Variable antisticking roller for sowing

A compactor and anti-stick technology, applied in the application, planting method, excavation/covering of trenches, etc., can solve the problems of single adaptability of the compaction wheel, clay and other problems, achieve simple and convenient adjustment and operation, prevent soil sticking, structure novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

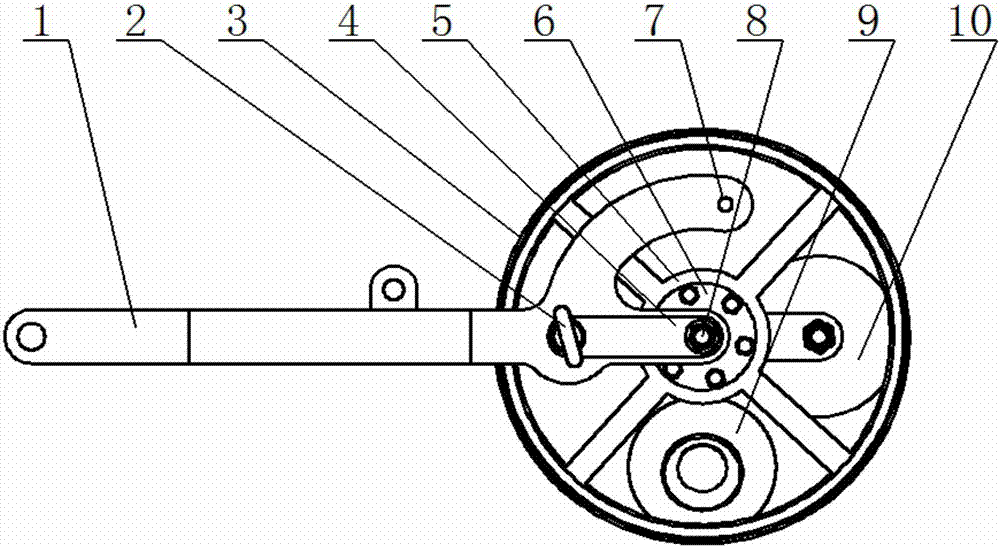

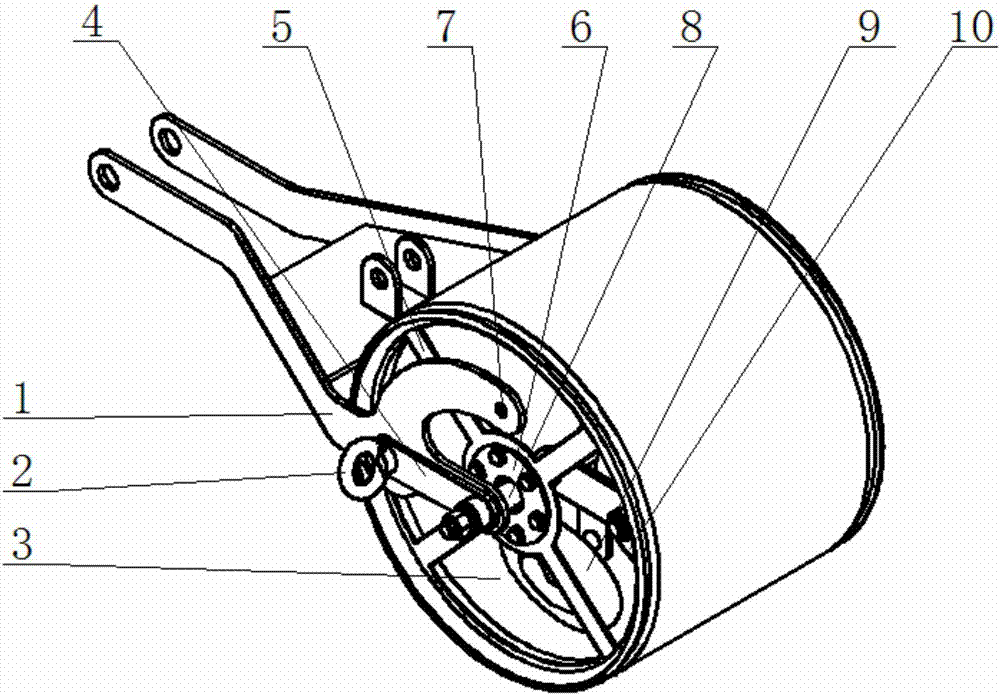

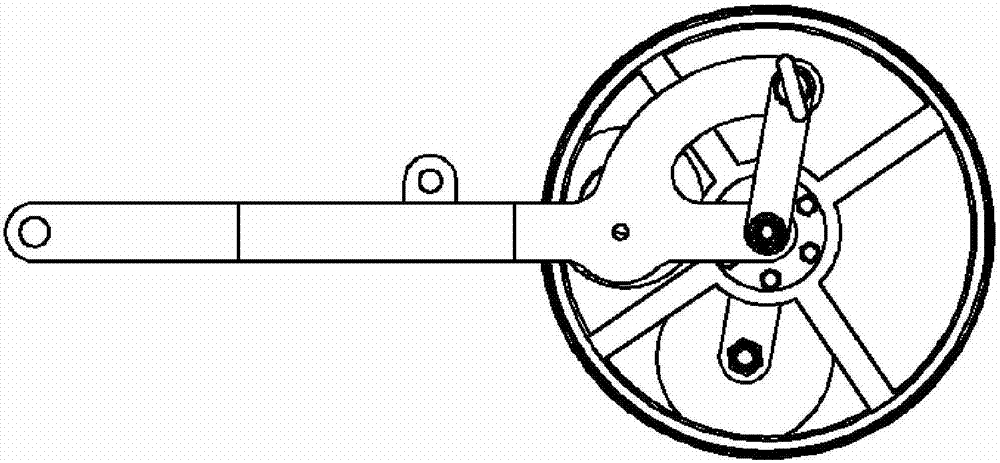

[0013] Below in conjunction with accompanying drawing, the embodiment that the present invention creates is described in detail:

[0014] A modified anti-stick suppressor for sowing. A suppressor wheel shaft 8 is installed at the end of the suppressor frame 1. The two ends of the suppressor wheel shaft 8 are installed on the inner side of the suppressor frame 1 with a suppressor wheel side plate 5. The interior of the suppressor wheel side plate 5 is supported by a bearing The end cover 6 is fixed with a bearing 11, and the bearing 11 is in rotation with the packer shaft 8; the outer edge of the side plate 5 of the packer wheel is fixed with a rubber sleeve 3; Wheel 10; the pressing wheel shaft 8 is fixed on the outer side of the pressing frame 1 and the V-shaped pressing wheel 9 at right angles to the adjusting arm 4, and the outer end of the adjusting arm 4 is installed with the positioning screw 2 through the positioning hole 7, and the positioning hole 7 Set on the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com