Preparation method of titanium dioxide/tritin tetroxide negative electrode material for lithium ion battery

A technology of tritin tetroxide and lithium ion batteries, which is applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of poor cycle performance and low capacity, and achieve good cycle performance. , Relieve volume change, avoid the effect of capacity decay too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

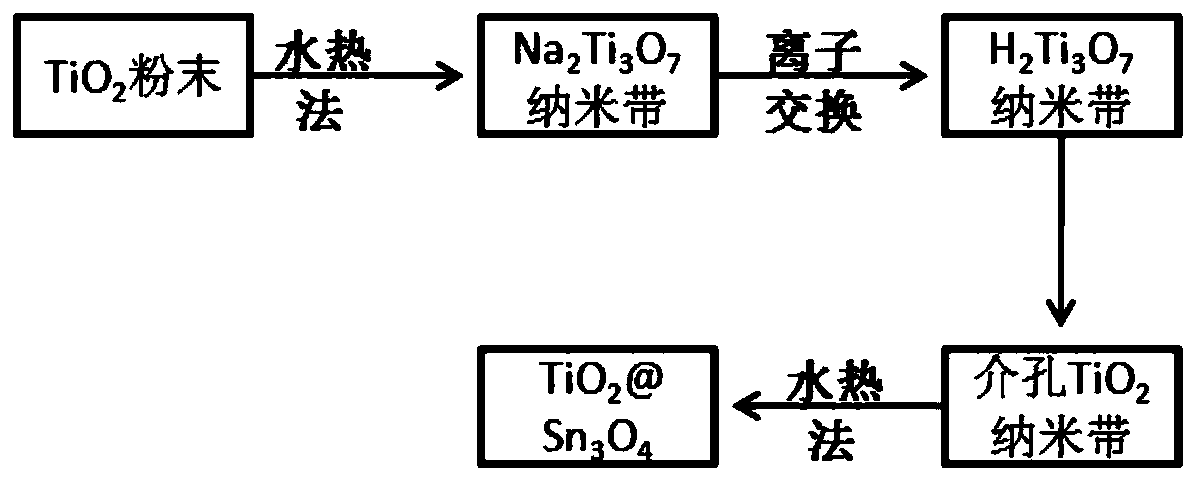

[0040] (1) A certain amount of commercial TiO 2 The powder is added to a molar concentration of 10±0.1molL -1 NaOH aqueous solution, stirred until completely dissolved; among them, TiO 2 The molar ratio of powder to NaOH is 1:80;

[0041] (2) Place the solution obtained in step (1) in a hydrothermal kettle with a certain volume and heat it up to 180°C at a heating rate of 8-10°C / min, and naturally cool to room temperature after reacting for 24 hours; wherein the solution and the hydrothermal kettle The volume ratio is 80:100;

[0042] (3) Wash the solid in the product obtained in step (2) several times with deionized water, place the washed product in a vacuum oven at 50-60°C and dry to constant weight, and grind to obtain Na 2 Ti 3 o 7 nanobelt;

[0043] (4) adding the product obtained in step (3) to a molar concentration of 1 ± 0.1molL -1 In aqueous HCl solution, stirred for 24h; where, Na 2 Ti 3 o 7 The volume ratio of nanobelts and HCl aqueous solution is 1:3.

...

Embodiment 2

[0055] (1) A certain amount of commercial TiO 2 The powder is added to a molar concentration of 10±0.1molL -1 NaOH aqueous solution, stirred until completely dissolved; among them, TiO 2 The molar ratio of powder to NaOH is 1:80;

[0056] (2) Place the solution obtained in step (1) in a hydrothermal kettle with a certain volume and heat it up to 180°C at a heating rate of 8-10°C / min, and naturally cool to room temperature after reacting for 24 hours; wherein the solution and the hydrothermal kettle The volume ratio is 80:100;

[0057] (3) Wash the solid in the product obtained in step (2) several times with deionized water, place the washed product in a vacuum oven at 50-60°C and dry to constant weight, and grind to obtain Na 2 Ti 3 o 7 nanobelt;

[0058] (4) adding the product obtained in step (3) to a molar concentration of 1 ± 0.1molL -1 In aqueous HCl solution, stirred for 24h; where, Na 2 Ti 3 o 7 The volume ratio of nanobelts and HCl aqueous solution is 1:3.

...

Embodiment 3

[0068] (1) A certain amount of commercial TiO 2 The powder is added to a molar concentration of 10±0.1molL -1 NaOH aqueous solution, stirred until completely dissolved; among them, TiO 2 The molar ratio of powder to NaOH is 1:80;

[0069] (2) Place the solution obtained in step (1) in a hydrothermal kettle with a certain volume and heat it up to 180°C at a heating rate of 8-10°C / min, and naturally cool to room temperature after reacting for 24 hours; wherein the solution and the hydrothermal kettle The volume ratio is 80:100;

[0070] (3) Wash the solid in the product obtained in step (2) several times with deionized water, place the washed product in a vacuum oven at 50-60°C and dry to constant weight, and grind to obtain Na 2 Ti 3 o 7 nanobelt;

[0071] (4) adding the product obtained in step (3) to a molar concentration of 1 ± 0.1molL -1 In aqueous HCl solution, stirred for 24h; where, Na 2 Ti 3 o 7 The volume ratio of nanobelts and HCl aqueous solution is 1:3.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com