Refrigeration tower of superconduction iron remover and control method

A technology of iron remover and superconductivity, which is applied in the field of cooling tower and control of superconducting iron remover, which can solve the problems that the cooling tower is easy to freeze and affects the work of the cooling tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

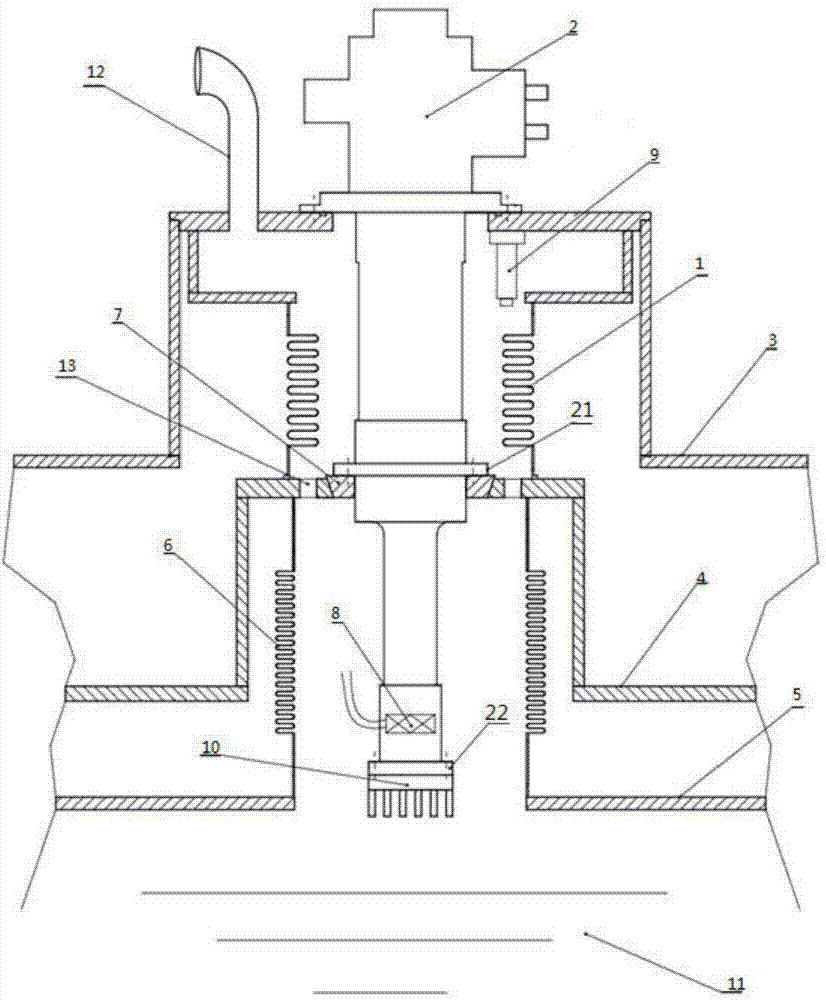

[0028] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings. It is only intended to describe the specific implementation of the present invention in detail, and does not impose any limitation on the present invention, and the scope of protection of the present invention shall be determined by the claims.

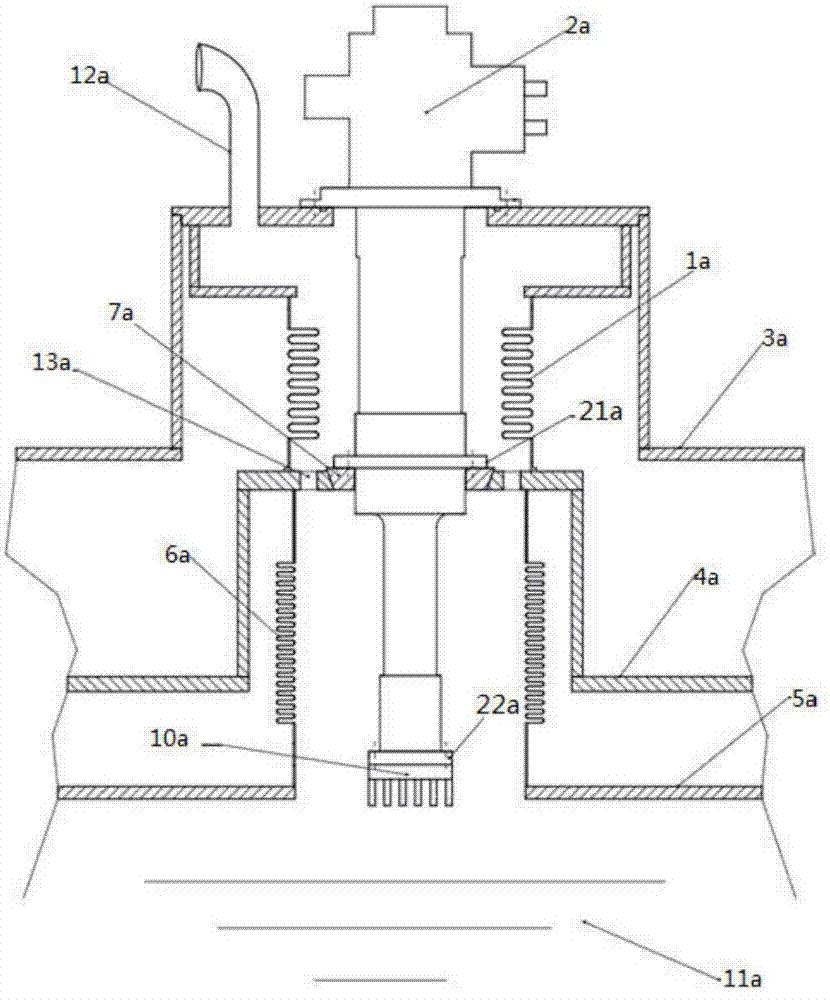

[0029] refer to figure 2 , the present invention proposes a refrigeration tower of a superconducting iron remover, comprising:

[0030] Refrigeration tower body and heating control device;

[0031] The refrigeration tower body at least includes a refrigerator 2, an outer cylinder 3 used in conjunction with the refrigerator 2, and a low-temperature liquid helium Dewar 5, and the heating control device is partially or completely installed on the refrigeration tower body;

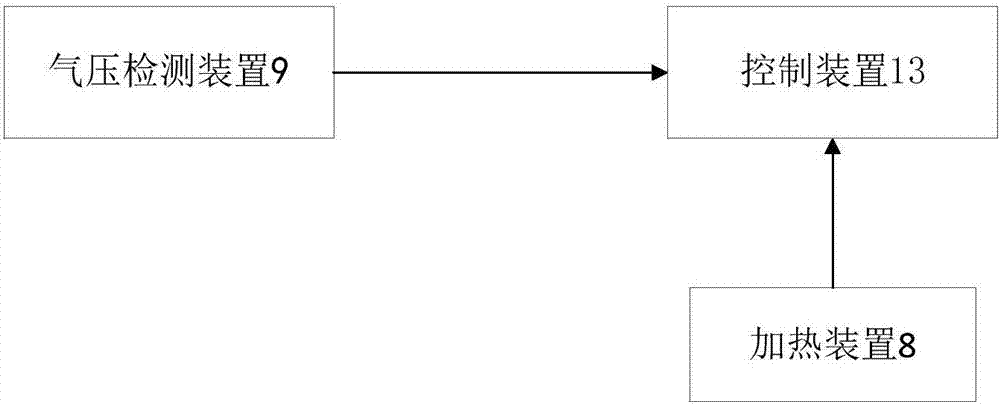

[0032] The heating control device detects the pressure value in the cryogenic liquid helium Dewar 5, and if the detected press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com