Welded insulated gas cylinder

A hot gas bottle and liner technology, which is applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, ship construction details, etc., can solve problems such as gas loss, reduce gas loss, reduce the pressure and temperature in the bottle, The effect of reducing the on-frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution and provides detailed implementation and specific operation procedures, but the scope of protection of the present invention is not limited to this Examples.

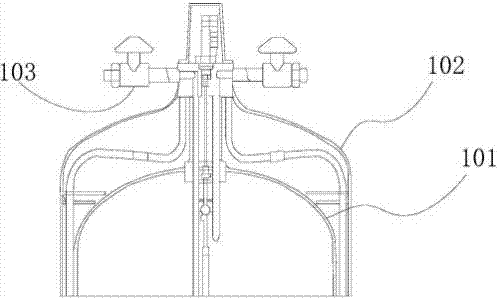

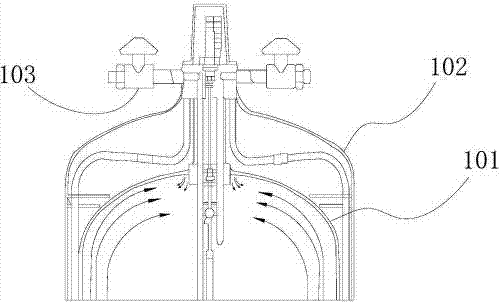

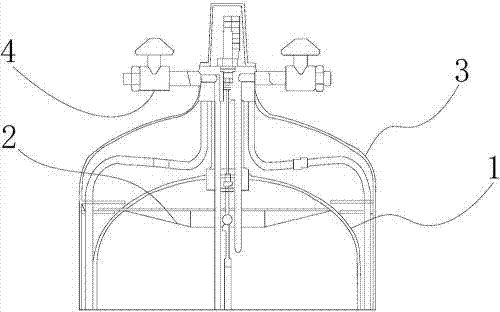

[0015] Such as image 3 As shown, a welded insulated gas cylinder includes an outer cylinder 3, an inner tank 1 and a safety valve 4, and a spoiler baffle 2 is provided on the upper part of the inner cavity of the inner tank.

[0016] The spoiler baffle 2 has a three-dimensional shape, specifically in the shape of an inverted truncated cone or an inverted cone, and its side surface and the upper bottom surface form an included angle of less than 90 degrees.

[0017] It should be noted that the purpose of setting the turbulence baffle is that when a large number of naturally vaporized gas-phase molecules rise along the inner wall of the welded ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com