Preparation method of high-power lithium ion battery positive electrode and lithium battery

A cathode material, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low electron conductivity, instability, low lithium ion diffusion coefficient, etc., and achieve both conductivity and coating effect improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

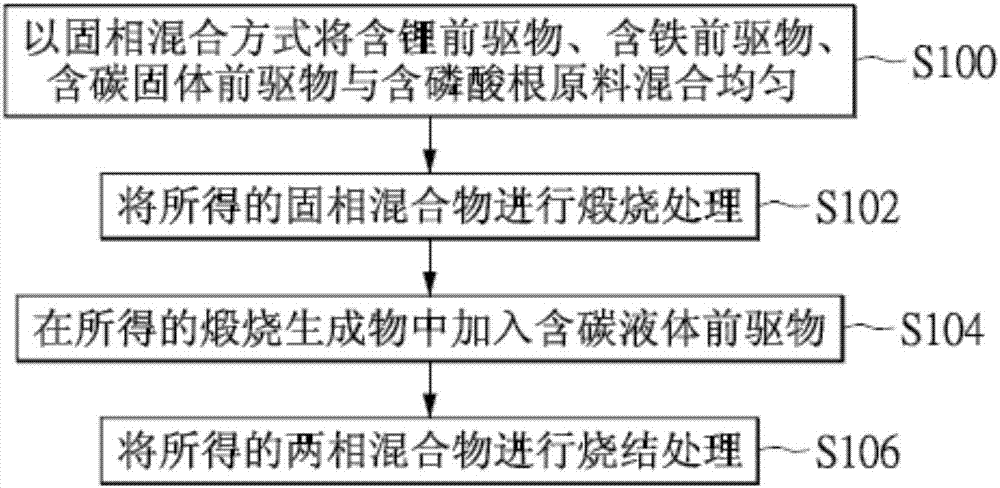

[0028] Please refer to figure 1 , the first embodiment of the present invention provides a method for preparing a high-power lithium battery positive electrode material, which mainly prepares lithium iron phosphate / carbon material by a reduction-solution method; figure 1 As shown, the preparation method includes: step S100, uniformly mixing lithium-containing precursors, iron-containing precursors, carbon-containing solid precursors and phosphate-containing raw materials in a solid phase mixing manner; step S102, performing the solid phase mixture obtained Calcination treatment; step S104, adding a carbon-containing liquid precursor to the obtained calcined product; and step S106, performing sintering treatment on the obtained two-phase mixture.

[0029] When step S100 is actually implemented, solid reactants such as lithium-containing precursors, iron-containing precursors, and carbon-containing solid precursors can be placed in a high-speed mixer and mixed evenly, and then t...

no. 2 example

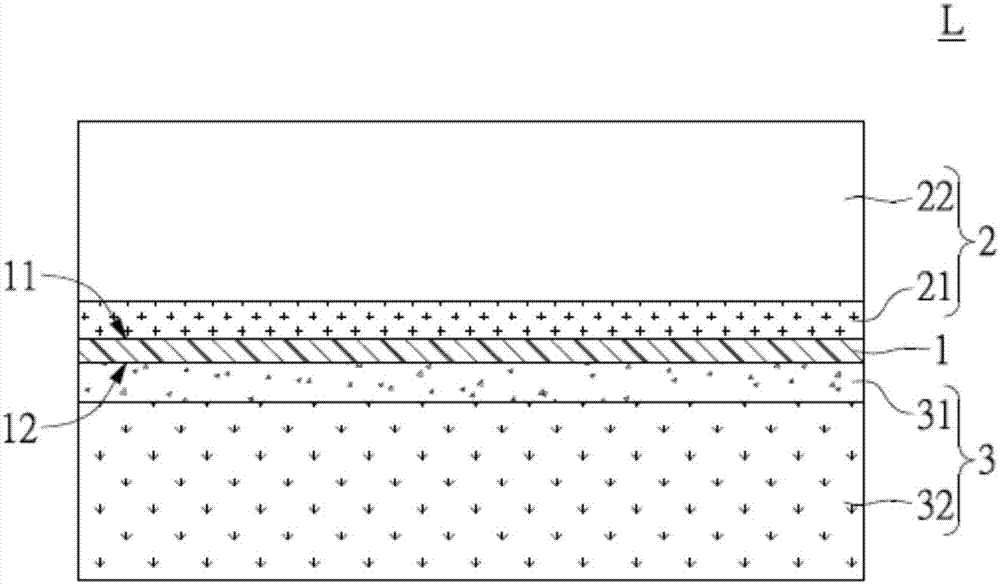

[0045] Please refer to image 3 , The second embodiment of the present invention further provides a lithium battery L, which mainly includes an isolation layer 1 , a positive electrode structure 2 and a negative electrode structure 3 . From a structural point of view, the isolation layer 1 has a first surface 11 and a second surface 12 opposite to the first surface 11, the positive electrode structure 2 is disposed on the first surface 11 of the isolation layer 1, and the positive electrode structure 2 includes an anode layer 21 and A positive electrode collector layer 22, wherein one side of the positive electrode layer 21 is connected to the first surface 11, the other side of the positive electrode layer 21 is connected to the positive electrode collector layer 22, and the negative electrode structure 3 is arranged on the second surface of the isolation layer 1 12 , the negative electrode structure 3 includes a negative electrode layer 31 and a negative electrode collector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com