Preparation method for TiO2/Sn3O4 negative electrode material for lithium ion battery

A technology of tritin tetroxide and lithium-ion batteries, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as low capacity and poor cycle performance, and alleviate volume changes , good cycle performance, considerable capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

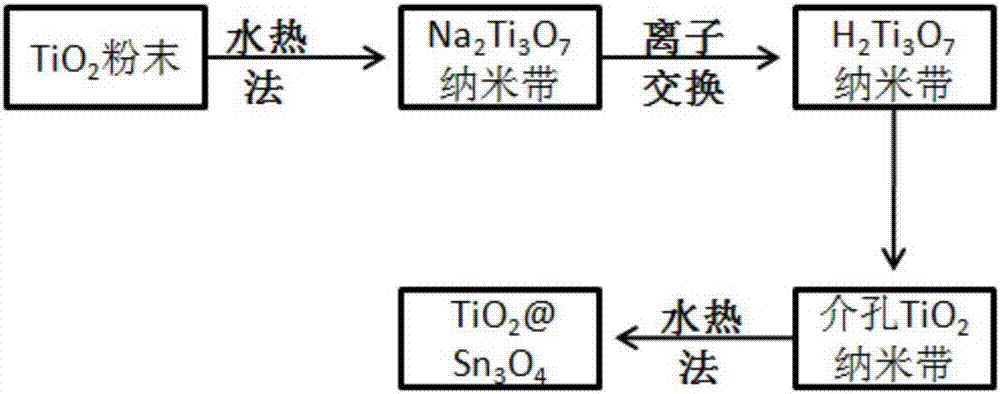

[0040] (1) A certain amount of commercial TiO 2 The powder is added to a molar concentration of 10±0.1molL -1 NaOH aqueous solution, stirred until completely dissolved; among them, TiO 2 The molar ratio of powder to NaOH is 1:80;

[0041] (2) Place the solution obtained in step (1) in a hydrothermal kettle with a certain volume and heat it up to 180°C at a heating rate of 8-10°C / min, and naturally cool to room temperature after reacting for 24 hours; wherein the solution and the hydrothermal kettle The volume ratio is 80:100;

[0042] (3) Wash the solid in the product obtained in step (2) several times with deionized water, place the washed product in a vacuum oven at 50-60°C and dry to constant weight, and grind to obtain Na 2 Ti 3 o 7 nanobelt;

[0043] (4) adding the product obtained in step (3) to a molar concentration of 1 ± 0.1molL -1 In aqueous HCl solution, stirred for 24h; where, Na 2 Ti 3 o 7 The volume ratio of nanobelts and HCl aqueous solution is 1:3.

...

Embodiment 2

[0055] (1) A certain amount of commercial TiO 2 The powder is added to a molar concentration of 10±0.1molL -1 NaOH aqueous solution, stirred until completely dissolved; among them, TiO 2 The molar ratio of powder to NaOH is 1:80;

[0056] (2) Place the solution obtained in step (1) in a hydrothermal kettle with a certain volume and heat it up to 180°C at a heating rate of 8-10°C / min, and naturally cool to room temperature after reacting for 24 hours; wherein the solution and the hydrothermal kettle The volume ratio is 80:100;

[0057] (3) Wash the solid in the product obtained in step (2) several times with deionized water, place the washed product in a vacuum oven at 50-60°C and dry to constant weight, and grind to obtain Na 2 Ti 3 o 7 nanobelt;

[0058] (4) adding the product obtained in step (3) to a molar concentration of 1 ± 0.1molL -1 In aqueous HCl solution, stirred for 24h; where, Na 2 Ti 3 o 7 The volume ratio of nanobelts and HCl aqueous solution is 1:3.

...

Embodiment 3

[0068] (1) A certain amount of commercial TiO 2 The powder is added to a molar concentration of 10±0.1molL -1 NaOH aqueous solution, stirred until completely dissolved; among them, TiO 2 The molar ratio of powder to NaOH is 1:80;

[0069] (2) Place the solution obtained in step (1) in a hydrothermal kettle with a certain volume and heat it up to 180°C at a heating rate of 8-10°C / min, and naturally cool to room temperature after reacting for 24 hours; wherein the solution and the hydrothermal kettle The volume ratio is 80:100;

[0070] (3) Wash the solid in the product obtained in step (2) several times with deionized water, place the washed product in a vacuum oven at 50-60°C and dry to constant weight, and grind to obtain Na 2 Ti 3 o 7 nanobelt;

[0071] (4) adding the product obtained in step (3) to a molar concentration of 1 ± 0.1molL -1 In aqueous HCl solution, stirred for 24h; where, Na 2 Ti 3 o 7 The volume ratio of nanobelts and HCl aqueous solution is 1:3.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com