Formula for making antibacterial PVC sole

A PVC resin and formula technology, applied in the field of shoe soles, can solve the problem of low radiation protection function of shoe materials, and achieve the effects of avoiding bacterial infection, high wear resistance, and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

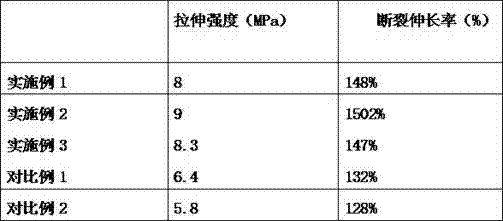

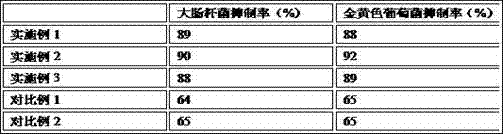

Examples

Embodiment 1

[0078] Weigh 85 parts of PVC resin, 22 parts of epoxidized natural rubber, 3 parts of cinnamon extract, 3 parts of silica airgel, 3 parts of crosslinking agent, 1.5 parts of stabilizer, 1 part of lubricant, plasticizer 22 parts of additive, 1.2 parts of metal salt stabilizer, 7 parts of anti-radiation powder, 8 parts of bamboo fiber superfine powder, 5 parts of inorganic rigid particles, and 3 parts of SEBS. Mix the above ingredients evenly at a temperature of 85 °C. The uniformly mixed material is pressed into tablets after banburying to make antibacterial and stretchable PVC sole material.

Embodiment 2

[0080] Weigh 90 parts of PVC resin, 26 parts of epoxidized natural rubber, 4 parts of cinnamon extract, 3.5 parts of silica airgel, 3.5 parts of crosslinking agent, 2 parts of stabilizer, 1.5 parts of lubricant, plasticizer 25 parts of anti-radiation agent, 2 parts of metal salt stabilizer, 8 parts of anti-radiation powder, 11 parts of bamboo fiber superfine powder, 6 parts of inorganic rigid particles, 3.5 parts of SEBS, and mix the above ingredients evenly at a temperature of 83 ° C. The uniformly mixed material is pressed into tablets after banburying to make antibacterial and stretchable PVC sole material.

Embodiment 3

[0082] Weigh 95 parts of PVC resin, 28 parts of epoxidized natural rubber, 5 parts of cinnamon extract, 4 parts of silica airgel, 4 parts of crosslinking agent, 2.5 parts of stabilizer, 1.8 parts of lubricant, plasticizer 28 parts of anti-radiation agent, 2.8 parts of metal salt stabilizer, 9 parts of anti-radiation powder, 12 parts of bamboo fiber superfine powder, 7 parts of inorganic rigid particles, and 4 parts of SEBS. Mix the above ingredients evenly at a temperature of 88 ° C. The uniformly mixed material is pressed into tablets after banburying to make antibacterial and stretchable PVC sole material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com