Improved structure of milk foaming machine

An improved structure and foaming machine technology, which is applied in the field of improved structure of milk foaming machine, can solve the problems of incomplete transmission of magnet transmission power, low working efficiency of agitator, misalignment of agitator, etc., so as to improve power transmission efficiency and improve Market competitiveness, the effect of maintaining cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

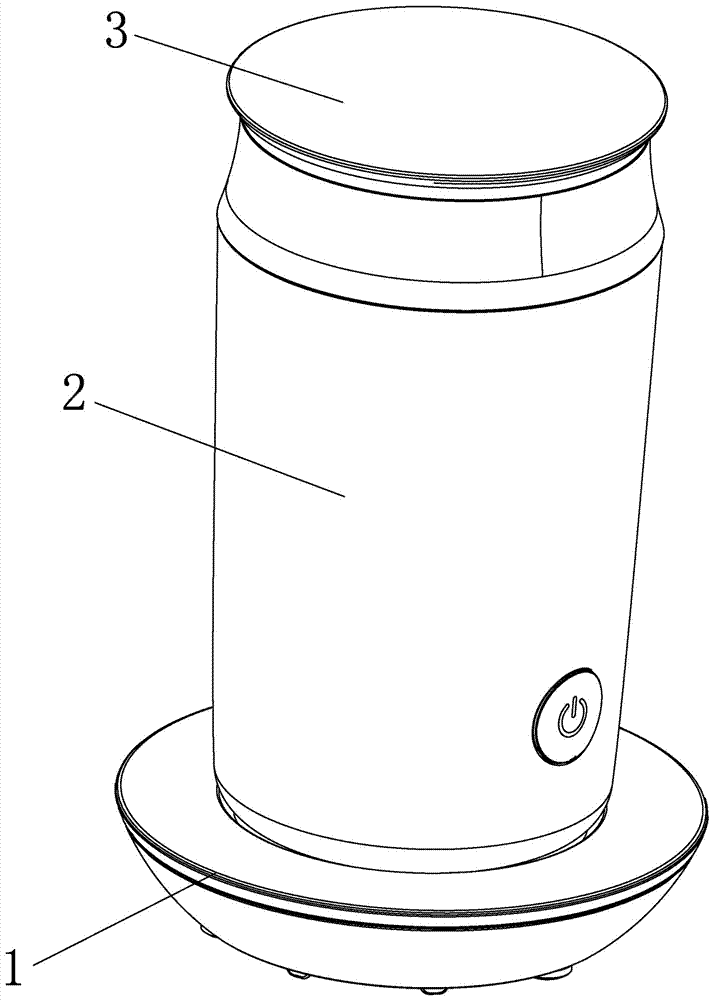

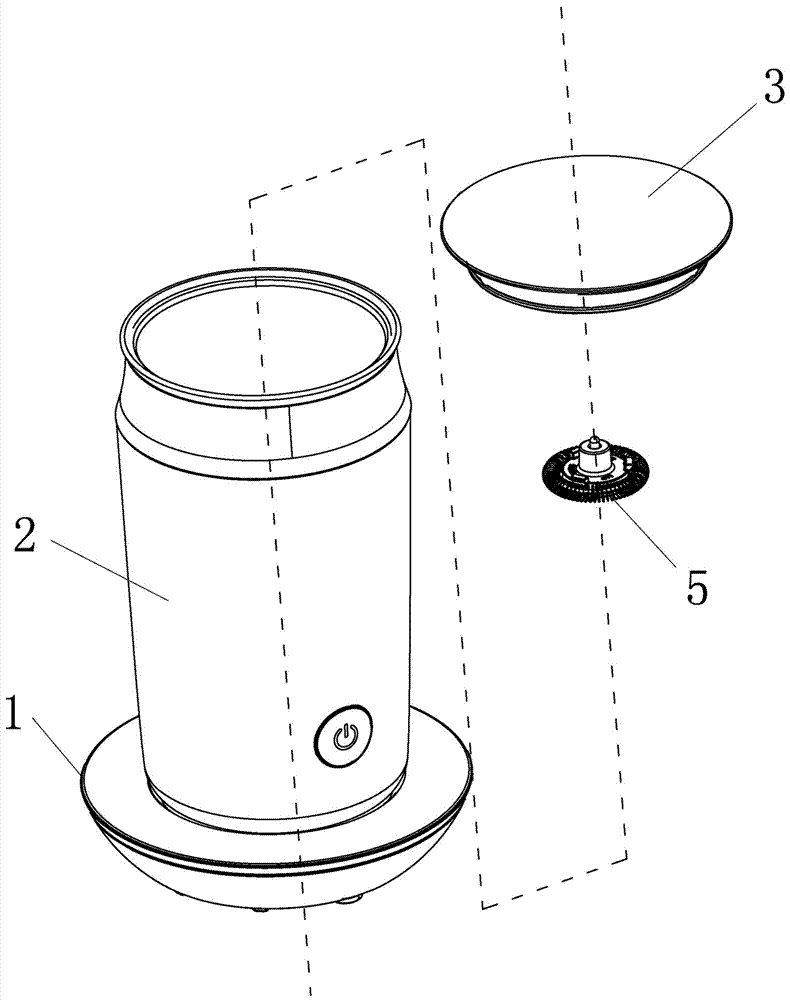

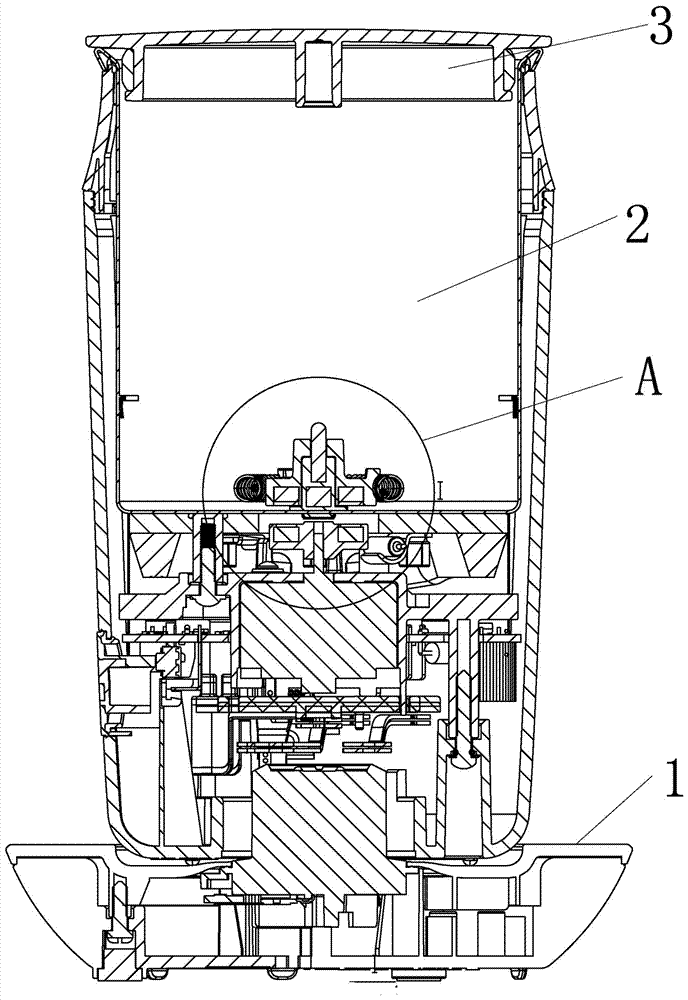

[0019] The present invention will be specifically and further described below in conjunction with the accompanying drawings. An improved structure of a milk foaming machine, which includes a base 1, a cup body 2, and a cup cover 3, the cup body 2 is detachably installed on the base 1, and the cup cover 3 is detachably installed at the mouth of the cup body 2 , the bottom of the cup body is provided with a stirring ring 5, and the outer bottom of the cup body 2 is provided with a magnetic drive device 6, which is driven by a motor 7 to rotate outside the cup body 2, and a passive magnet is arranged inside the stirring ring 5 61. When the magnetic drive device 6 rotates, the passive magnet 61 is driven by magnetic attraction to drive the stirring ring 5 to rotate at the bottom of the cup. It is characterized in that: the middle part of the stirring ring 5 is provided with a guide hole 51, and the positioning column 4 is inserted into the guide hole 51 internal connection, the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com