Bridge construction equipment

A technology for bridge construction and equipment, applied in clay preparation devices, roads, unloading devices, etc., can solve the problems of high purchase capital, time-consuming and laborious, inconvenient to use, etc., and achieve the effect of increasing the infusion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

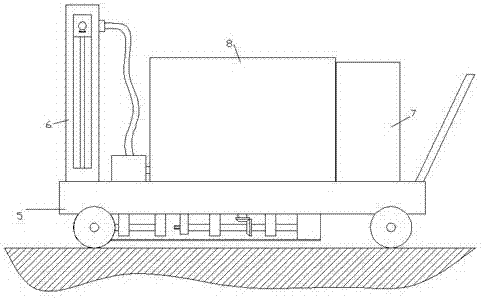

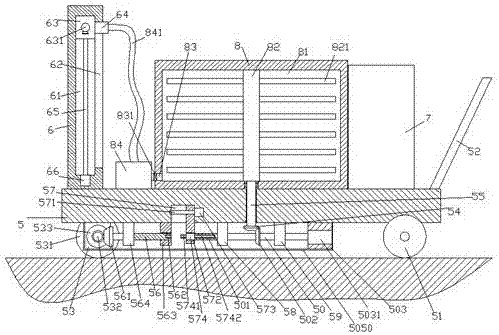

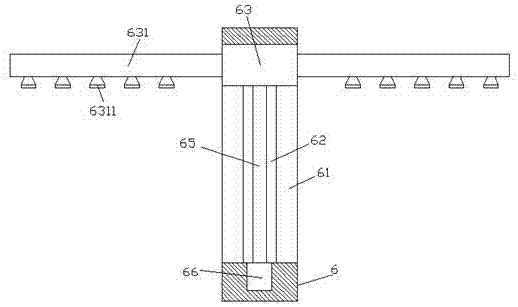

[0024] like Figure 1-Figure 5As shown, a bridge construction equipment of the present invention includes a frame body 5 and a stirring box 8 fixed at the middle position of the top of the frame body 5, and a fixed device on the top end surface of the frame body 5 on the left side of the stirring box 8 There is an infusion member 6, and the top end surface of the frame body 5 on the right side of the stirring box 8 is fixedly provided with an electrification member 7, and the inner middle of the frame body 5 is provided with a first revolving pin shaft 55 which is rotationally fitted and connected. The extension section at the bottom of the first rotating pin shaft 55 grows out of the end face of the bottom of the frame body 5 and is fixedly provided with a first cone wheel 54 at the end. The left and right sides of the first cone wheel 54 are respectively provided with a top and the frame body 5 The first pole 58 and the second pole 59 that are fixedly connected to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com