Notebook inside paper line scribing and rolling integrated machine

An all-in-one machine and notebook technology, applied in non-rotational vibration suppression, metal processing, etc., can solve the problems of high cost, difficult production, complex structure, etc., and achieve the effect of low cost, scientific and reasonable structural design, and easy assembly and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

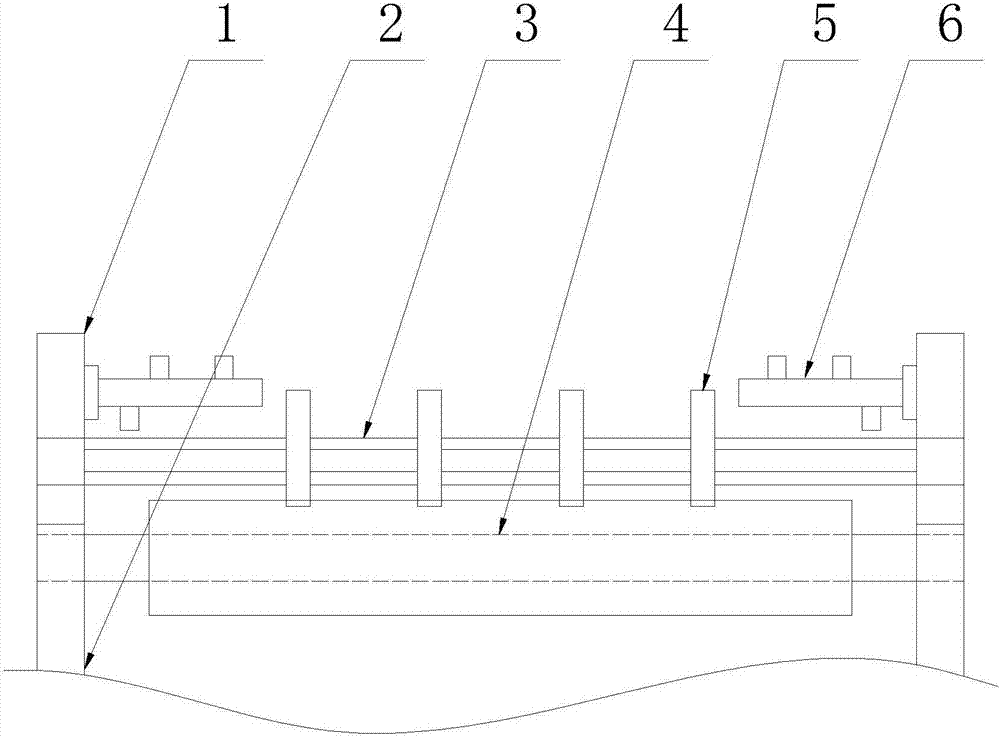

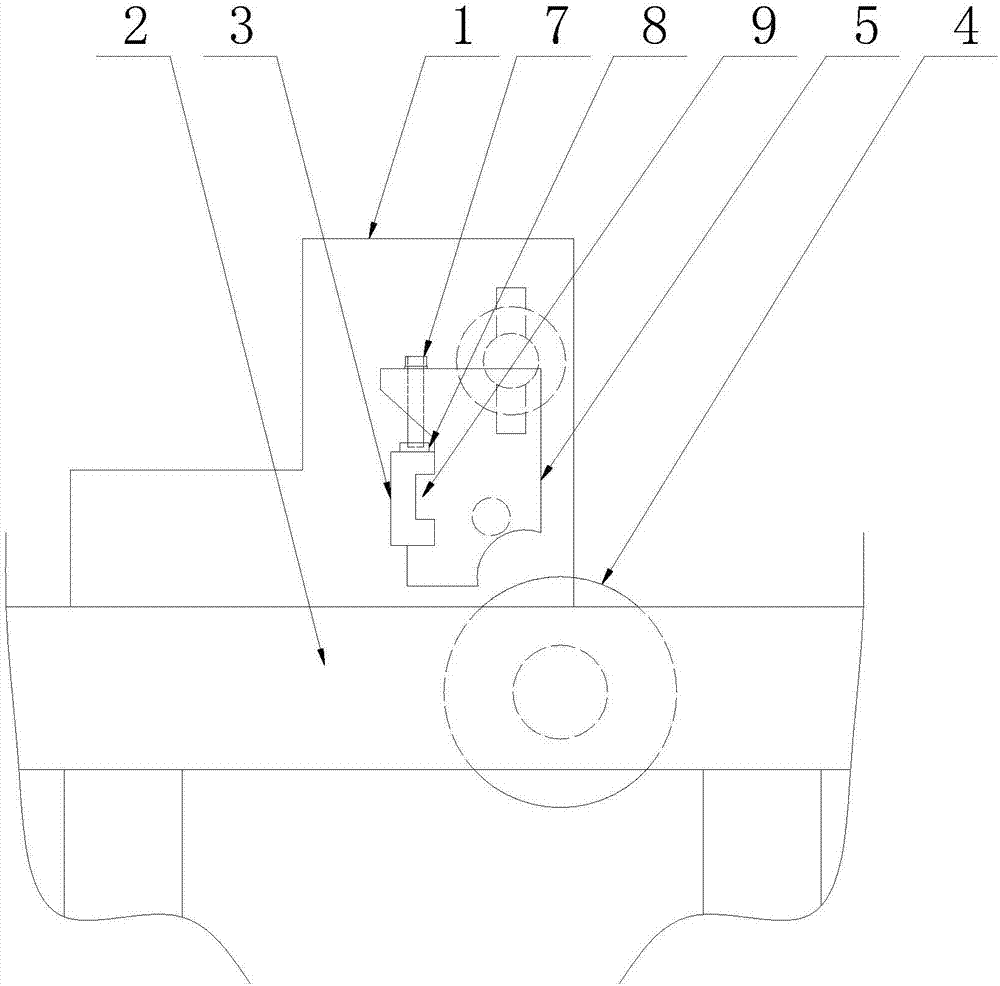

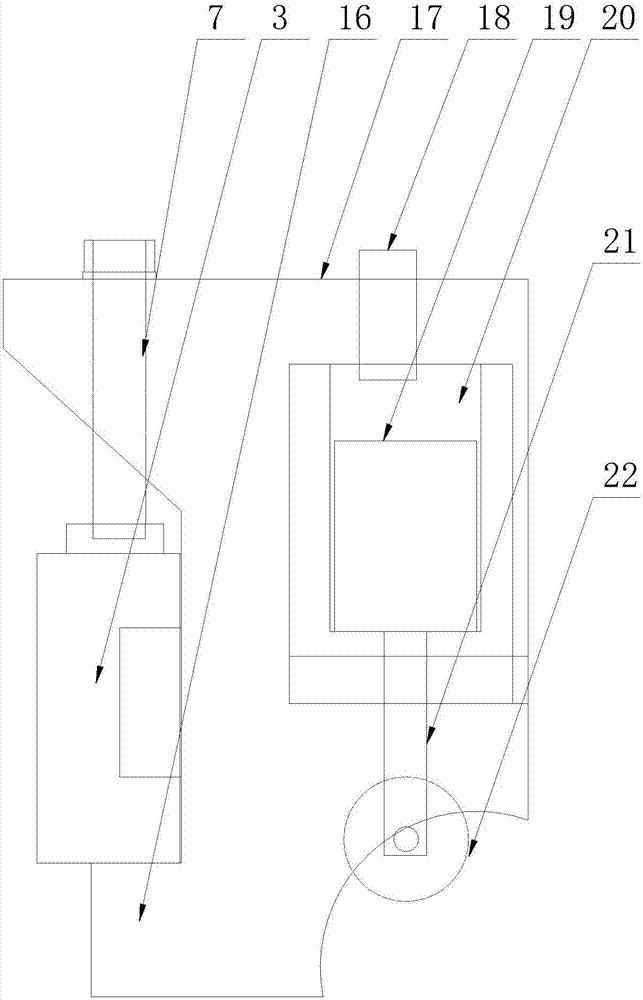

[0024] An all-in-one machine for scribing and rolling notebook inner pages, including a scribing machine, and its innovation lies in that it also includes a scribing device, and the scribing device is arranged on the scribing machine. The scribing machine is used to scribe and print grid lines on the inner pages of notebooks, and the line rolling device is used to punch holes on multiple notebook inner pages to make tear lines.

[0025] The rolling device includes a supporting positioning part, a tearing line puncher 5, and a pneumatic driving part. The supporting part is arranged on the marking machine, and the tearing line punching machine and the pneumatic driving part are all arranged on the supporting part. The supporting positioning pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com