Pixel structure

A technology of pixel structure and pixel area, applied in electrical components, electric solid-state devices, circuits, etc., can solve the design problems affecting the resolution of RGB sub-pixel panels, reduce production costs and process difficulties, improve applicability, reduce The effect of the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

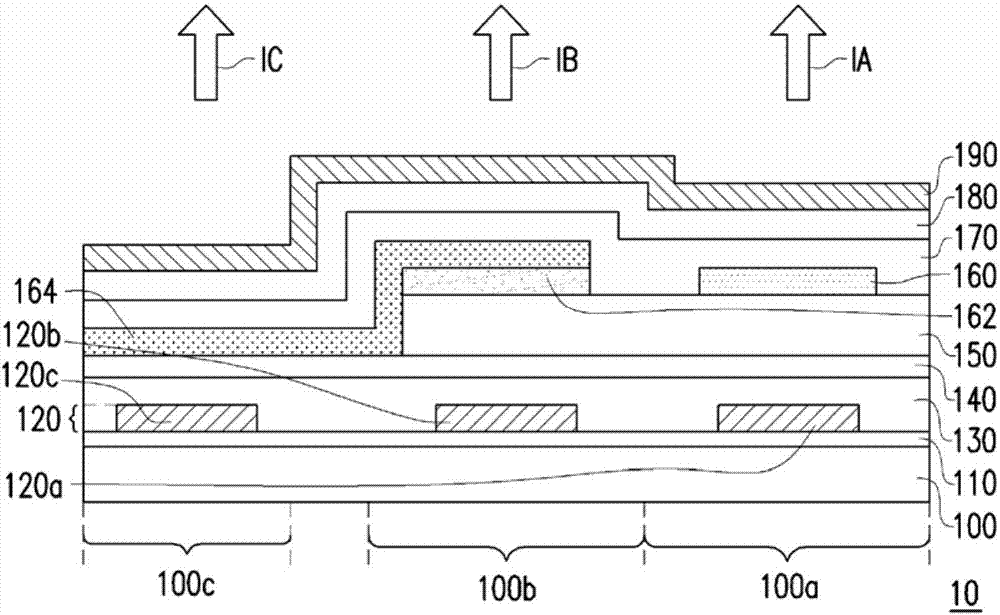

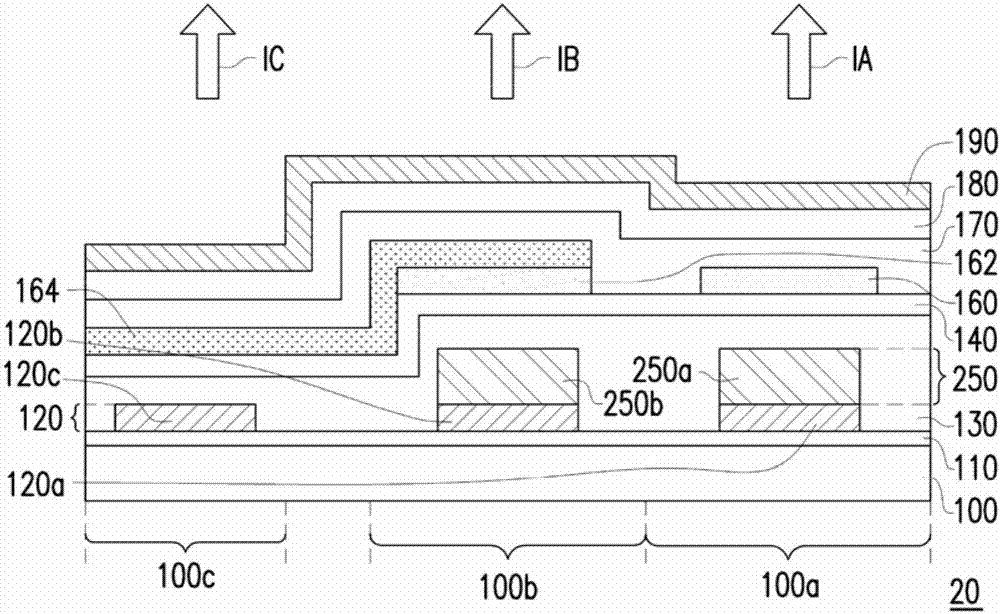

[0039] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0040] The pixel structure of the present invention can be applied in OLED display panels, for example. Based on this, although in order to describe the design of the pixel structure of the present invention in detail, the following is an example of a single pixel structure, but any person skilled in the art should understand that an organic light emitting diode display panel generally includes multiple identical or A pixel array formed by arrays of similar pixel structures. Therefore, anyone skilled in the art can understand the structure or layout of the pixel array in the OLED display panel according to the following description for a single pixel structure.

[0041] figure 1 is a schematic cross-sectional view of the pixel structure according to the first embodiment of the present invention. Please refer to figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com