Flat cable type coil cloth leftover detection device

A detection device and coil technology, applied in the direction of processing textile material equipment configuration, etc., can solve the problems of long detection distance, easy interference of detection results, unstable detection system, etc., to achieve the effect of improving the detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] The traditional cloth head detection device has a small built-in induction coil, and the strength of the detection signal is determined by the distance between the magnetic bead and the coil. The farther the distance is, the weaker the signal is, which makes the detection unstable and prone to missed detection. The invention changes the structure of the conventional cloth head detector and uses a brand-new design scheme of the induction coil. The test shows that the detection rate of the cloth head can almost reach 100%, and the detection accuracy is very high.

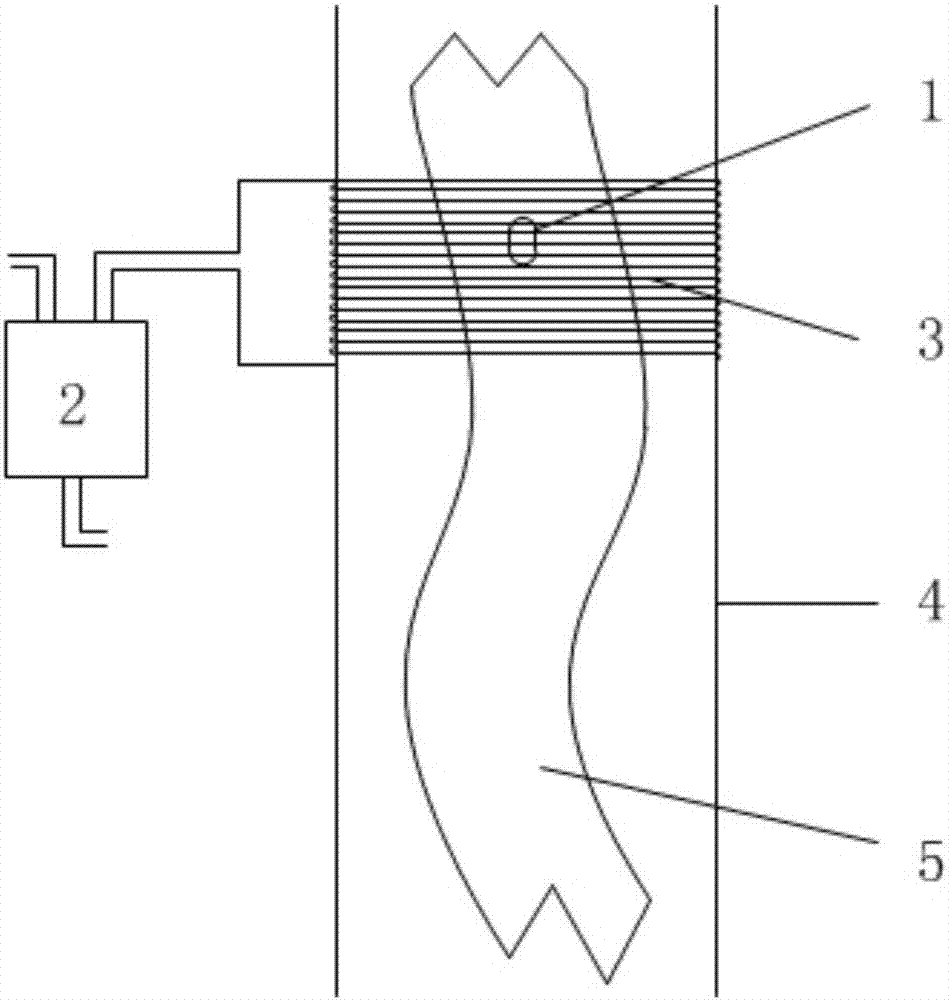

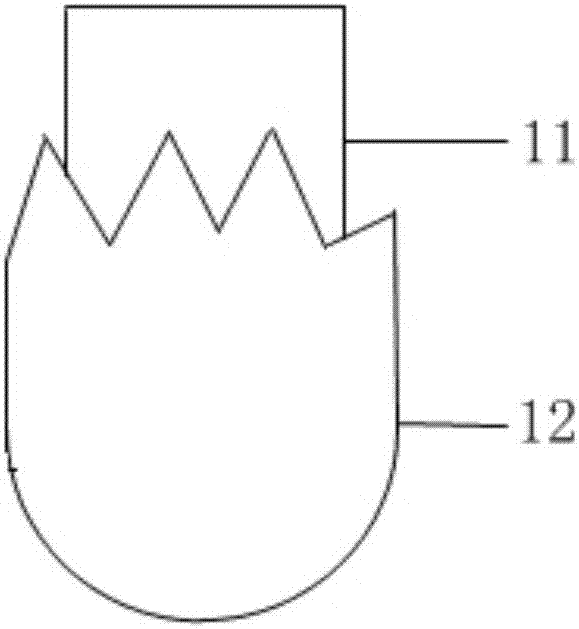

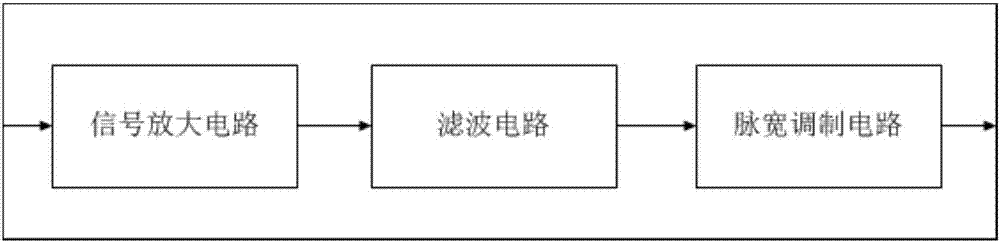

[0020] combine Figure 1 to Figure 5 , a line-type coil cloth head detection device, including a magnetic bead 1, a detection circuit 2 and an induction coil 3, the magnetic bead 1 is fixed on the cloth to be dyed, and circulates in the cloth dyeing machine together with the cloth to be dyed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com