Wear-resisting heat preservation non-slip flanged pipe fitting for small workshop

A technology for using flanges and workshops, which is applied in the field of flanged pipe fittings for wear-resistant, heat-preserving and non-slip small workshops. It can solve the problems of easy scalding of pipe walls, loose bolts, and shortened equipment service time. It is easy and difficult to assemble or maintain. The effect of falling off and not easy to slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

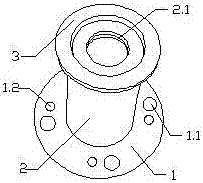

[0015] see figure 1 , the present invention is a kind of wear-resisting, heat-preserving and non-slip flanged pipe fitting for small workshops, which includes a chassis 1 and a pipe body 2, the cross-sections of the chassis 1 and the pipe body 2 are ring-shaped, and the bottom of the pipe body 2 is welded to the chassis 1 The inner diameter of the chassis 1 is provided with an anti-skid layer, the chassis 1 is provided with a large through hole 1.1, a small through hole 1.2 is provided next to the large through hole 1.1, and the inner diameter of the pipe body 2 is provided with an internal thread 2.1, the surface of the internal thread 2.1 is provided with a wear-resistant layer, the outer surface of the pipe body 2 is provided with an insulating layer, and the top end of the outer wall of the pipe body 2 is provided with a flange 3 .

[0016] After the small through hole 1.2 is set, the connection between the equipment and the equipment, and between the pipe body and the pip...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap