Pulling belt type round log splicing machine and round log splicing method

A round machine and frame technology, applied in the field of pull belt round splicing machine and round splicing, can solve the problems of dislocation and deformation of hollow logs, and achieve the effect of convenient and quick removal, convenient and fast operation, and improved splicing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

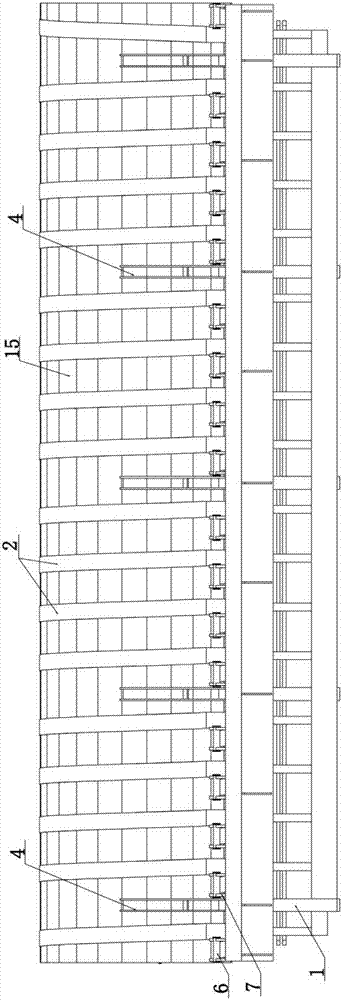

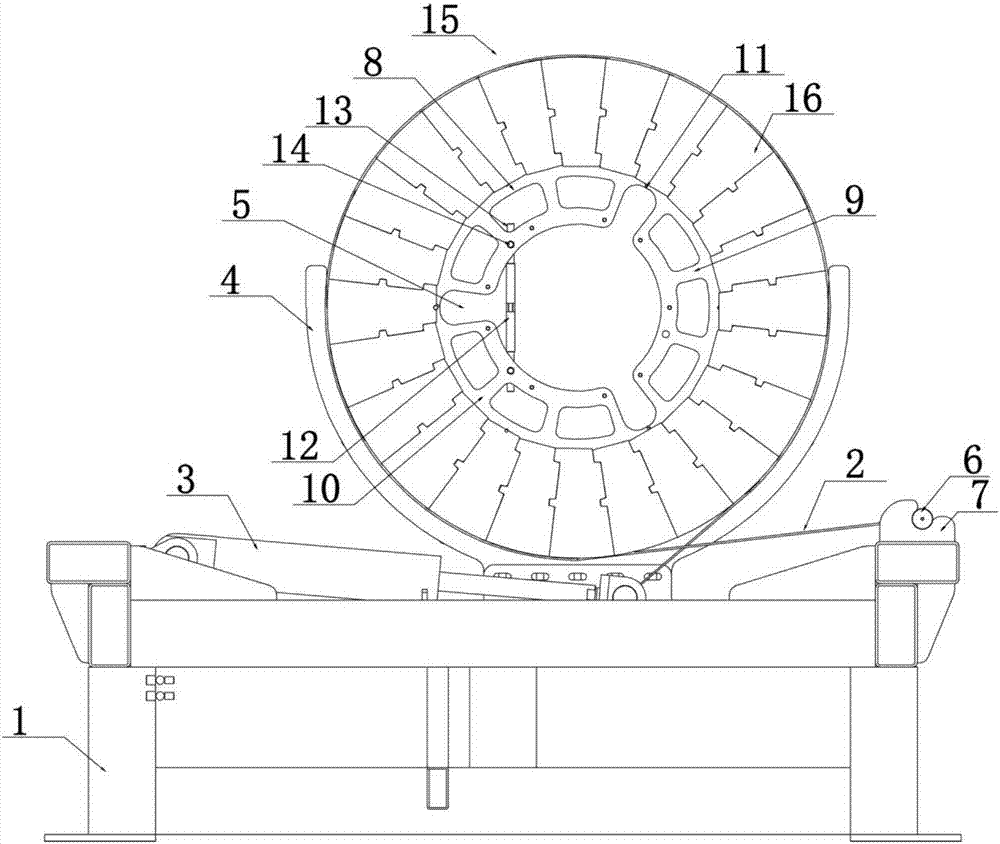

[0040] Example 1, such as Figure 1-Figure 3 As shown, a drawstring type round machine includes a frame 1, a plurality of drawstrings 2 evenly arranged on the frame and a tension cylinder 3, and also includes an outer support for supporting the outer wall of a hollow log frame 4 and the inner support frame 5 for supporting the inner wall of the hollow log, the inner support frame is provided with two, the inner support frame is arranged on the two ends of the hollow log, the outer wall of the inner support frame and the hollow log The inner wall of the hollow log is adapted, the outer support frame is installed on the frame, and the outer support frame is provided with at least two, and the outer support frame is evenly arranged along the length direction of the hollow log, and the outer support frame The radian of the inner wall of the hollow log is consistent with the radian of the outer circumference of the hollow log, the cylinder body of the tensioning cylinder is install...

Embodiment 2

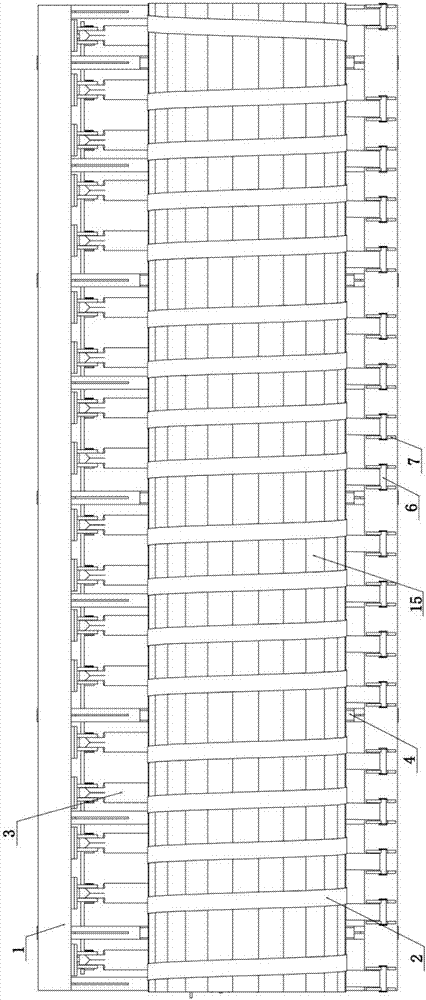

[0044] Example 2, such as Figure 4-Figure 6 As shown, the frame is provided with two groups of outer support frames, one end of the pull belt is connected to the tension cylinder, and the other end is wound around the hollow log closest to the tension cylinder, the distance The hollow log far away from the tensioning oil cylinder is connected with the frame after one week. The rest of the features are the same as in Embodiment 1 and will not be repeated here.

Embodiment 3

[0045] Example 3, such as Figure 7 As shown, a plurality of said tensioning oil cylinders are staggeredly arranged on both sides of said frame. A group of outer supporting frames are arranged on the frame.

[0046] Such as Figure 8 As shown, the present invention also discloses a method for making circles of a drawstring type round stitching machine, using the drawstring type round stitching machine as described above, the steps are as follows:

[0047] 1) planing, milling, and pouring glue on multiple fan-shaped bodies required by the hollow log;

[0048] 2) Place a single fan-shaped body on the outer support frame, and then place adjacent fan-shaped bodies through the mortise and tenon structure of the fan-shaped body;

[0049] 3) When placing half of the fan-shaped bodies on the outer support frame, place the two inner support frames on the two ends of the spliced fan-shaped bodies respectively, and then continue to splice the fan-shaped bodies through the mortise an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com