Movable cutting rack used for single-flow cutting equipment

A technology of cutting equipment and cutting frame, which is applied in the field of machinery manufacturing and casting, can solve the problems of inconvenient storage and transportation, easy to overturn, single function, etc., and achieve the effect of simple structure, convenient installation and heavy load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

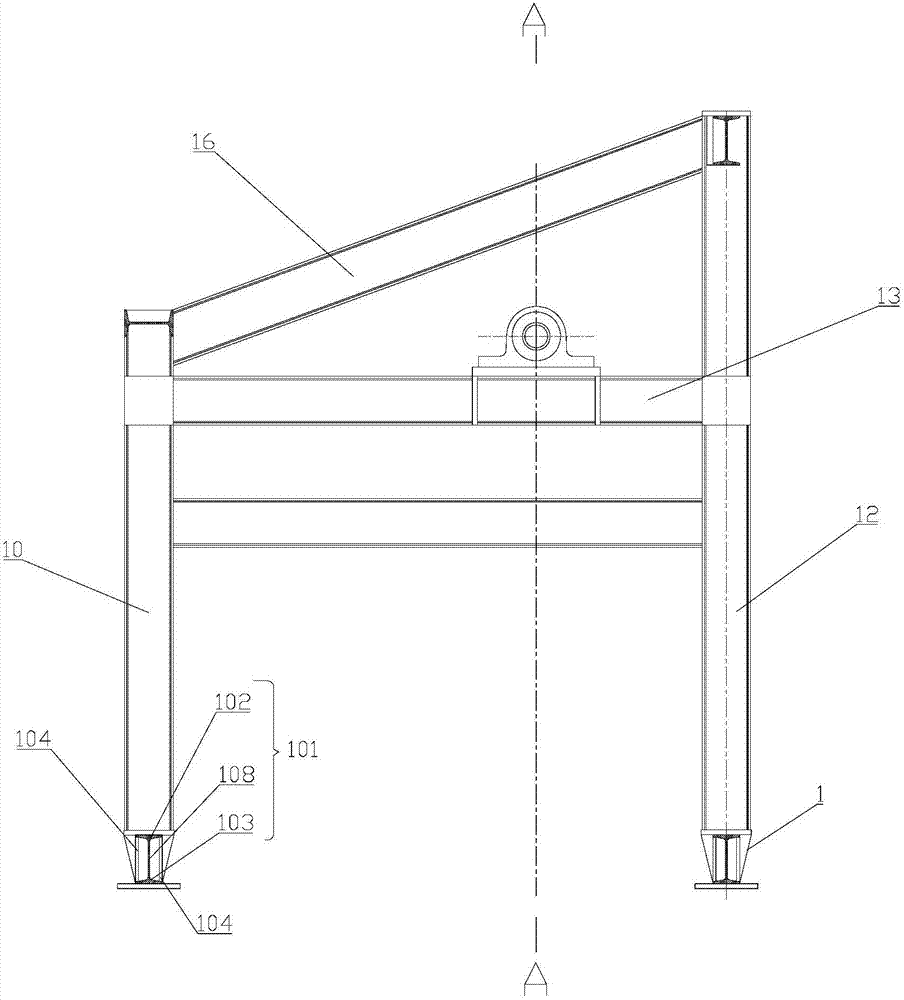

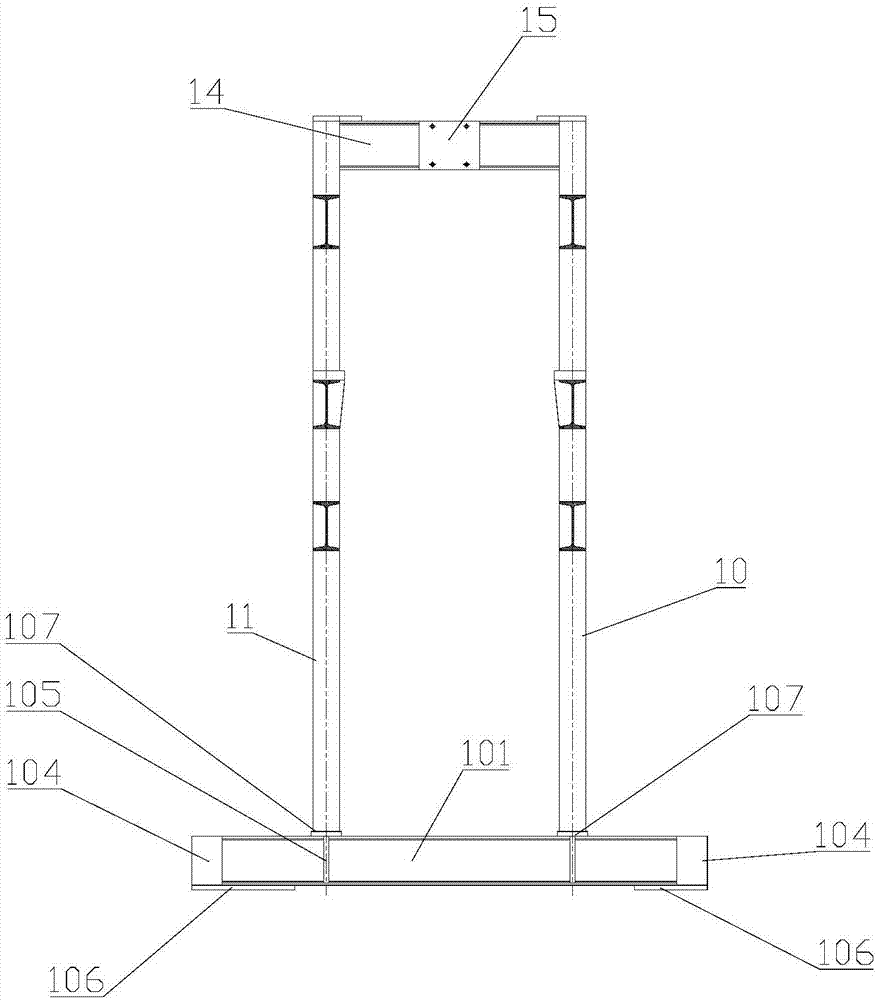

[0017] Such as Figure 1 to Figure 2 As shown, a movable cutting frame for single-flow cutting equipment provided by the present invention includes two oppositely arranged traveling wheel beams 1; the first left column 10 and the The second left column 11; the first right column 12 and the second right column arranged on another road wheel beam 1; the front beam 13 connected between the first left column 10 and the first right column 12 and the back beam connected between the second left column 11 and the second right column; the height of the first right column 12 and the second right column is greater than that of the first left column 10 and the second left column 11 Height; the top of the first right column 12 and the second right column is provided with a top connecting beam 14; the inner side of the top connecting beam 14 is provided with a cylinder block connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com