Variable cross section smoke throttling apparatus of desulphurization absorbing tower, and throttling method thereof

A desulfurization absorption tower and throttling device technology, applied in the field of desulfurization, can solve the problem that the flow rate of the absorption tower cannot be adjusted, and achieve the effects of increasing the gas-liquid contact rate, reducing consumption, and improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

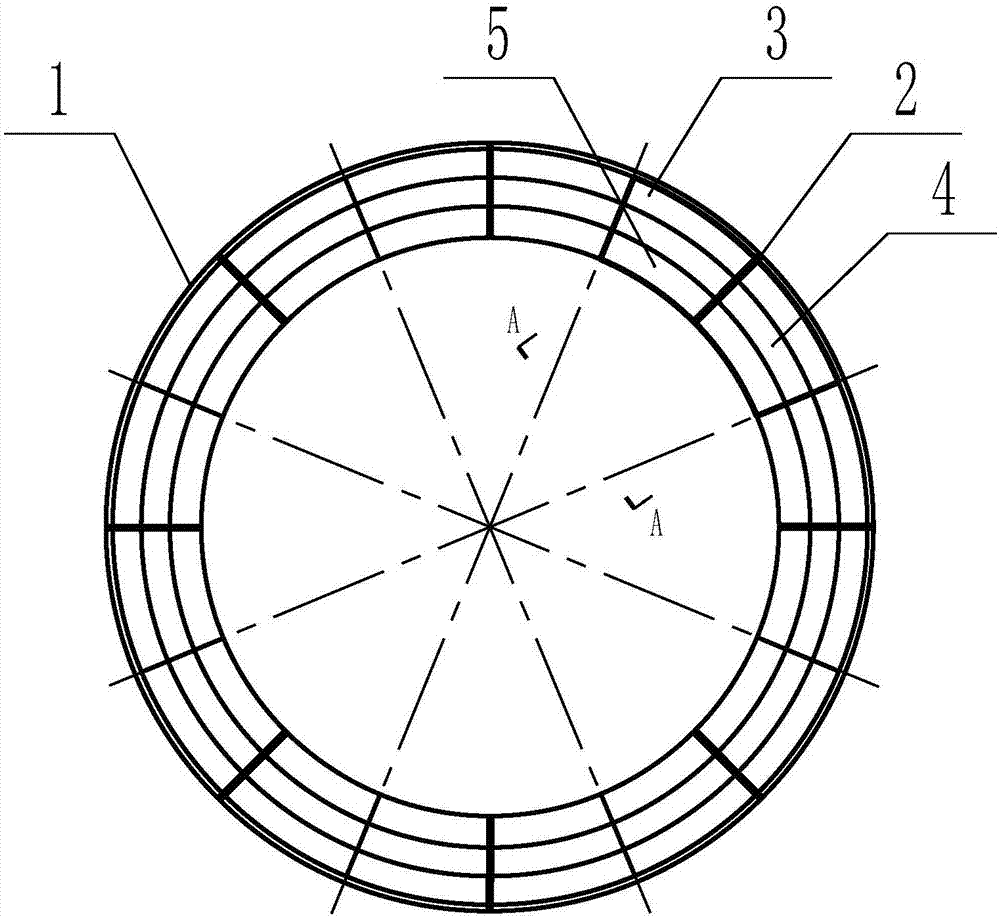

[0038] Example 1, such as figure 1 As shown, a flue gas throttling device with variable cross-section of a desulfurization absorption tower is installed inside the desulfurization absorption tower. The desulfurization absorption tower also includes several spray layers and horizontally arranged demisters installed inside the desulfurization absorption tower. Throttle devices are arranged below each spray layer and below the mist eliminator;

[0039] The throttling device is circular and placed horizontally, its outer diameter corresponds to the inner diameter of the tower wall 1 of the desulfurization absorption tower, and each throttling device includes several throttling units evenly arranged along its circumferential direction;

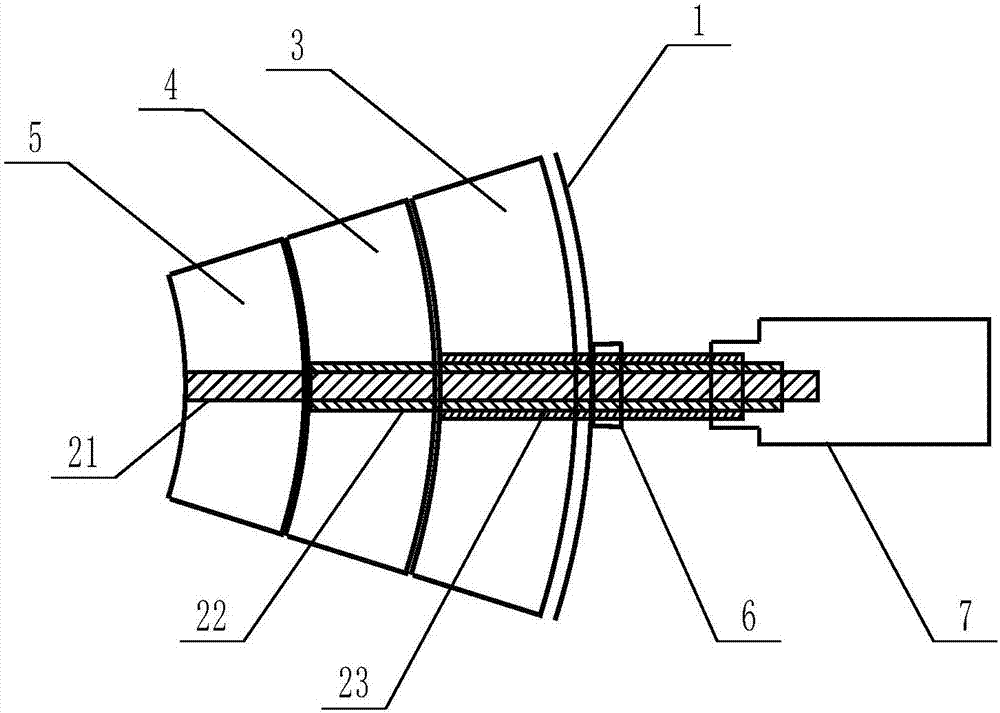

[0040] Each throttling unit includes a fan-shaped flap and a flap shaft 2 arranged along the central axis of the fan-shaped flap. One end of the flap shaft 2 passes through the tower wall 1 vertically to connect the flap shaft drive device 7, and t...

Embodiment 2

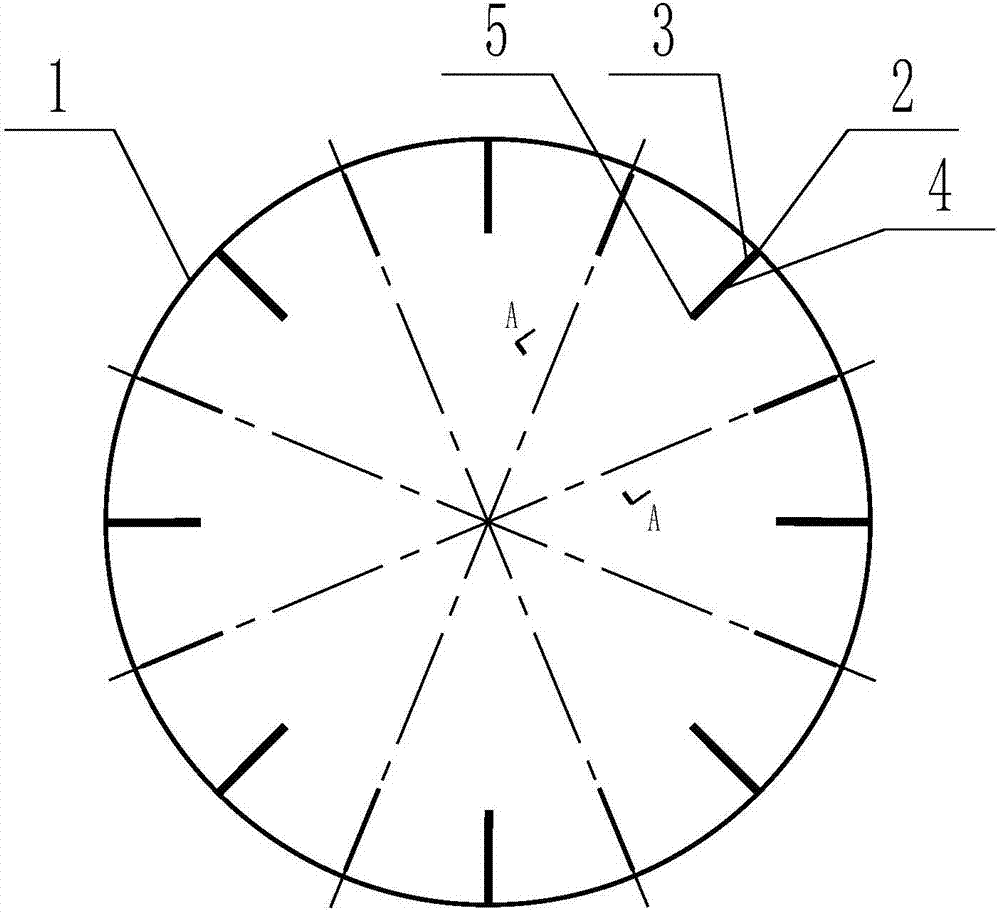

[0053] Embodiment 2, the throttling method of the flue gas throttling device with variable cross-section of the desulfurization absorption tower described in the first embodiment, includes:

[0054] Such as image 3 , 4 As shown, when the boiler load is higher than 90% of the full load, each flap shaft driving device 7 controls the rotation of all the shafts of the corresponding throttling unit, controls all the flaps to stand up, and the flow area of the desulfurization absorption tower is the largest ;

[0055] Such as Figure 5 , 6 As shown, when the boiler load is in the operating state of 80-90% of the full load, each flap shaft driving device 7 controls the first rotating shaft 23 of the corresponding throttling unit to rotate, driving the first flap 5 to be placed horizontally, and the reduction control Increase the flow area of the desulfurization absorption tower, and at the same time close part of the slurry circulation pump to reduce the flushing water volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com