Method for fine sorting and reuse of gravel asphalt waste

A technology for asphalt waste and fine separation, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as not meeting the mixing ratio design requirements, and achieve high returns, improved production efficiency, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

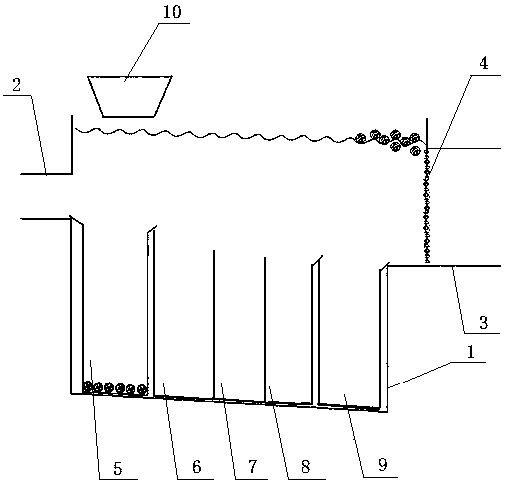

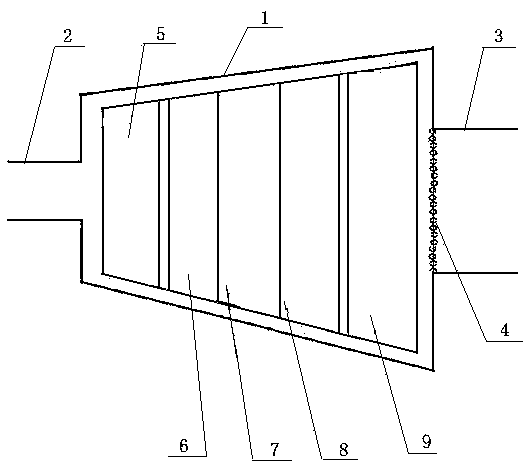

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

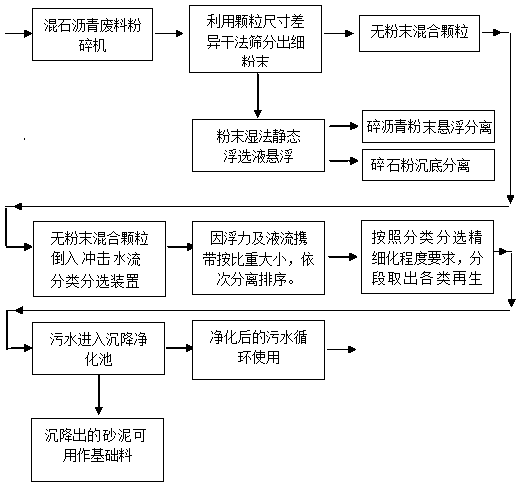

[0031] combine figure 1 , figure 2 , image 3 As shown, the fine sorting and reuse method of this gravel asphalt waste:

[0032] Use the mixed stone asphalt waste crusher to crush the mixed stone asphalt waste into uniform particles, and use the difference in particle size to dry-screen the fine powder, that is, to sieve the crushed stone powder and asphalt powder, and the rest are powder-free mixed particles ;

[0033] Crushed stone powder and crushed asphalt powder are sent into the flotation liquid tank. Based on the suspension principle of powder wet static flotation liquid, due to the difference in specific gravity, the specific gravity of crushed stone powder is 2.5, which is higher than the density of the flotation liquid and sinks into the bottom of the water. The crushed asphalt powder The specific gravity is 1.15-1.30, which is smaller than the density of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com