Intelligent vibration damping device based on SMA variable-rigidity spring and working process

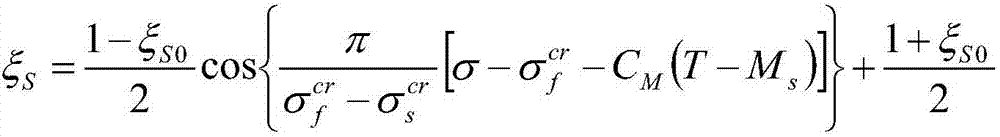

A variable stiffness spring and intelligent damping technology, applied in the design characteristics of spring/shock absorber, functional characteristics of spring/shock absorber, spring/shock absorber, etc., can solve the problem of no temperature-vibration feedback adjustment mechanism, no Considering the temperature-sensitive characteristics of SMA, the stiffness of the SMA damper and the non-adjustable energy dissipation capacity, etc., it achieves the effects of obvious vibration reduction effect, small space occupation and excellent vibration reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with the accompanying drawings, the specific implementation methods and precautions of the present invention will be described in detail.

[0026] Vibration feedback mechanism based on sensor technology

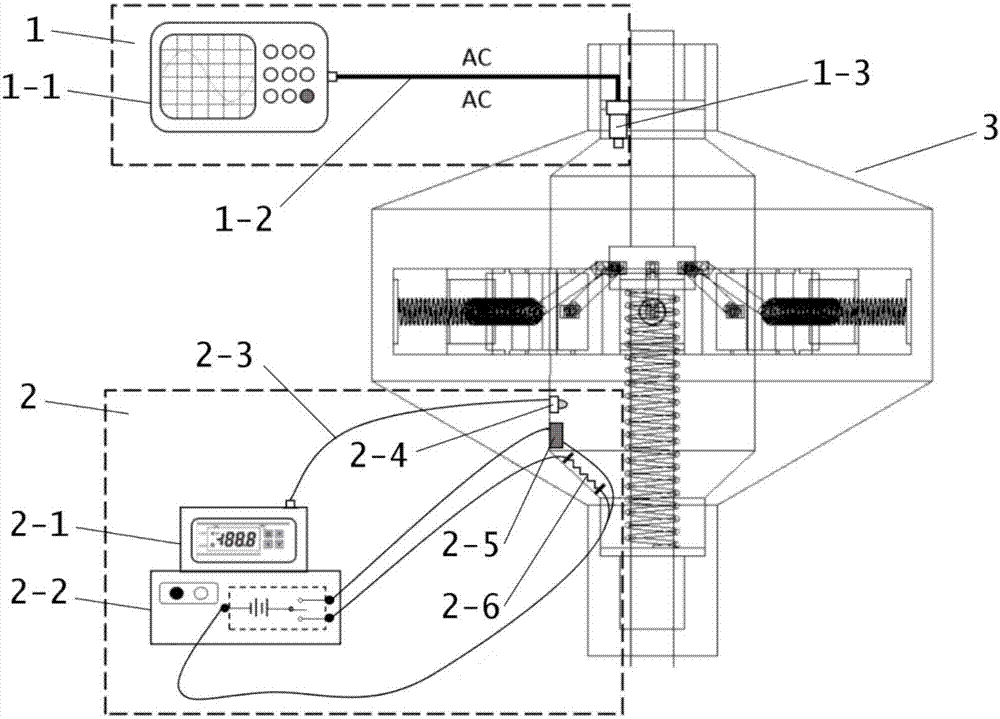

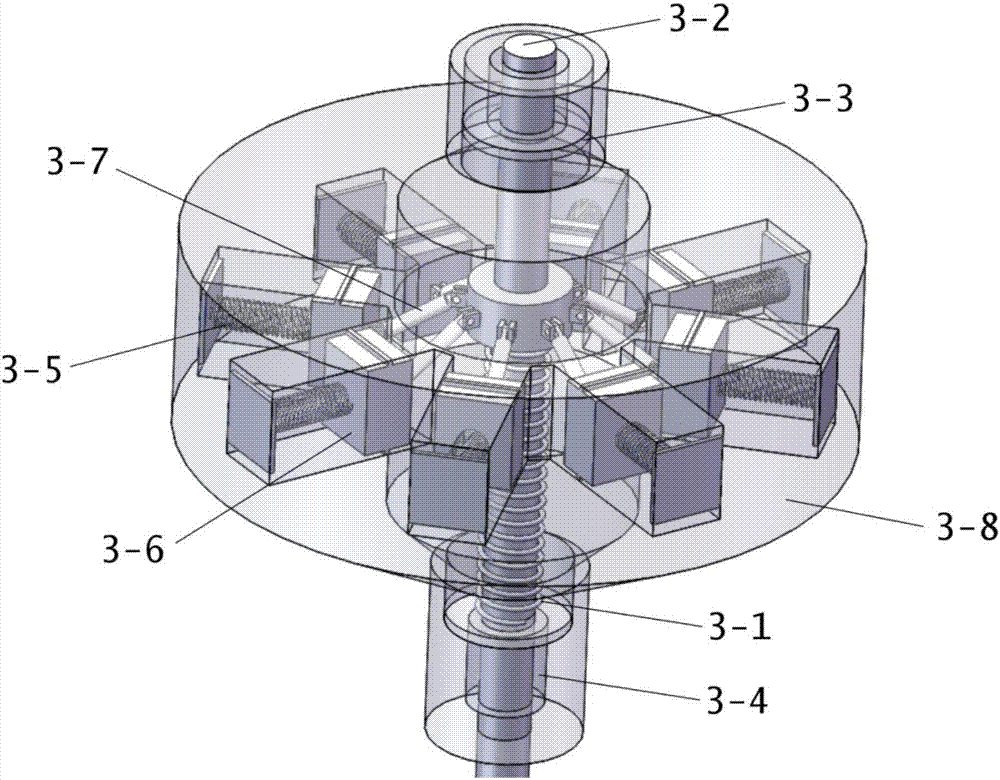

[0027] The principle of a novel intelligent damping device based on the SMA variable stiffness spring of the present invention is as attachedfigure 1 As shown, it is composed of a vibration monitoring part 1, a working chamber temperature control part 2 and a shock absorber main part 3. Vibration monitoring part 1 involves vibration sensing technology, which is composed of oscilloscope 1-1, cable 1-2 and sensor probe 1-3. Its working principle is: the raised part of sensor probe 1-3 and central moving axis 3-2 There is a certain distance, when the main part of the shock absorber 3 starts to vibrate under the action of external disturbance, the convex part of the central moving axis 3-2 will move up and down accordingly, and the distance between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com