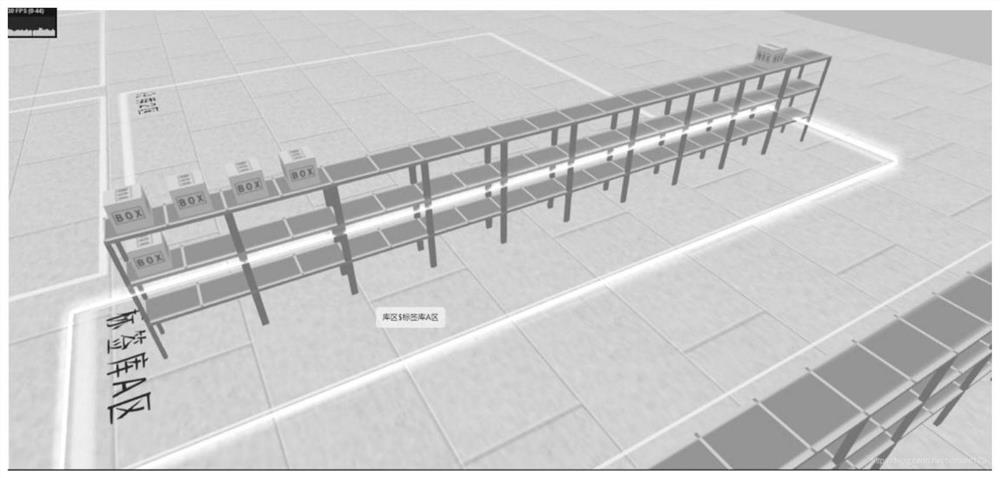

Intelligent warehouse system based on webpage end 3D technology

PendingCN113515714AEasy to viewSimplify business operationsWebsite content managementLogisticsInformation repositoryReal-time data

The invention provides an intelligent warehouse system based on a webpage end 3D technology. The system comprises: a goods shelf information configuration module which configures goods shelf information in a warehouse; a 3D library graph configuration module which is used for carrying out content configuration on a 3D library area, a 3D goods shelf and a scene; a 3D virtual warehouse data collection module which is used for collecting warehouse stock real-time data and warehouse in-out receipt data; and a 3D virtual warehouse display module which is used for viewing the 3D virtual warehouse in the 3D virtual warehouse display picture. According to the system, the 3D virtual warehouse can be displayed on the browser according to dynamic configuration, a warehouse administrator or a leader can visually check various information of the warehouse conveniently, simple service operation can be visually carried out on the 3D virtual warehouse, the 3D virtual warehouse is combined with a real-time monitoring picture, and the details of the warehouse can be known more comprehensively.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Management method, device, terminal and system for warehouse packaging table

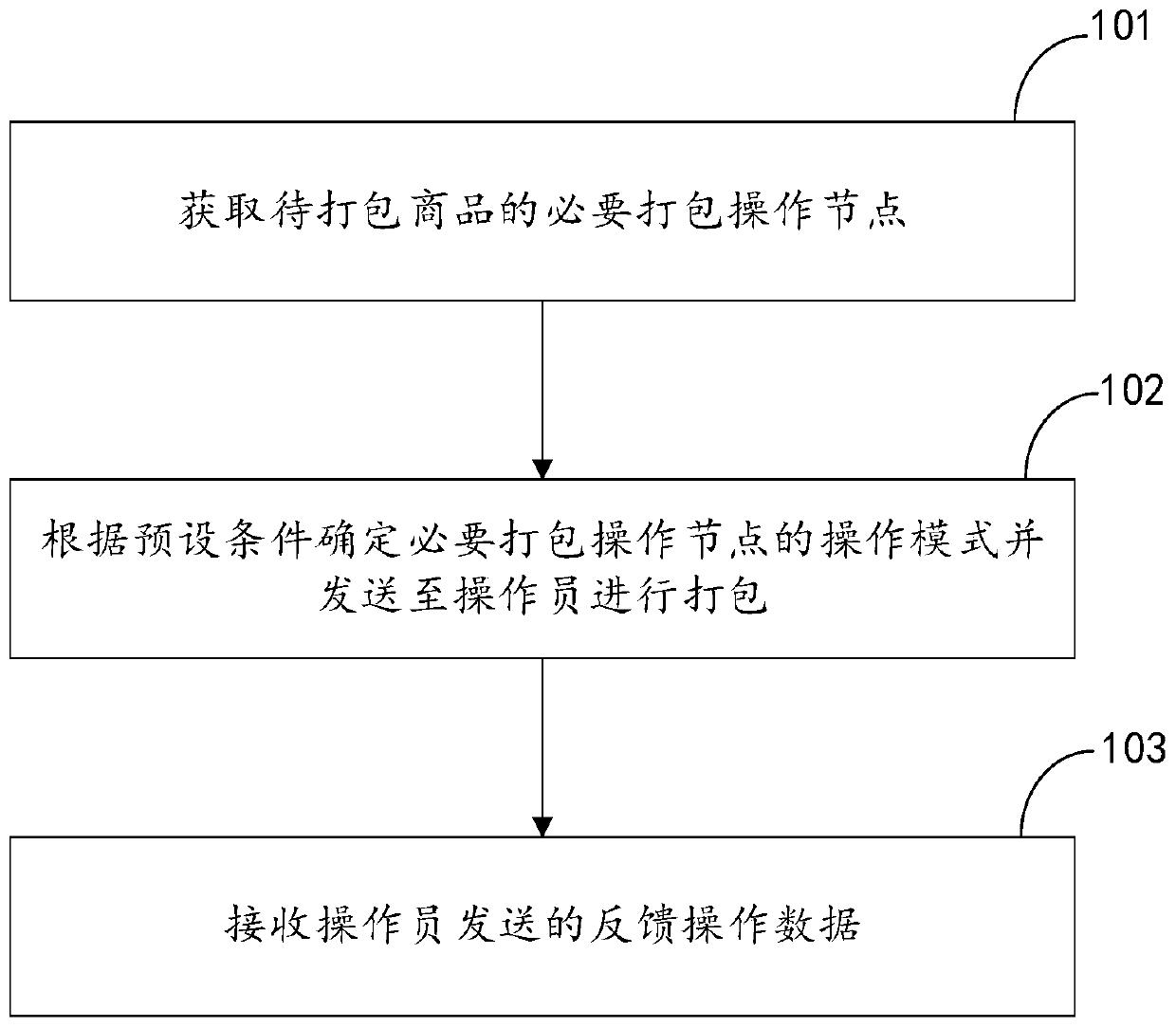

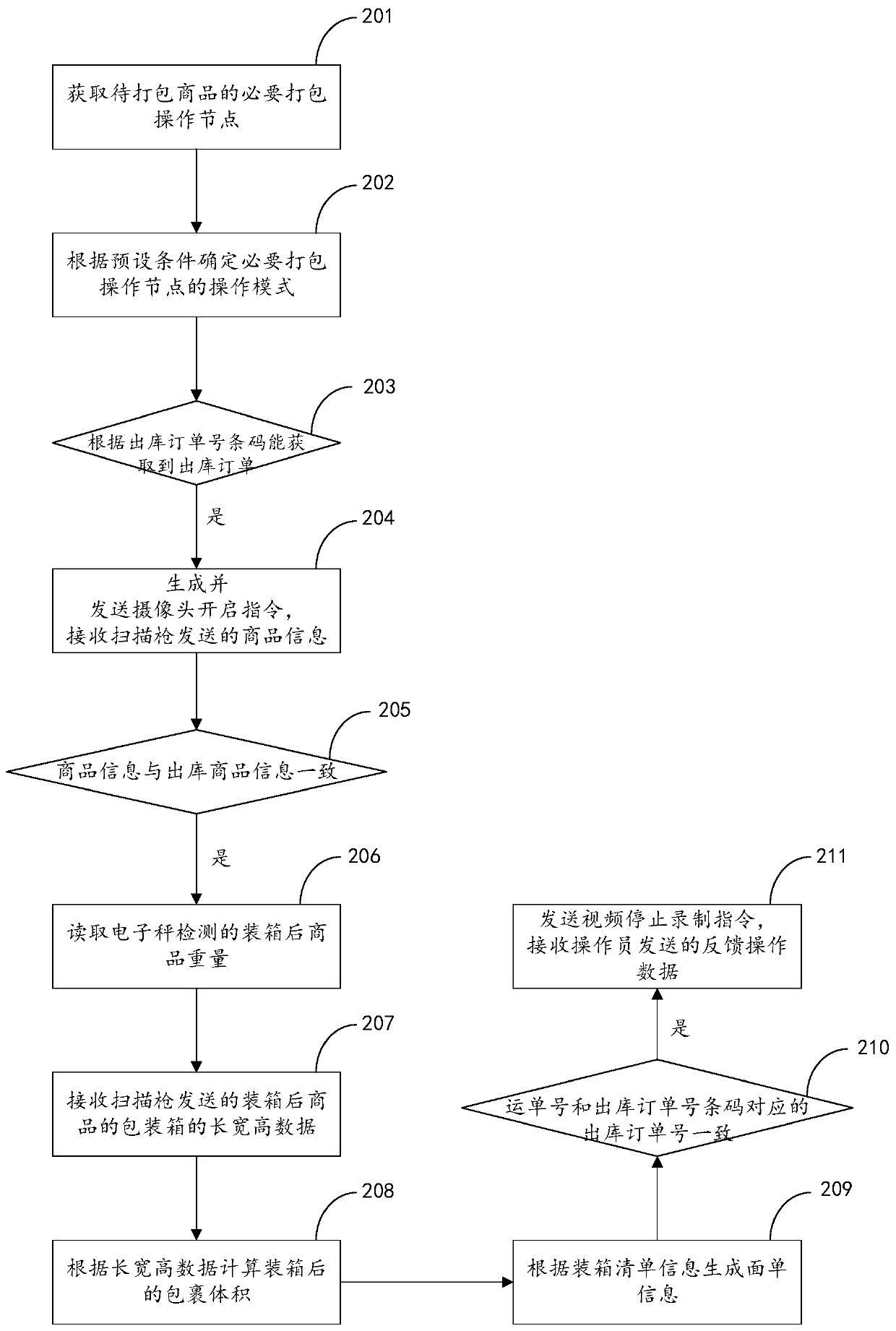

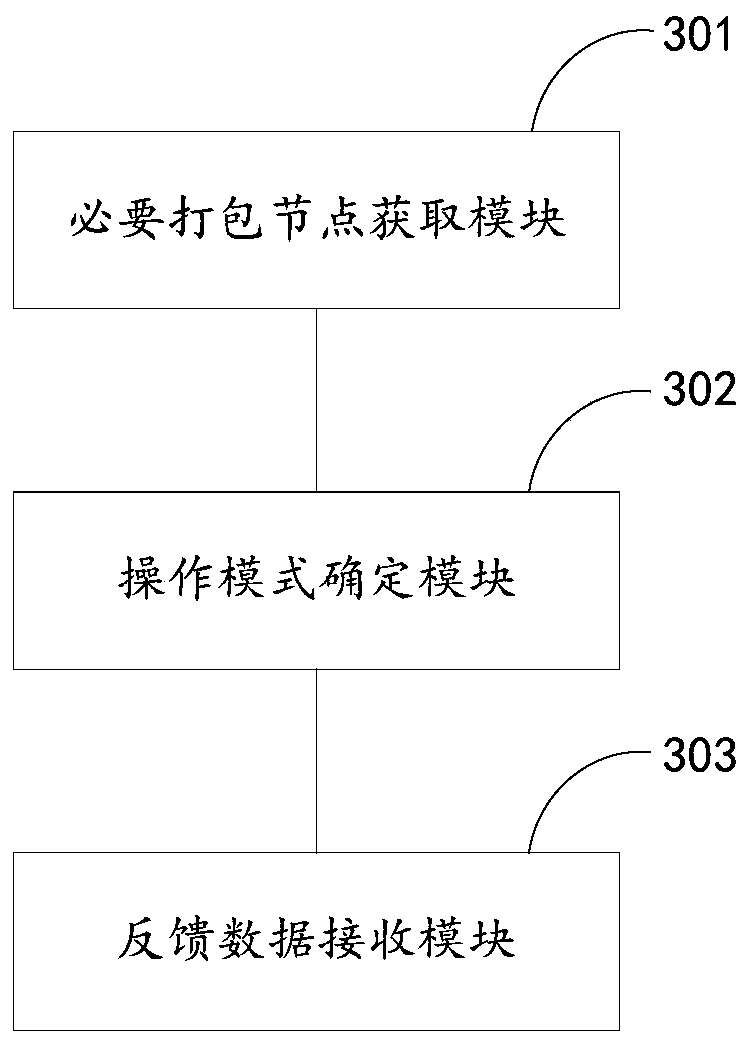

PendingCN110322202AImprove operational efficiencyLogisticsManufacturing computing systemsResource utilizationApproaches of management

The invention relates to a warehouse packaging table management method, device, terminal and system. The method comprises the steps of acquiring necessary packaging operation nodes of to-be-packaged commodities; wherein the necessary packaging operation nodes are determined by a warehouse administrator according to warehouse conditions; wherein the necessary packaging operation nodes comprise a boxing rechecking node, a weighing node, a material scanning node, an order printing node and / or an order pasting node; determining an operation mode of the necessary packaging operation node accordingto a preset condition and sending the operation mode to an operator for packaging; wherein the preset condition is set according to the acquired actual situation of the warehouse; wherein the operation mode is formed by combining a set number of necessary packaging operation nodes; and receiving feedback operation data sent by the operator. By adopting the method, the device, the terminal or the system, the operation mode can be flexibly configured according to the actual situation of the warehouse, so that human efficiency and resource utilization are more reasonable and controllable.

Owner:SHANGHAI ZHONGTONGJI NETWORK TECH CO LTD

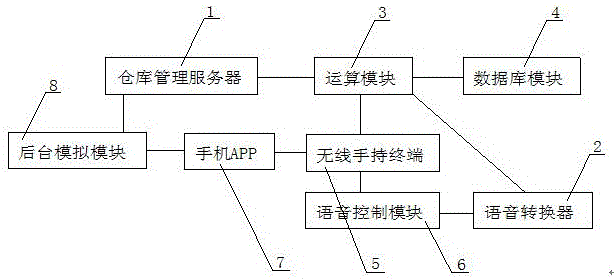

Warehouse management system

The invention discloses a warehouse management system, which comprises a warehouse management server, a voice converter, an operation module, a database module and a wireless handheld terminal, wherein the wireless handheld terminal is connected with the database module via the operation module; the wireless handheld terminal is matched with a voice control module; the voice converter is controlled by the voice control module; the voice converter is arranged on the wireless handheld terminal; and the database module and the operation module are controlled by the warehouse management server. The warehouse management system has the beneficial effects that the above mode is adopted for managing the warehouse, conversation with the wireless handheld terminal can be carried out via a mobile voice communication device, as the wireless handheld terminal is kept by a warehouse keeper, a working person in charge of goods taking or goods storing can adopt a mobile phone for control according to an instruction of the warehouse keeper, a specific goods taking position or a specific goods storing position can be found out conveniently, and the working efficiency is greatly improved.

Owner:TAICANG CHENGZE NETWORK TECH CO LTD

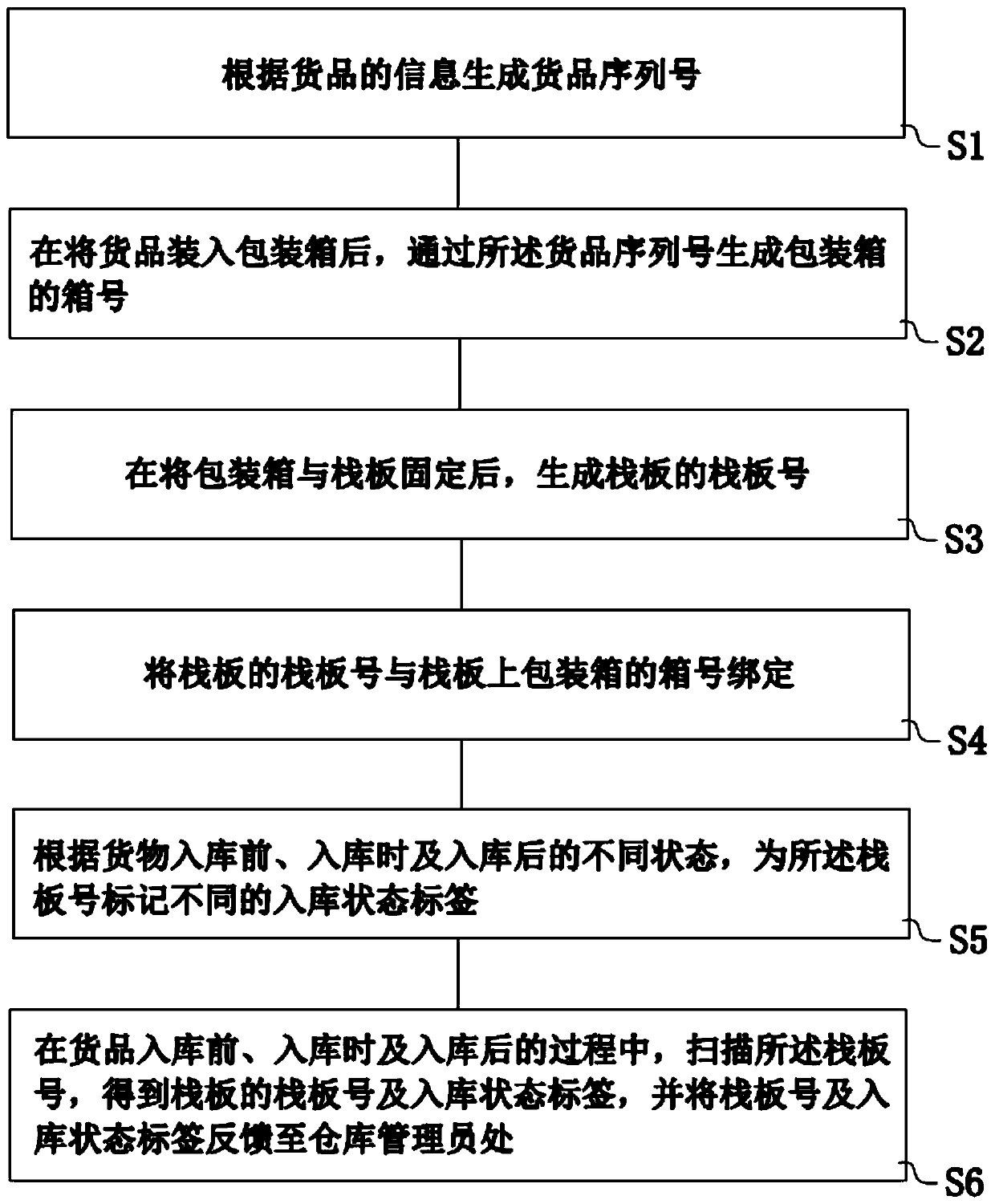

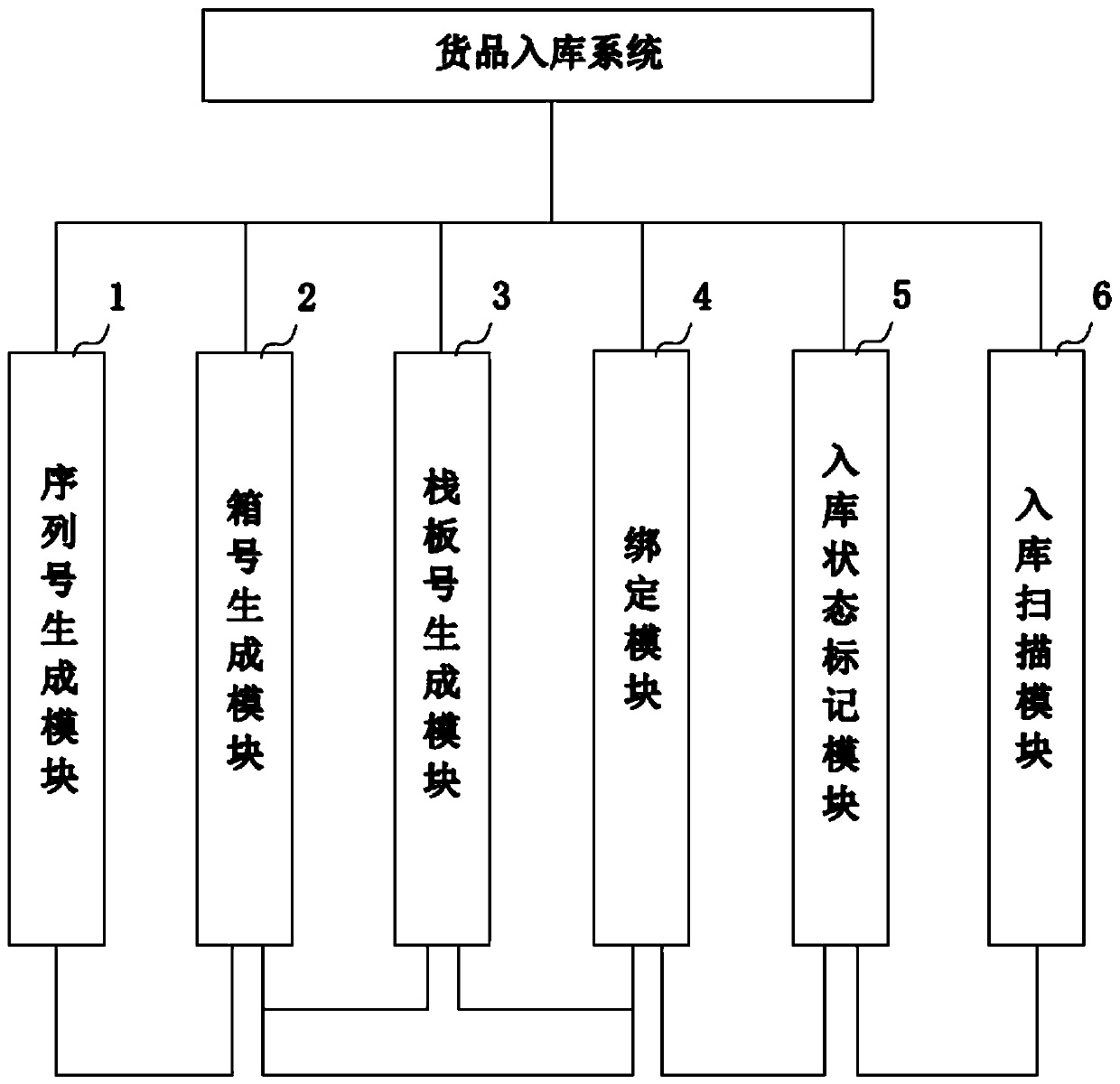

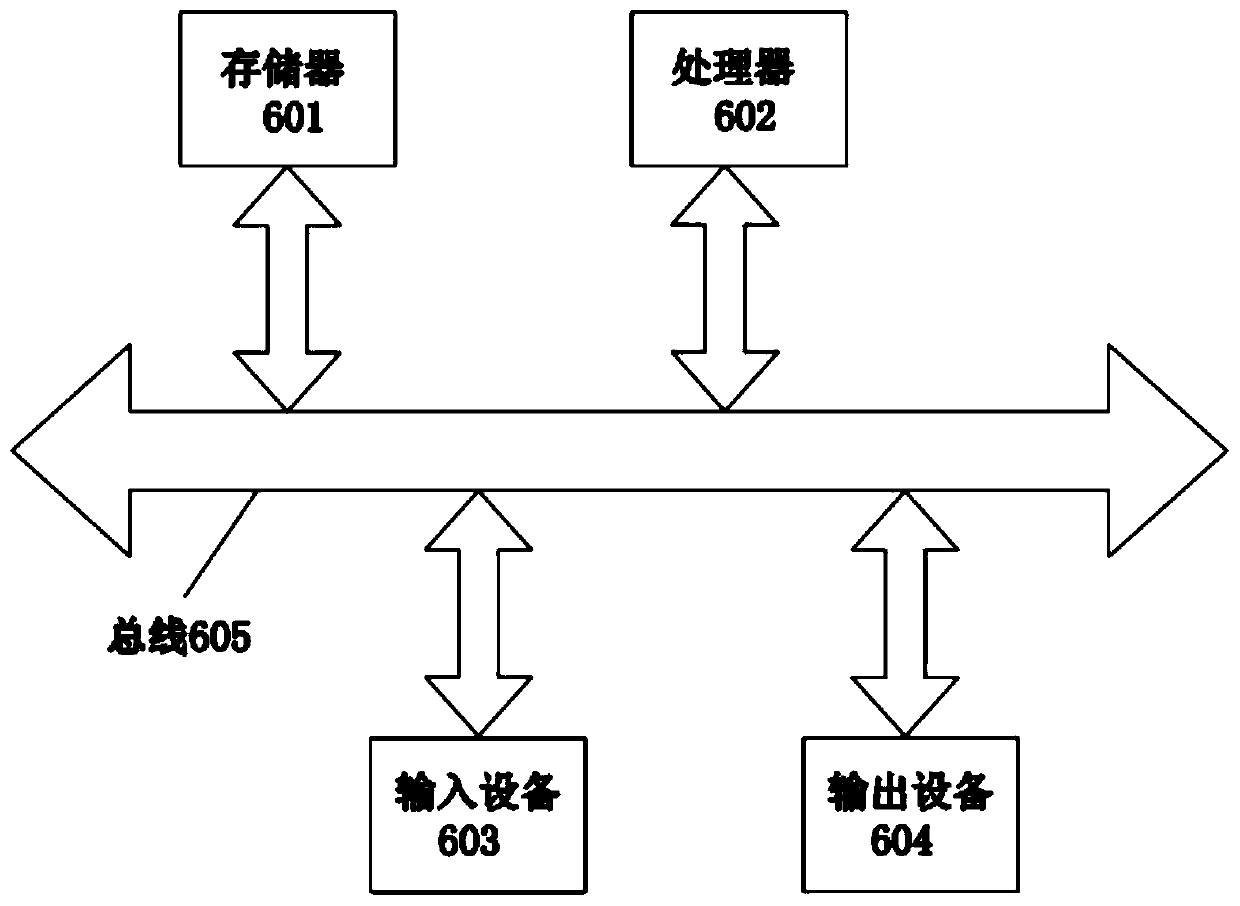

Goods warehousing method and system, electronic device and storage medium

InactiveCN110264131ARealize all-round monitoringReduce the difficulty of deploymentLogisticsWarehousemanSerial code

The invention discloses a goods warehousing method and system, an electronic device and a storage medium, and relates to the technical field of warehouse management and control. The method and the system are used for warehouse management and control, and solve the problem that difficulty is increased for later allocation of cargoes due to the fact that the number of cargoes recorded in a case is inconsistent with the number of actual cargoes in the prior art. The method comprises: generating a box number of the packaging box through the goods serial number; after the packaging box and the pallet are fixed, generating the pallet number of the pallet; binding the pallet number of the pallet with the box number of the packaging box on the pallet; marking different warehouse-in state tags for the pallet numbers; scanning pallet numbers before, during and after goods are warehoused to obtain pallet numbers and warehousing state tags of pallets, and feeding the pallet numbers and the warehousing state tags back to a warehouse manager. Therefore, the probability that the number of cargos recorded in the case is inconsistent with the actual number of cargos is reduced, and the allocation difficulty of the cargos in the later period is reduced.

Owner:SHENZHEN GIEC DIGITAL CO LTD

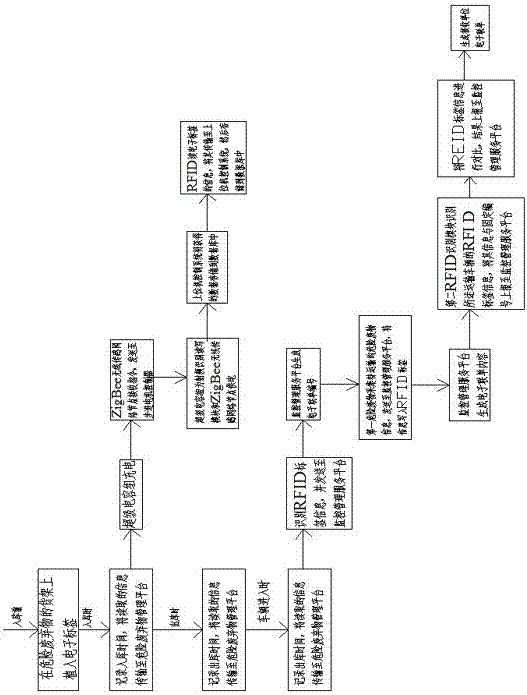

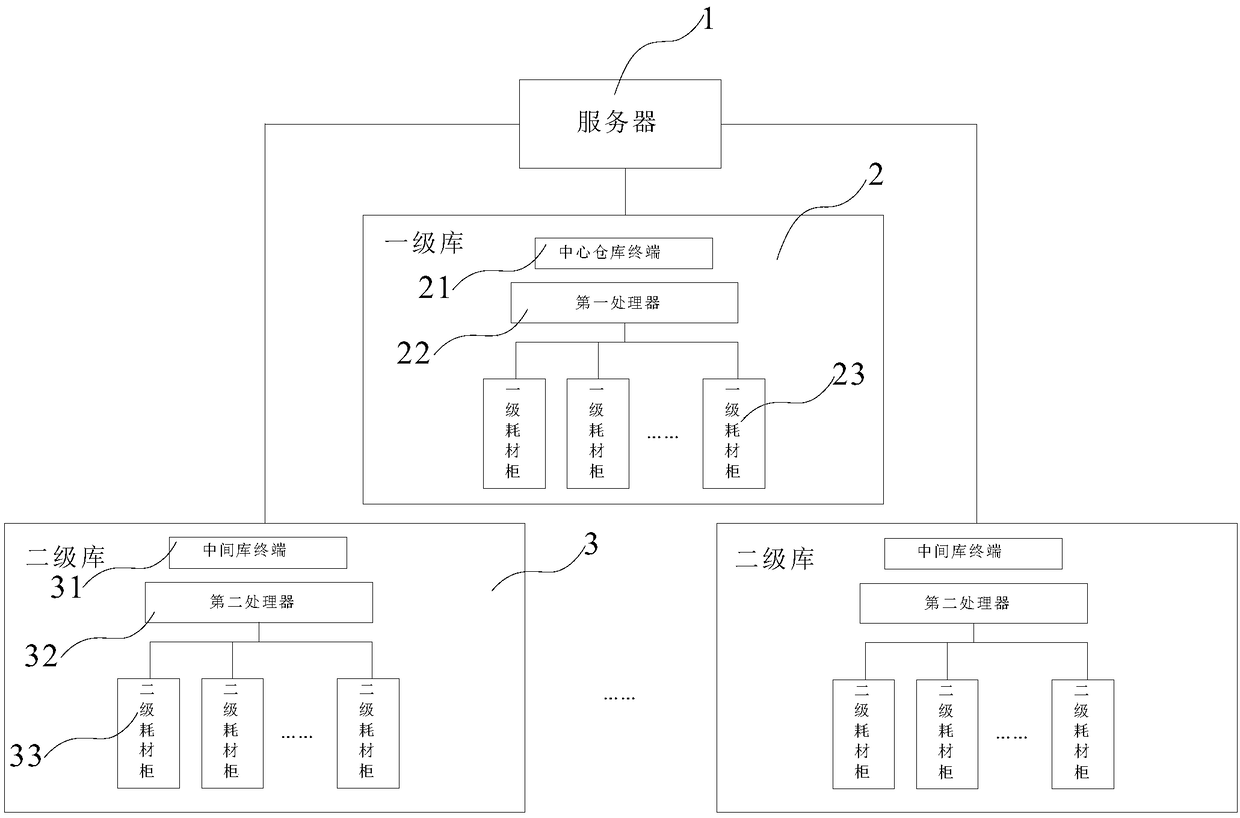

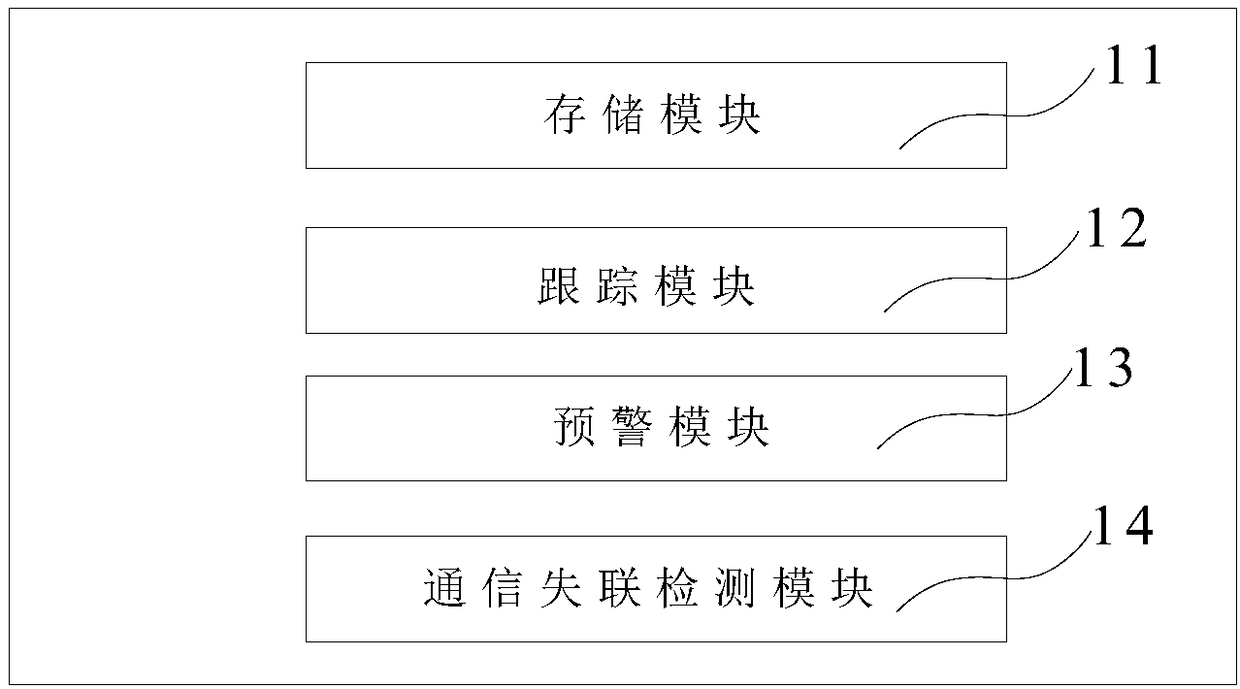

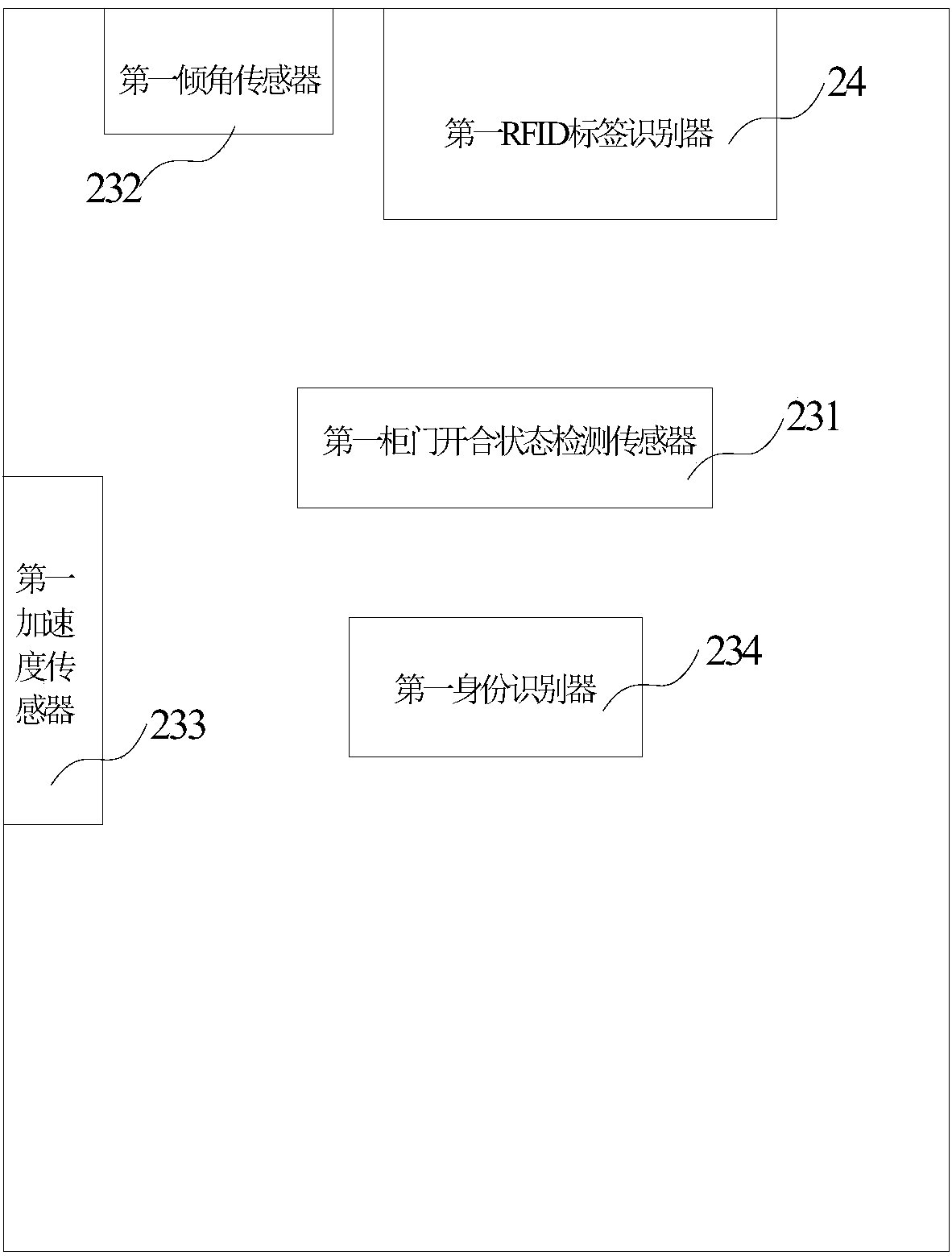

Intelligent consumable early warning system based on RFID technology

PendingCN108376277AAvoid risk of lossAvoid damageCo-operative working arrangementsWarehousemanComputer architecture

The invention discloses an intelligent consumable early warning system based on an RFID technology. The intelligent consumable early warning system based on the RFID technology comprises a server, a primary library and at least one secondary library; the primary library comprises a central warehouse terminal, a first processor and a plurality of primary consumable cabinets, a first RFID tag identifier is arranged in the each primary consumable cabinet, the each first RFID tag identifier is connected with the first processor, the central warehouse terminal and the first processor are respectively in communication connection with the server; the secondary library comprises an intermediate library terminal, a second processor and a plurality of secondary consumable cabinets, a second RFID tagidentifier is arranged in each consumable cabinet, the each second RFID tag identifier is connected with the second processor, and the intermediate library terminal and the second processor are in communication connection with the server; and the server is provided with a storage module, a tracing module and an early warning module. By adopting the intelligent consumable early warning system, theused consumables can be initiatively traced, and the warehouse manager or a user can be reminded of treating the consumables which are stored, used or scraped in time.

Owner:江苏人先智能医疗有限公司

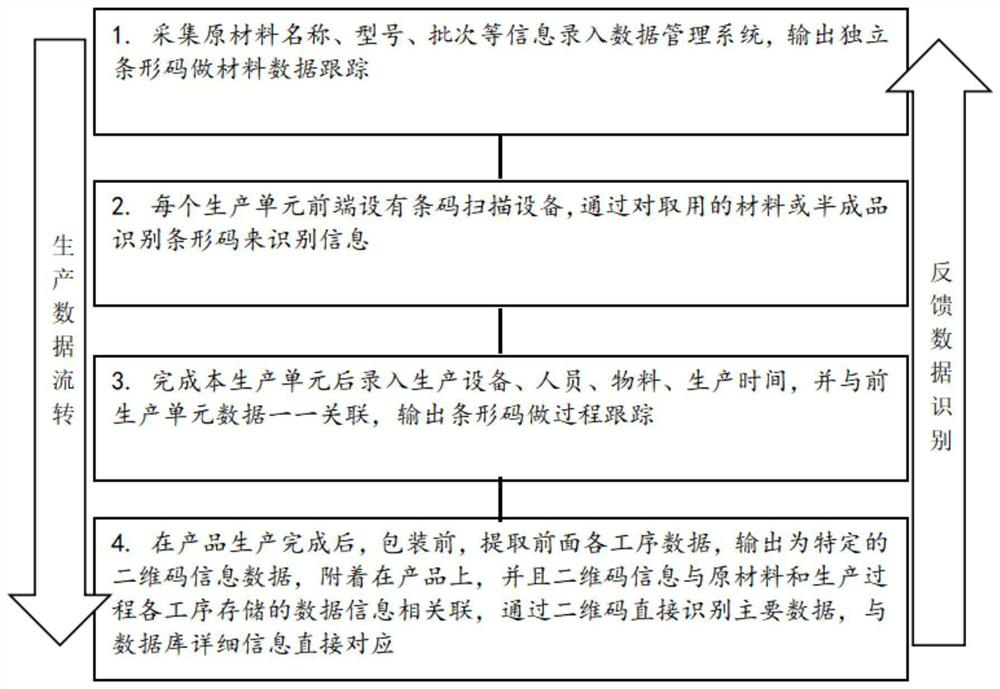

Rubber tube information tracing method based on two-dimensional code recognition technology

InactiveCN113298531AShorten the timeIncrease speedCo-operative working arrangementsCommerceData informationBarcode

The invention relates to the technical field of automobile part production management, in particular to a rubber tube information tracing method based on a two-dimensional code recognition technology, which comprises the following specific steps: S1, preparing raw materials, warehousing the raw materials after the raw materials are qualified through inspection, inputting information such as material names, models, batches, quantity and suppliers into a data management system by a warehouse manager, outputting the independent bar code, forming the independent bar code, and attaching the independent bar code to the identification recognition area of the corresponding raw material storage position; s2, installing bar code scanning equipment at the front end of each production unit; and S3, when the raw materials are delivered out of the warehouse, enabling workers to take various needed materials from the warehouse. Compared with traditional independent batch number information, the scheme can provide more materials and key data in the product production process only through the two-dimensional code, the information is complete and accurate, meanwhile, the query speed is high, the time for repeatedly querying historical data and recording a form is shortened, and the rapidness is improved.

Owner:北京天元希米尔汽车零部件有限公司

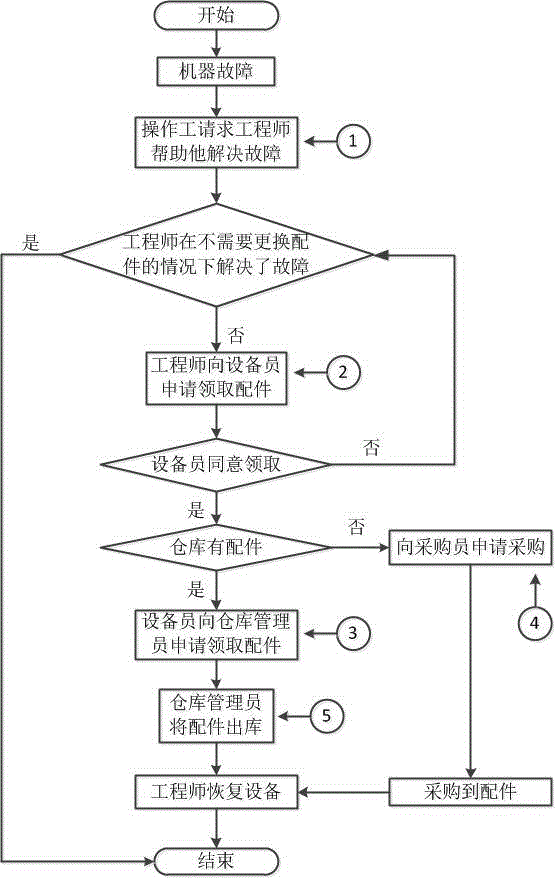

Set of management software for manufacturing enterprise to get spare and accessory parts

InactiveCN106203759AReduce the situation of not receiving accessoriesResourcesLogisticsStatistical analysisSoftware engineering

The invention discloses a set of management software for a manufacturing enterprise to get spare and accessory parts, and can enhance the efficiency of a maintenance engineer for fault processing. The management software comprises a client side and a server side. The flow of getting the accessory parts is shown in the drawings. The time-consuming process of getting the accessory parts is solved. An administrator logs in the system from the server side and distributes the authority to a user. An operator, the maintenance engineer and a warehouse keeper log in through a mobile terminal to perform relevant operation. The links (1,2,3,4 and 5) do not require personal attending to the specific position and the objective is achieved by software operation. The server side forwards response data to the client side according to a request transmitted by the user. System background software monthly performs statistical analysis on the data of getting the accessory parts of the factory so as to formulate a corresponding accessory part purchasing plan. Meanwhile, the management software also has the function of lower limit alarm for the residual number of the accessory parts so that the situation that the accessory parts cannot be got can be reduced.

Owner:何正方

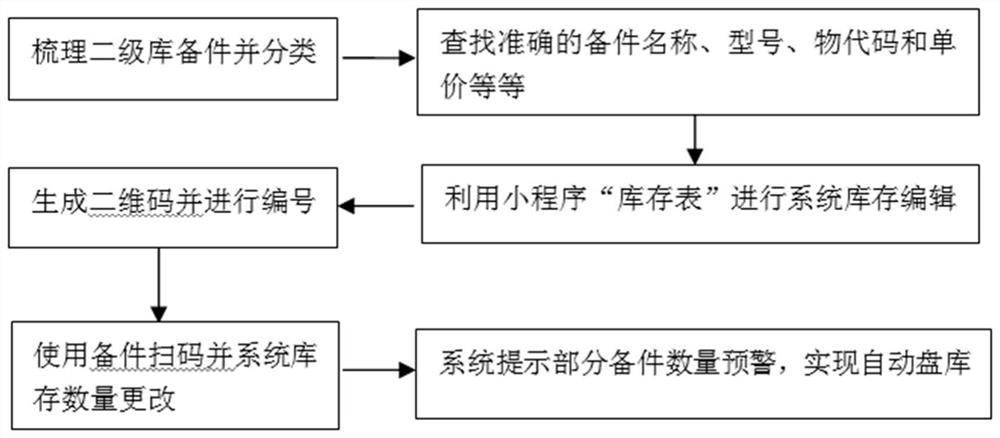

Inventory management method based on two-dimensional code

PendingCN112288370AConvenient queryEasy to storeDatabase updatingRelational databasesInventory managementWarehouseman

The invention relates to an inventory management method based on a two-dimensional code, and belongs to the technical field of computer spare part statistics. The inventory is classified; identification definition is performed on the classified inventory articles, wherein the definition comprises names, models, article codes and unit prices; the user terminal uploads the identified inventory itemsto the terminal; the terminal generates an independent two-dimensional code for the inventory article; the user side uses spare part code scanning to take and use the system inventory, and the quantity is changed; and the terminal performs early warning for the change of the inventory articles to realize automatic inventory checking. According to the inventory management method based on the two-dimensional code, warehouse entering and exiting personnel can conveniently inquire, enter and exit inventory through mobile phone code scanning, equipment administrators and warehouse administrators are successfully established for remote butt joint, the daily warehouse entering and exiting conditions and the total amount of secondary inventory of a warehouse can be known without going out, management of a workshop secondary inventory is facilitated, and the workload of warehouse management is greatly reduced.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

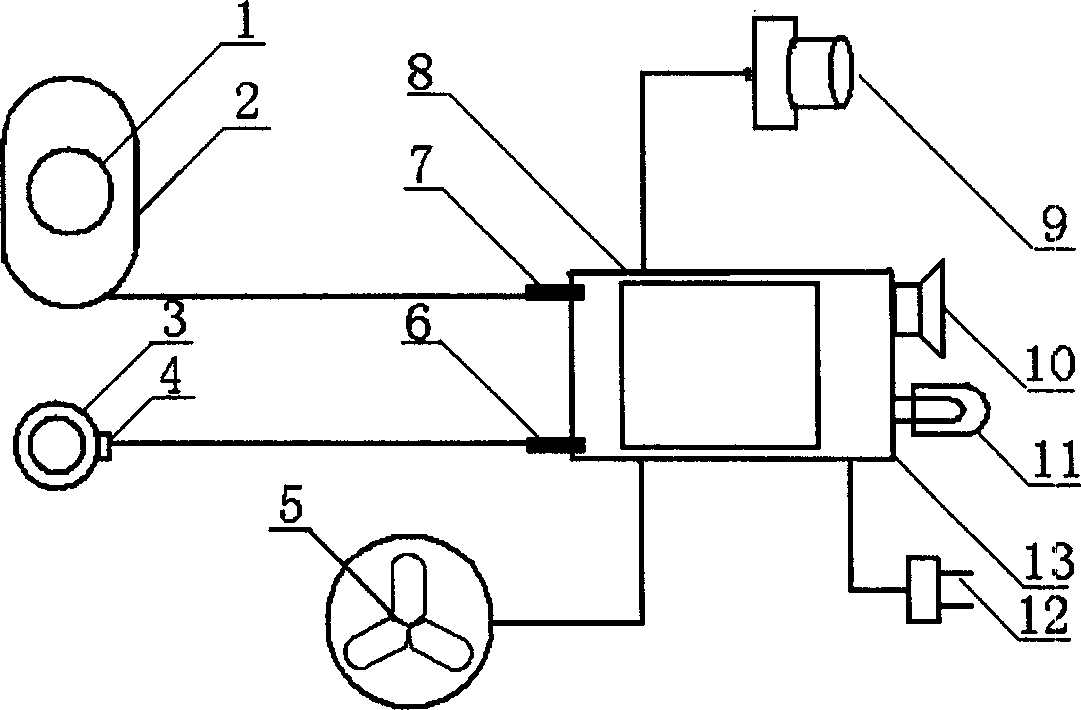

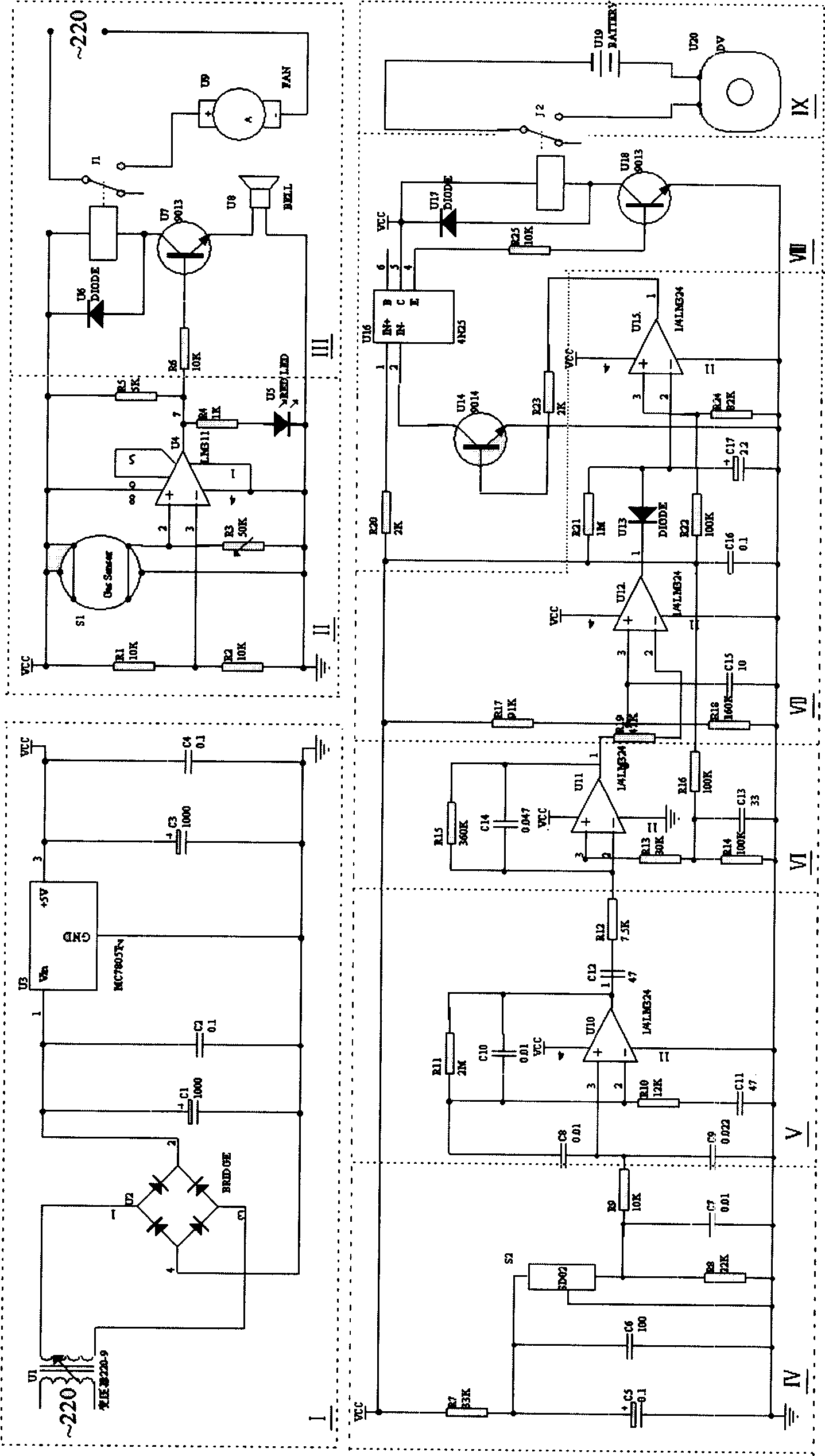

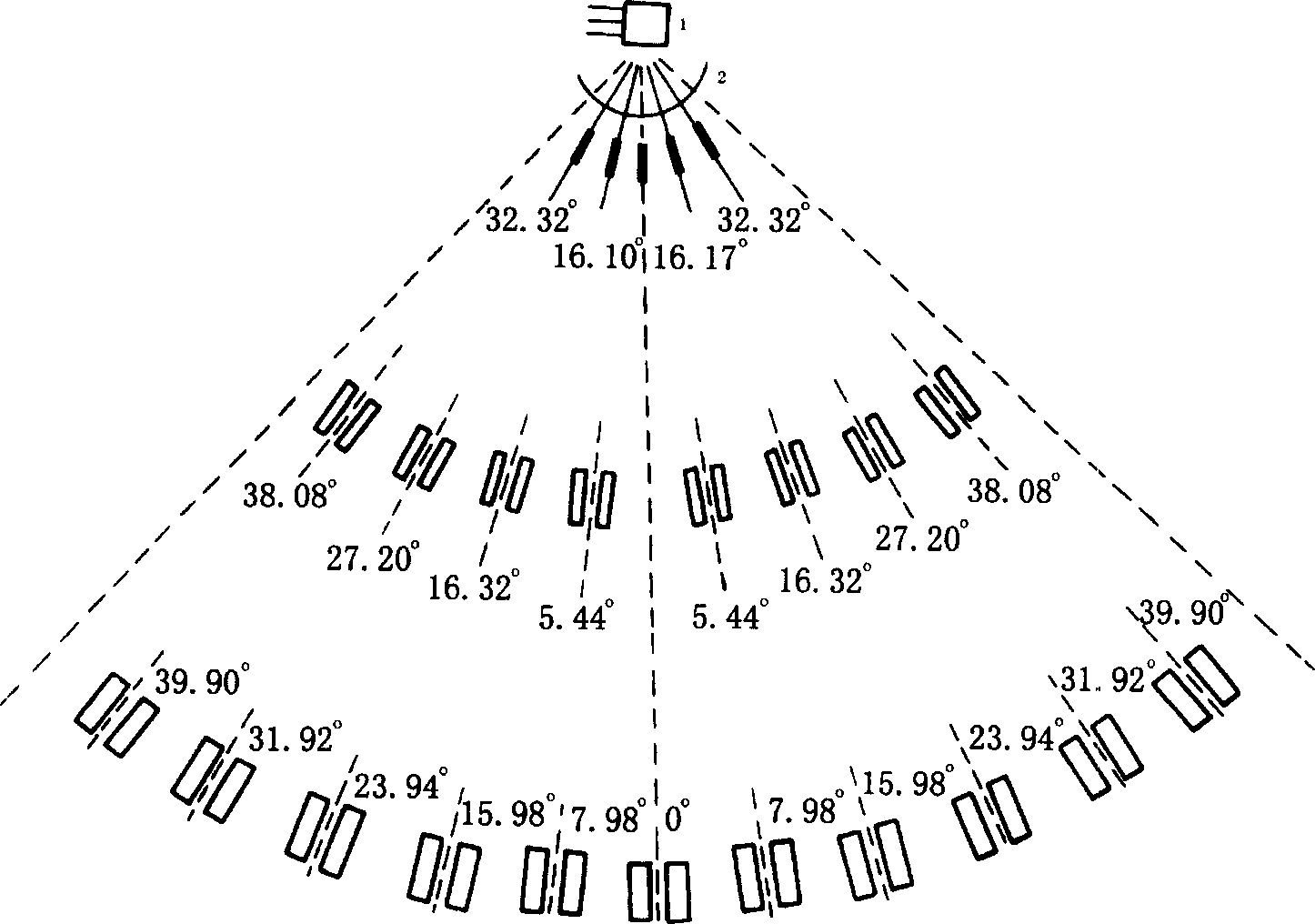

Anaesthetic therft preventing device and method

InactiveCN1529292AProtect life and property safetyFlexible expansionBurglar alarmFresnel lensElectricity

The device comprises infrared pyroelectric sensor, fresnel lens, minitype DV (or telephone), exhaust fan, sensor of narcotic poison gas, detection and control circuit. Alarming device composed of infrared pyroelectric sensor and sensor of narcotic poison gas through wire connected to the detection and control circuit is an effective device for keeping watch theft entering to room by using narcotic poison gas. Sensors of narcotic poison gas are distributed multiple places inside room. When gas occurs, exhaust fan starts up to remove gas, meanwhile audible and visual alarm reminds host or warehouseman. If criminal thrusts oneself into room, the minitype DV starts up to record happening things and dials alarming phone. The infrared pyroelectric sensor and sensor of narcotic poison gas are plug and play device for detection and control circuit, and the sensors are possible to extend to be used in wireless transmission module for signal connection.

Owner:HEFEI INST OF INTELLIGENT MACHINERY CHINESE ACAD OF SCI

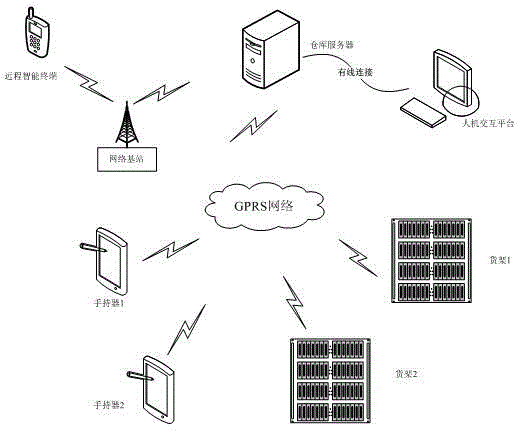

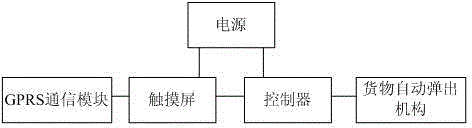

Intelligent warehouse management system and management method

InactiveCN104809609BSave yourself the trouble of findingShorten the timeLogisticsIntelligent managementHuman–robot interaction

The present invention discloses an intelligent warehouse management system and management method, including a remote intelligent terminal, a warehouse server, a human-computer interaction platform connected to the warehouse server, a plurality of shelves and hand-held devices, and the remote intelligent terminal and the warehouse server adopt Data interaction is realized by wireless communication, the human-computer interaction platform is connected to the warehouse server by wire, and the remote intelligent terminal, handsets and shelves are connected to the warehouse server by wireless communication to query cargo information. The invention discloses an intelligent warehouse management system, which realizes the data transmission between the customer and the warehouse through wireless communication, and at the same time realizes the intelligent management in the warehouse, and automatically recognizes the position of the goods, eliminating the need for the warehouse administrator to check the goods tediously Work.

Owner:NANTONG VOCATIONAL COLLEGE

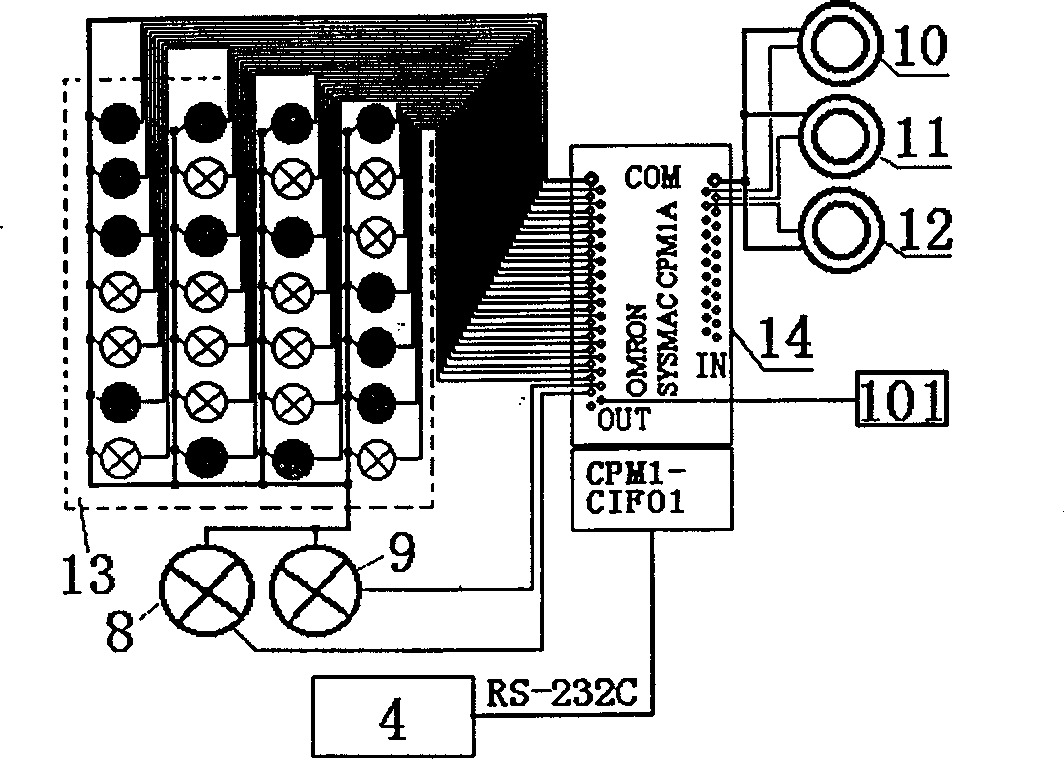

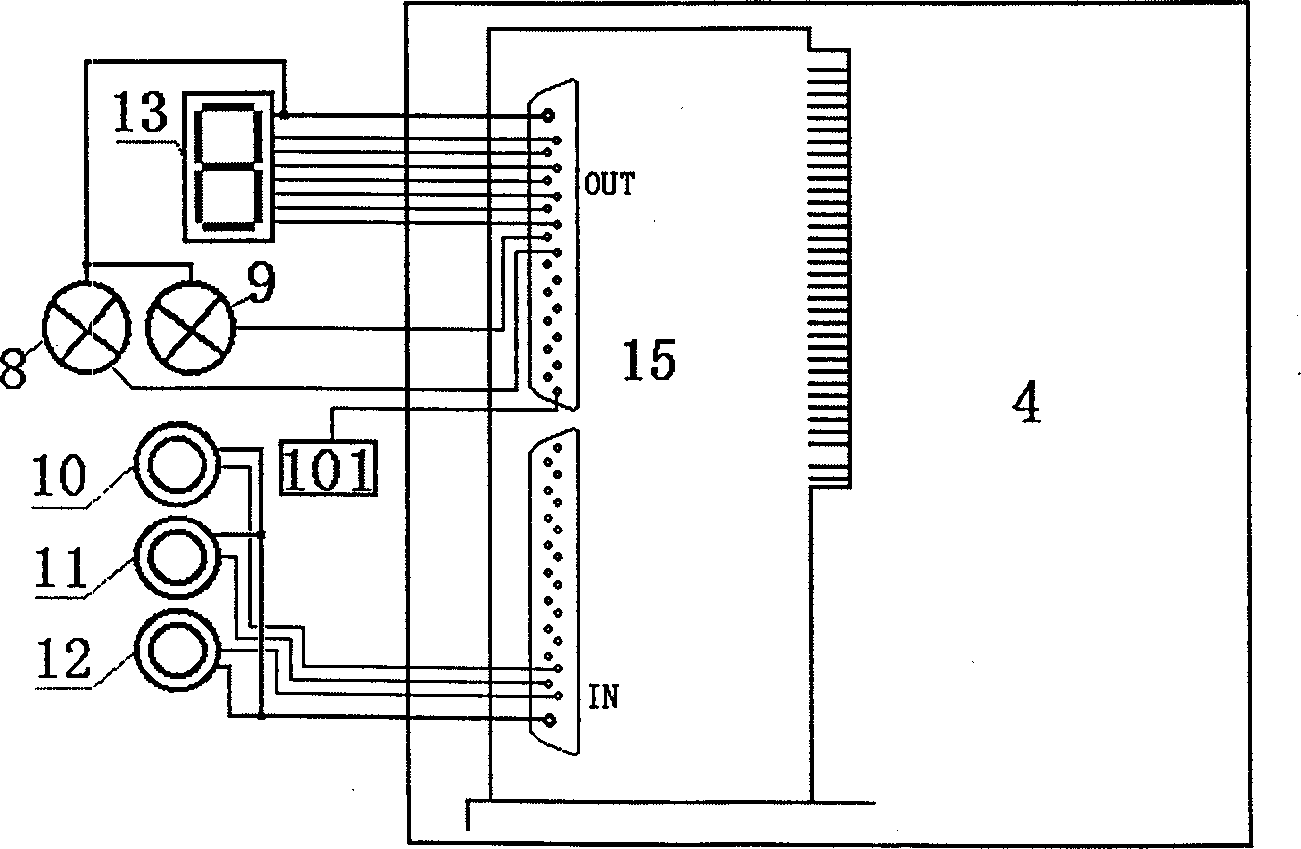

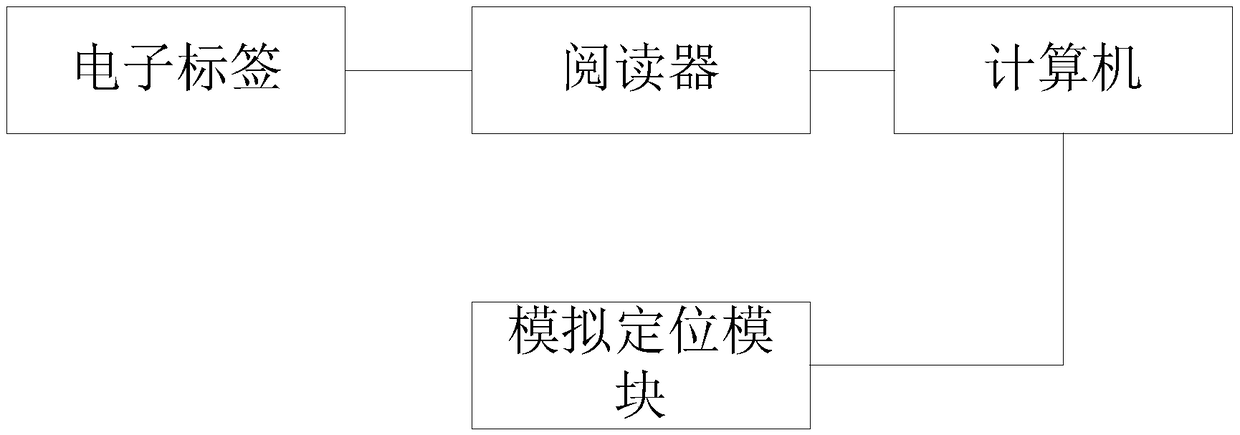

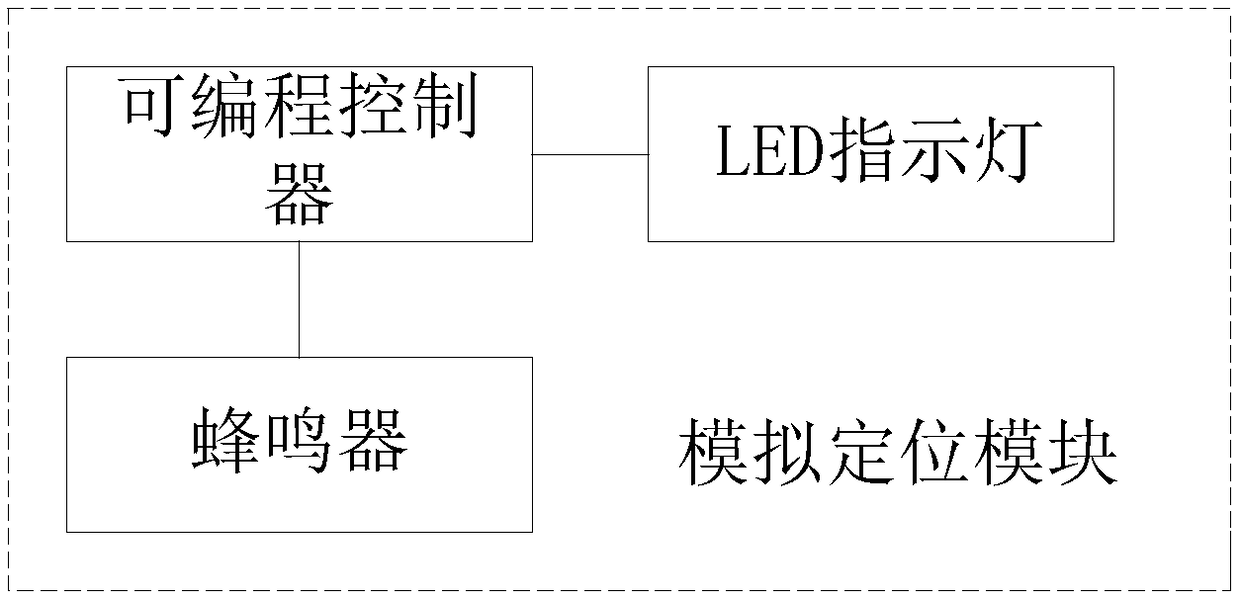

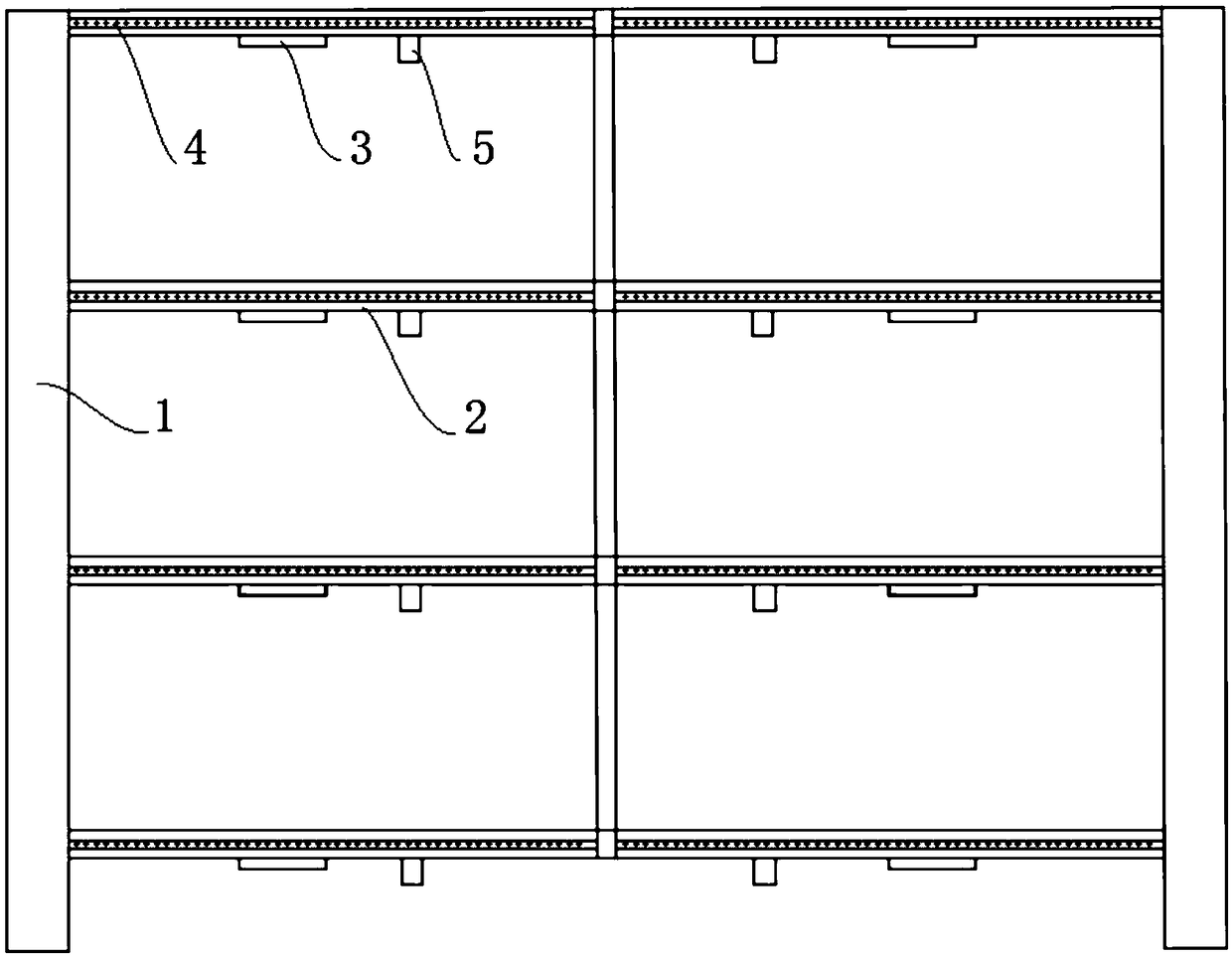

Warehouse management system based on indoor location

InactiveCN109118142AHave an inventoryConvenient statisticsCo-operative working arrangementsLogisticsCommunication interfaceWarehouseman

The invention discloses a warehouse management system based on indoor positioning, including storage shelves, the warehouse shelf is provided with a partition board arranged in a multi-layer partition, an electronic tag for storing goods information is detachable on the bottom surface of the partition plate, and a reader for reading the electronic tag information, a read is wirelessly connected tothat electronic tag through an antenna, the reader is connected with the computer through the RS232 communication interface, and a simulation positioning module is also arranged on the storage shelf,and the simulation positioning module is connected with the computer through the communication interface, and the simulation positioning module comprises a programmable controller, and an output endof the programmable controller is connected with an indicating device. The simulation positioning module is provided with a buzzer and an LED indicator to guide the warehouse administrator to search for the target goods, quickly complete the picking operation, and thoroughly solve the problem of difficult goods searching. The simulation positioning module is provided with a buzzer and an LED indicator.

Owner:CHENGDU FLAME TECH

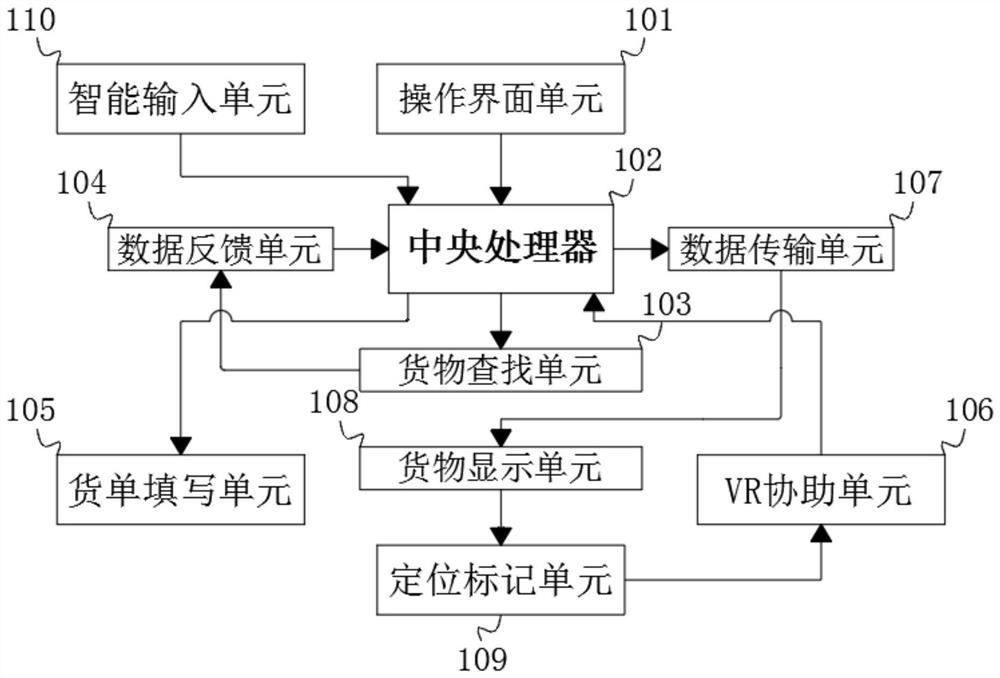

Warehouse management software management technology and software management system

PendingCN111754169AEasy to manageReduce the burden onLogisticsExecution for user interfacesData transportWarehouseman

The invention discloses a warehouse management software management technology and a software management system, and relates to the technical field of warehouse management. The technology comprises steps of S1, firstly, interface operation of warehouse management software is carried out through an operation interface unit, and then goods are searched for through a goods searching unit after analysis and processing are carried out through a central processing unit. Based on the warehouse management software management technology and the software management system, goods information is extractedthrough the goods information module; the information passes through an analysis module, an information input module, a receipt generation module, a printing module and a classified storage module; automatically generating shipment bills; printing and classified storage are conducted at the same time, manual filling is not needed, goods receipts are easy to manage, meanwhile, the VR assistance unit, the data transmission unit, the goods display unit and the positioning marking unit are matched, goods in the warehouse can be checked in a fixed-point mode in real time, patrol inspection of operators is not needed, and the burden of a warehouse manager is greatly relieved.

Owner:无锡艇客信息科技有限公司

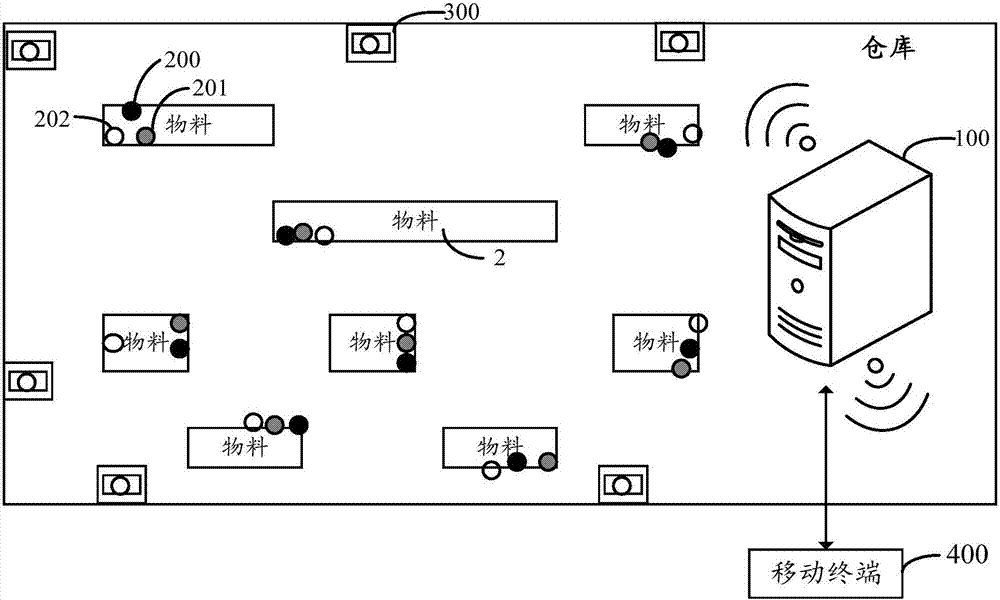

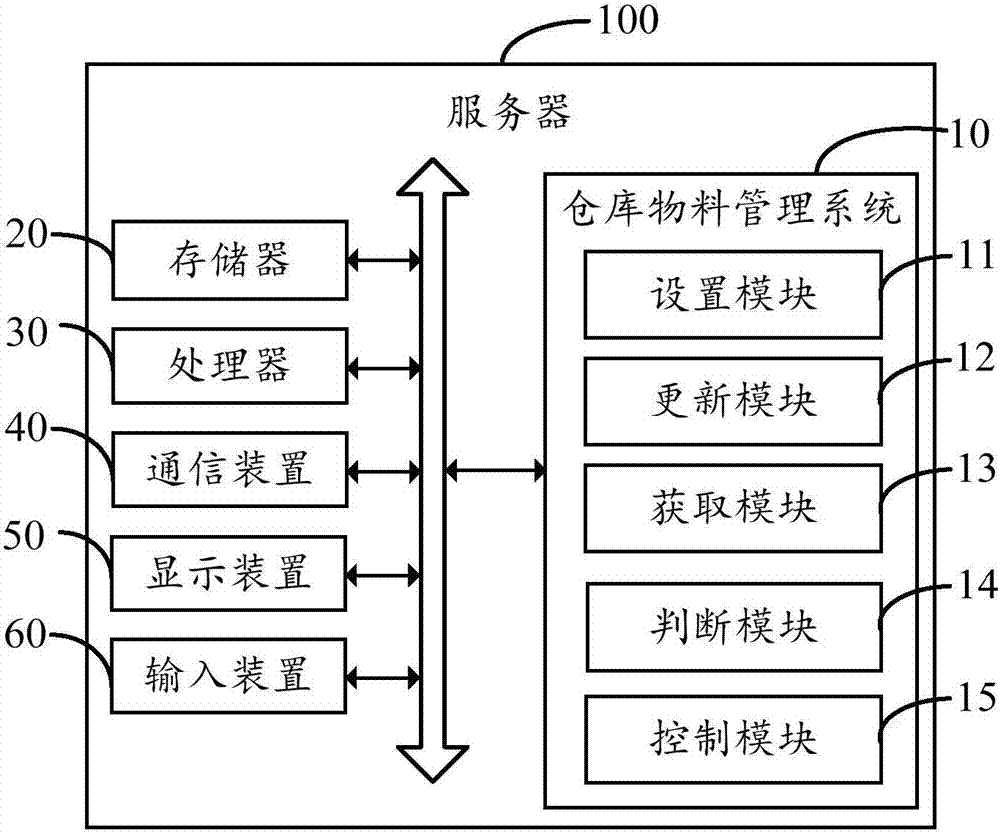

Warehouse material management system and method

InactiveCN107292548AEasy to manageConvenient management inventoryLogisticsBurglar alarmComputer moduleWarehouseman

The invention relates to a warehouse material management system and method applied to a server. The system comprises a setting module, an acquiring module, a determination module, and a control module. To be specific, the setting module is used for providing a setting interface for a warehouse administrator to set basic information of a unit material when each unit material is put into the warehouse and associating the basic information with a corresponding positioning tag. The acquiring module is used for obtain position information localized by each positioning tag as well as state information of the unit material corresponding to each positioning tag at each preset interval unit material. The determination module is used for determining whether any unit material exceeds a boundary area of the warehouse and determining whether the unit material is in a warehouse-out allowing state based on the state information corresponding to unit material if the unit material exceeds the boundary area of the warehouse. And the control module is used for sending a control instruction to control the positioning tag corresponding to the unit material to send out alarming sound when the unit material beyond the boundary area of the warehouse is not in a warehouse-out allowing state.

Owner:FU TAI HUA IND SHENZHEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com