A functional aggregate used to improve the crack resistance of concrete

A concrete and anti-cracking technology, which is applied in the field of functional aggregates to improve the cracking resistance of concrete, can solve the problems that the driving force of shrinkage and cracking cannot be controlled at the same time, and reduce the driving force of shrinkage and cracking, so as to achieve low comprehensive anti-cracking cost and reduce cracking risk, the effect of improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix tap water and ethanol solution at a volume of 95:5 to prepare 20kg of solvent, adjust the pH value of the solvent to about 4.0 by slowly adding acetic acid dropwise, then slowly add 20g of KH570 dropwise, stir until the solution is uniform and transparent, and prepare the mass concentration 0.1% coupling agent solution. Select shale light and fine aggregates with a particle size of 0-5mm, and its dry apparent density is 1410kg / m 3 , 24h water absorption rate is 11.9%. Weigh 8kg of the light aggregate and place it in the silane coupling agent solution, soak it at 20°C for 24 hours, filter it, and continue to stand at 20°C for 24 hours to obtain a functional aggregate that can improve the crack resistance of concrete.

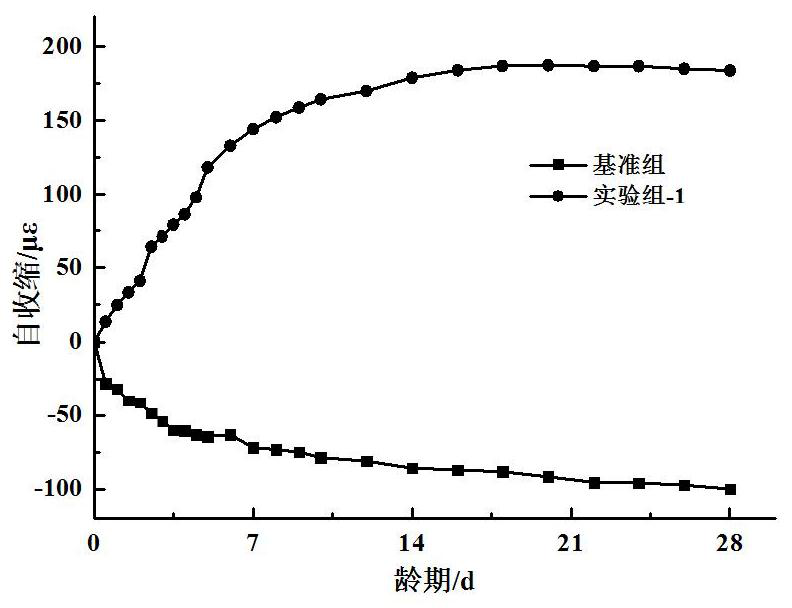

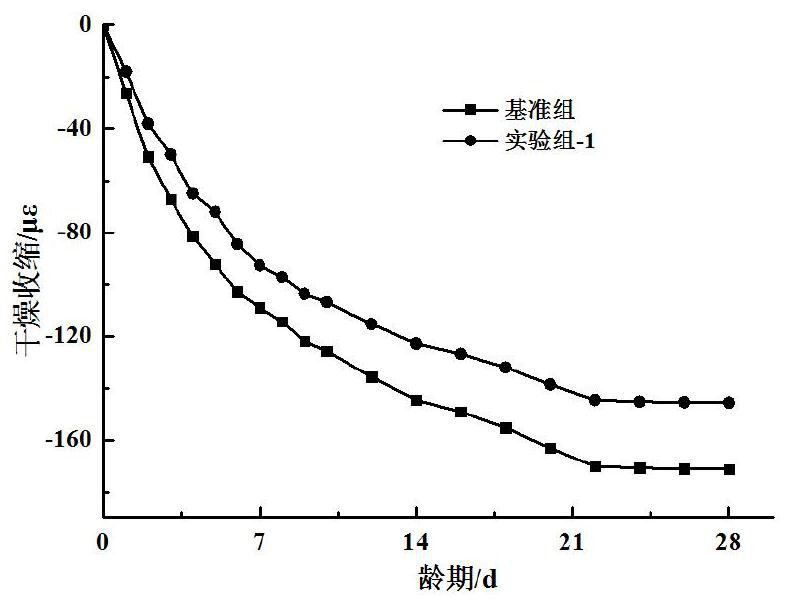

[0039] Concrete was prepared according to the concrete mix ratio shown in Table 1, in which the functional aggregate volume of the experimental group was 10%, and the sand was replaced by an equal volume, and the compressive strength of the concrete w...

Embodiment 2

[0048] Mix tap water and ethanol solution at a volume of 90:10 to prepare 20kg of solvent, adjust the pH value of the solvent to about 4.0 by slowly adding acetic acid dropwise, then slowly add 4g of KH570 dropwise, stir until the solution is uniform and transparent, and prepare the mass concentration 0.02% coupling agent solution. Select shale light and fine aggregates with a particle size of 0-5mm, and its dry apparent density is 1150kg / m 3 , 24h water absorption rate is 22.7%. Weigh 8kg of the light aggregate and place it in a silane coupling agent solution, soak it at 30°C for 18 hours, filter it, and continue to stand at 30°C for 18 hours to obtain a functional aggregate that can improve the crack resistance of concrete.

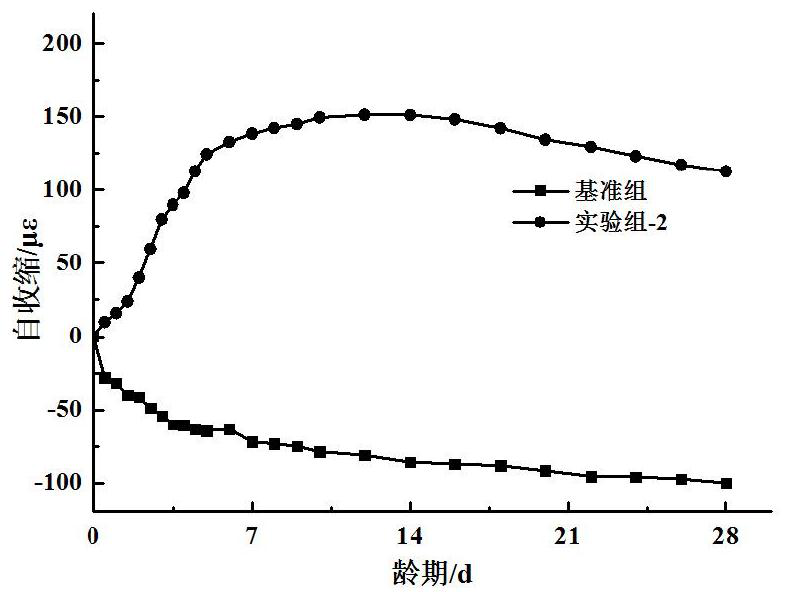

[0049] Concrete was prepared according to the concrete mix ratio shown in Table 3, in which the functional aggregate volume of the experimental group was 5%, and the sand was replaced by an equal volume, and the compressive strength of the concrete was...

Embodiment 3

[0057] Mix tap water and ethanol solution at a volume of 95:5 to prepare 50kg of solvent, adjust the pH value of the solvent to about 4.0 by slowly adding acetic acid dropwise, then slowly add 75g of KH560 dropwise, stir until the solution is uniform and transparent, and prepare the mass concentration 0.15% coupling agent solution. Select shale light and fine aggregate with a particle size of 5-20mm, and its dry apparent density is 1860kg / m 3 , 24h water absorption rate is 5.0%. Weigh 15kg of the light aggregate and place it in a silane coupling agent solution, soak it at 40°C for 12 hours, filter it, and continue to stand at 40°C for 12 hours to obtain a functional aggregate that can improve the crack resistance of concrete.

[0058] Concrete was prepared according to the concrete mix ratio shown in Table 5, in which the functional aggregate volume of the experimental group was 15%, and the equal volume replaced gravel, and the compressive strength of the concrete was tested...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com