Zirconium oxide ceramic coloring method and preparation method of mobile communication equipment shell

A technology of mobile communication equipment and zirconia ceramics, which is applied in the field of ceramic products, can solve the problems that it is difficult to produce bright colored zirconia ceramics, and achieve the effect of stable color, low processing difficulty and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

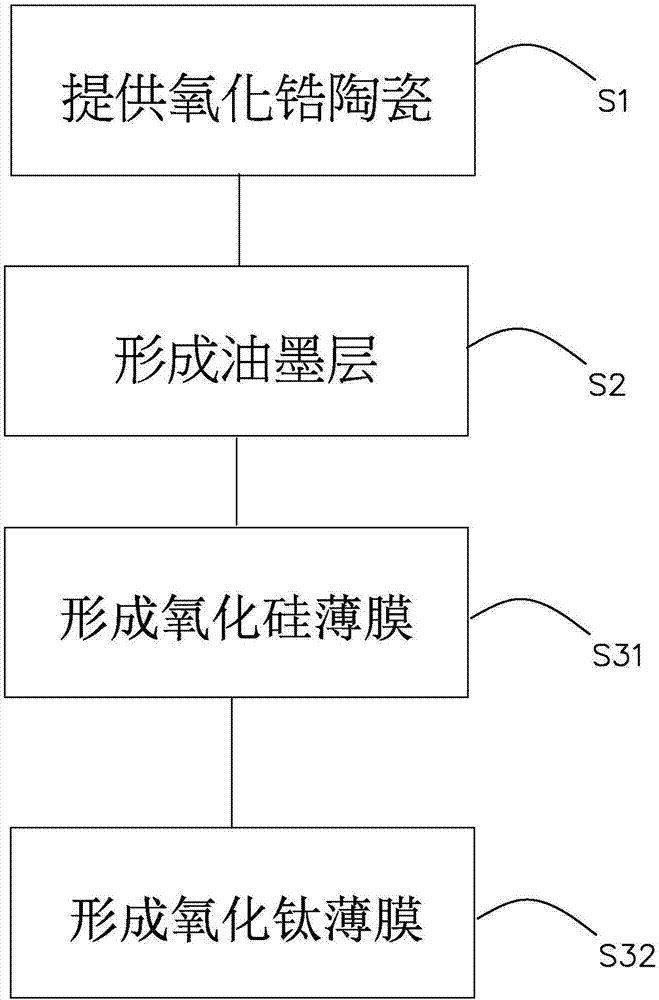

[0022] refer to figure 1 As shown, the present invention provides a method for coloring zirconia ceramics, which has the beneficial effects of bright color and stable color.

[0023] Concrete coloring method comprises the following steps:

[0024] S1: Provide transparent or translucent zirconia ceramics;

[0025] S2: spraying ink on the zirconia ceramics and heating and drying at 70-80°C to form an ink layer, specifically, spraying ink on the front or back of the zirconia ceramics provided in step S1, or spraying ink on both the front and back;

[0026] S3: forming a protective film with a thickness of 5-10 μm on the ink layer by magnetron sputtering, specifically, including the following steps:

[0027] S31: Form SiO on the ink layer by magnetron sputtering 2 (silicon dioxide) film;

[0028] S32: On SiO 2 Magnetron sputtering on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com