A Machine Tool Chatter Online Monitoring Method Based on Wavelet Packet and Hilbert Transform

A wavelet packet and flutter technology, which is used in measuring/indicating equipment, metal processing mechanical parts, special data processing applications, etc., can solve the problem of real-time flutter monitoring and online monitoring algorithms in processing signals for long-term processing path data. and other problems to achieve the effect of online identification and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

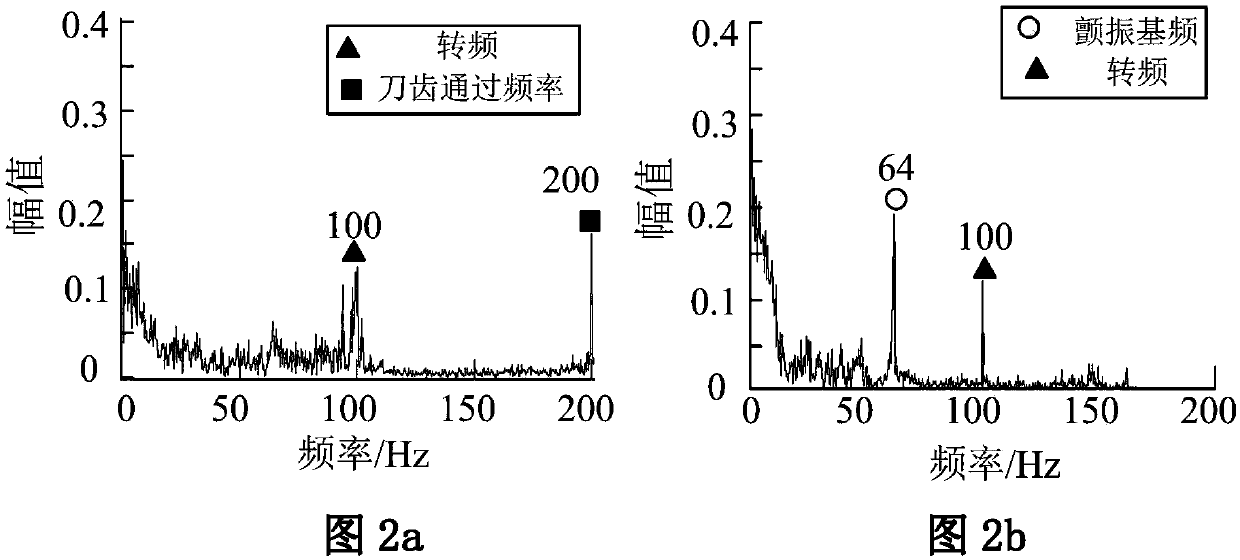

[0037] Because the fundamental frequency of flutter has good sensitivity to the system, as long as the stability of the system changes, it can appear in the frequency spectrum of the signal after wavelet packet and Hill transform. It overcomes the shortcomings of traditional monitoring methods that require long-term processing path data, and can realize early identification of chatter, which is of great significance for online monitoring of cutting chatter status.

[0038] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

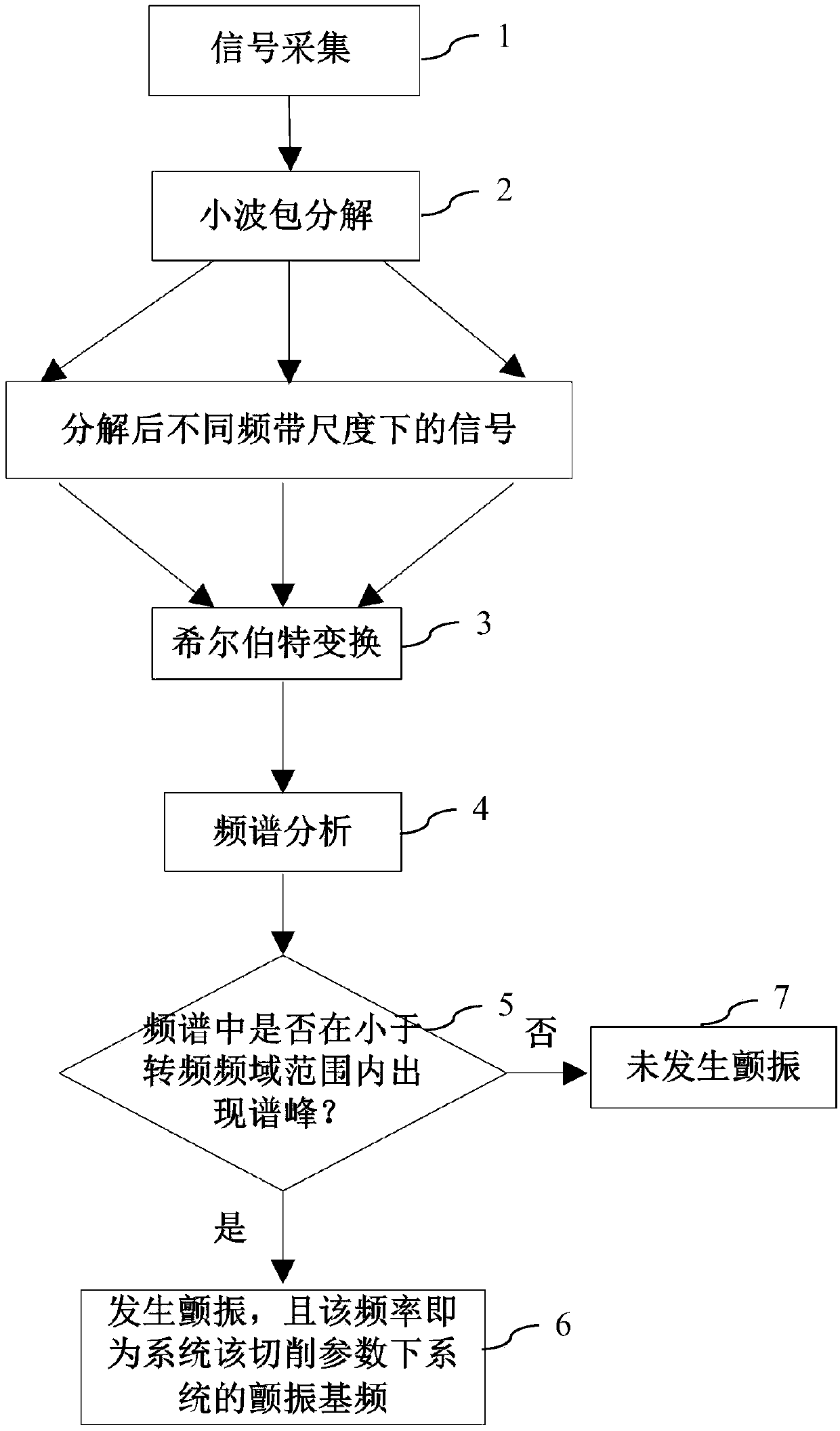

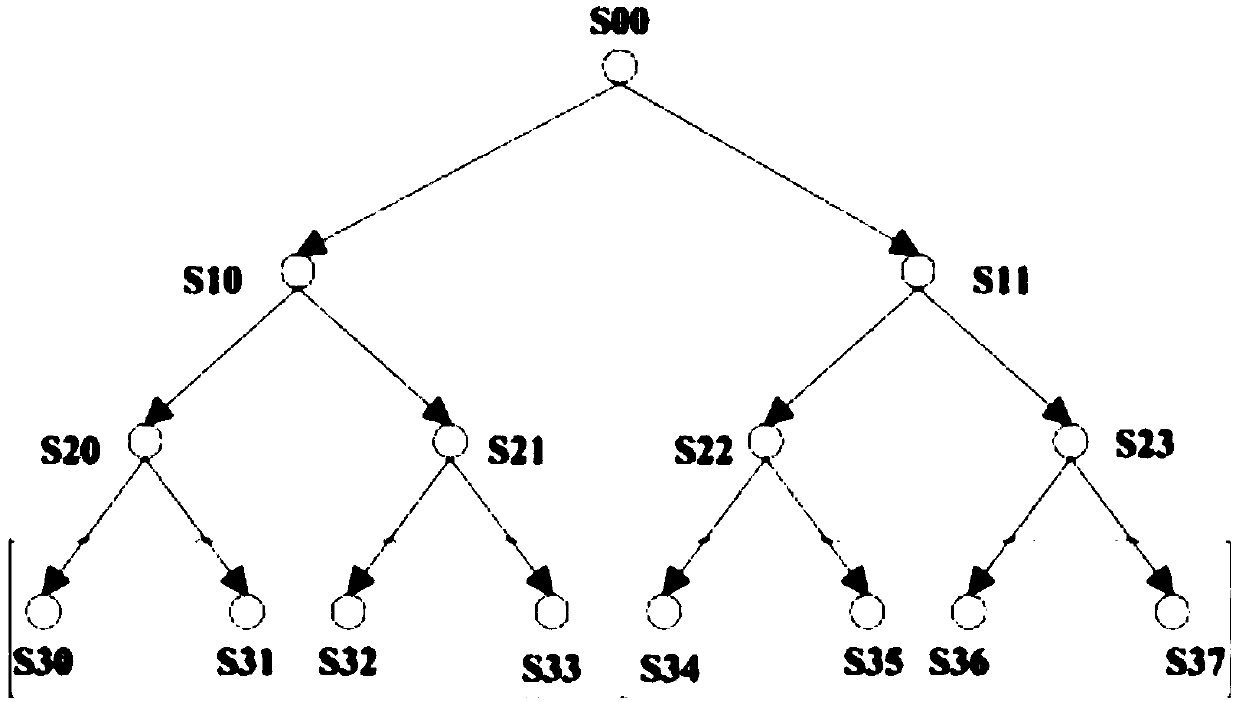

[0039] Such as figure 1 As shown, a kind of cutting chatter on-line monitoring method flow process based on wavelet packet and Hilbert transform of the present invention comprises the following steps:

[0040] Step 1. Obtain the original signal of the cutting process within a certain period of time. The original signal mainly includes the cutting force signal between the tool and the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com